Basic Info.

Product Description

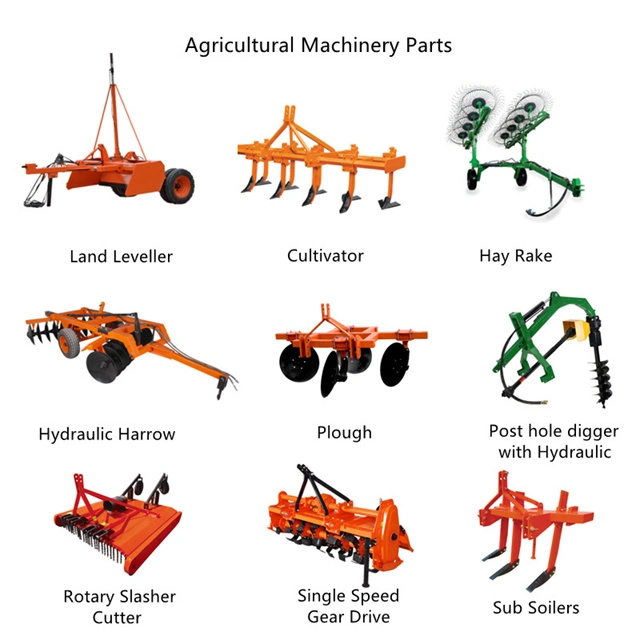

Product Photos

Product Detail

Product Description | |

Type | Casting |

Application | agriculture machinery\ construction machinery\ mining machinery and so on |

Material | Gray cast iron, nodular cast iron |

Weight | 1-500kg |

Machine Tolerance | Controlled by ISO 2768-mk |

Design Support | Auto CAD, Solid works, PDF |

Casting Tolerance | CT10-13 |

Standard | ISO9001 |

Process | Casting + Machining + Zinc Plate |

Service | OEM |

Product Process

Sand casting is a casting-based manufacturing process that involves the use of a sand mold. It's used to create metal products and components in a variety of sizes and shapes. Half of all metal castings - about 60% - are produced using sand casting. Below, the steps of sand casting.

Sand preparation → mold making → core making → pouring → shaved sand → daring processing → inspection

Other Casting parts

Quality Control

1.All specification is designed by professional engineers.

2.All material is processed by skilled workers and advanced CNC lathe.

3.All cylinders are 100% tested before package to ensure every cylinder is qualified for its purpose.

4.Package is air cushion film for each cylinder, and wooden case or steel pallet for all cylinders to ensure goods can arrive at customer safely.

5.One year warranty and long time track service is offered to solve any problems of after sale.

Packaging & Shipping

1. Packing: Air cushion film+ Steel Pallet or Plywood Case or Carton

2. Shipping: By sea, By air, or By express.

About Company

Qingdao Ruilan specialize in OEM customize casting parts that used in agriculture machinery\ construction machinery\ mining machinery and so on.

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

We can offer OEM service,please offer us below data:

a. casting parts size:

b. casting parts material:

c. casting parts drawing:

d. the quantity of casting parts

Company Other Products

FAQ

1. who are we?

We are based in Shandong, China, start from 2011,sell to South Asia(8.33%),Southern Europe(8.33%),Northern Europe(8.33%),Central America(8.33%),Western Europe(8.33%),Eastern Asia(8.33%),Mid East(8.33%),Africa(8.33%),Southeast Asia(8.33%),Eastern Europe(8.33%),South America(8.33%),North America(8.33%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Welding Mathinery attachment and equipment, Hydraulic cylinder, Railway Casting,Railway wagon,steel casting,iron casting,Precision Casting

4. why should you buy from us not from other suppliers?

professional weding machinery attachment and equipment supplier, hydraulic cylinders,casting parts, welding parts, forging parts

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese,Russian