Basic Info.

Product Description

Product Description for eddy current used aluminum beverage/bear cans(UBC) sensor separator

The Eddy Current Separator (ECS) is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminium and copper from dry recyclables.

Those particular eddy current beveragen cans sorting machine can produce higher purity and increased yield of better separation of aluminum cans from PET plastic beverage containers.In nowdays it is bacame the most economical beverage bottle sorting and recycling equipment.

Standard Features and Benefits for eddy current non-magnetic recyclables sorting machine

1. Designed with top grade NdFeB or permanent rare earth magnet material , having high-strength magnetic field and long life

2.Non-ferrous metal recovery in refuse streams and ash streams in Waste-to-Energy facilities,can up 98% recovery rate of aluminum cans from commingled recyclables

3.Import main parts:Nord Gear Motor,NSK Bearing,Seigling Belt Electric

4.Rugged heavy-duty construction effectivily reduce belt long-term wear.

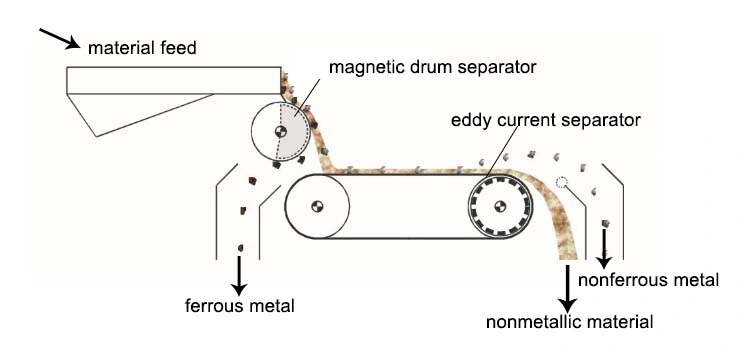

Working principle

When a piece of non-ferrous metal, such as aluminum, passes over the separator, the magnets inside the rotor rotate past the aluminum at high speed. This forms eddy currents in the aluminum which in turn create a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the nonmetallics, allowing the two material streams to be separated.

Important: When looking at an Eddy current separator, the waste travelling over the magnetic must be in a thin layer to allow the magnetic perform to its best, in case processed metal waste is mixed with ferrous metal. The Ideal format for any metal separation is first magnetic ferrous discharge, onto a vibration conveyor to spread out and further separate the remaining metals to allow the Eddy current magnetic to work at its optimal efficiency.

Also Particle size can matter, since the eddy current depends on surface area. Pieces of scrap that are a half-inch in size or larger work best.

Application for concentric pole system separators

Separate aluminum,Stainless steel, copper, brass metals from shredder residue and fluff, wildy used in municipal recycling facility (MRF) municipal solid waste facility (MSW), scrap residue and other recyclables(auto shredding residue operations, glass cullet, electronic scrap, UBC reclamation, etc)

- Separation of non-ferrous metals in auto shredder residue

- Separation of non-ferrous metals from solid waste incinerator ash

- Sorting of aluminium beverage cans from non-magnetic recyclables

- Removal of non-ferrous contamination from crushed glass cullet

- Separation of non-ferrous dross from foundry sand

- Non-ferrous metal removal in WEEE recycling plants

- Removal of aluminum components in UPVC window recycling

- Separation of non-ferrous metals from wood waste

- Separation of non-ferrous metals from plastics

- Separation of non-ferrous metals from electronic scrap

- Separation of non-ferrous metals from car recycling applications

More recommendation

|  |  |

| Eccentric Pole type Eddy-Current The magnetic pole system arranged eccentrically in the magnetic rotor of the non-ferrous metal separators concentrates the effect of the magnetic alternating fields exactly in the area at which the material is experiencing the greatest force impact and is located at the discharge point from the conveyor belt. Adjustability of the pole system enables this position to be optimally configured to the current feed material, | High-Intensity Concentric ECS In eddy current separators with a concentric rotor design, the magnet is placed in the center of the outer shell (pulley) so that the alternating magnetic field encompasses the whole 360 degrees of the shell. | Ultra High-Frequency Eddy Current Separator recovers ultra-fine aluminum, copper and other nonferrous fines materials typically missed on traditional eddy current separators from ASR . with a large number of magnetic poles operating at higher rpms creates ultra high-frequency changes resulting superior separation of fine nonferrous and even bare copper wire. |

Besides Used Beverage Can (UBC) and food can separation from municipal solid waste, Which industrial branches can the Magnetic Separator and Eddy Current Separator be use of in?

| Recycling and waste processing | Machining and foundry industry | Thermal power plants | Paper industry | Tobacco industry |

| Ceramic and glass industry | Mining and quarrying industry | Cement and lime industry | Chemical industry, paints and lacquers | Wood industry |

- Recovery of iron and steel scrap using shredder systems for shredded mixture scraps

- separation and sorting for every task in Auto shredder residue: ASR

- Recovery of non-ferrous metals for recycling & secondary smelting

- Effective recovery & quality improvement of aluminium scrap

- Cable recycling: Optical sorting technology for recycling cables

- .Separation & sorting through all fractions in electrical scrap">

- Automatic sorting valuable residues recover valuable materials from household and commecial waste ,also for Separation and sorting recycling incineration bottom ash foundry residues

- Sorting & recycling of valuable materials from construction and demolition waste

- Plastic /glass sorting equipment for metal removal recycling

more details , please kindly calling +86 15242300557