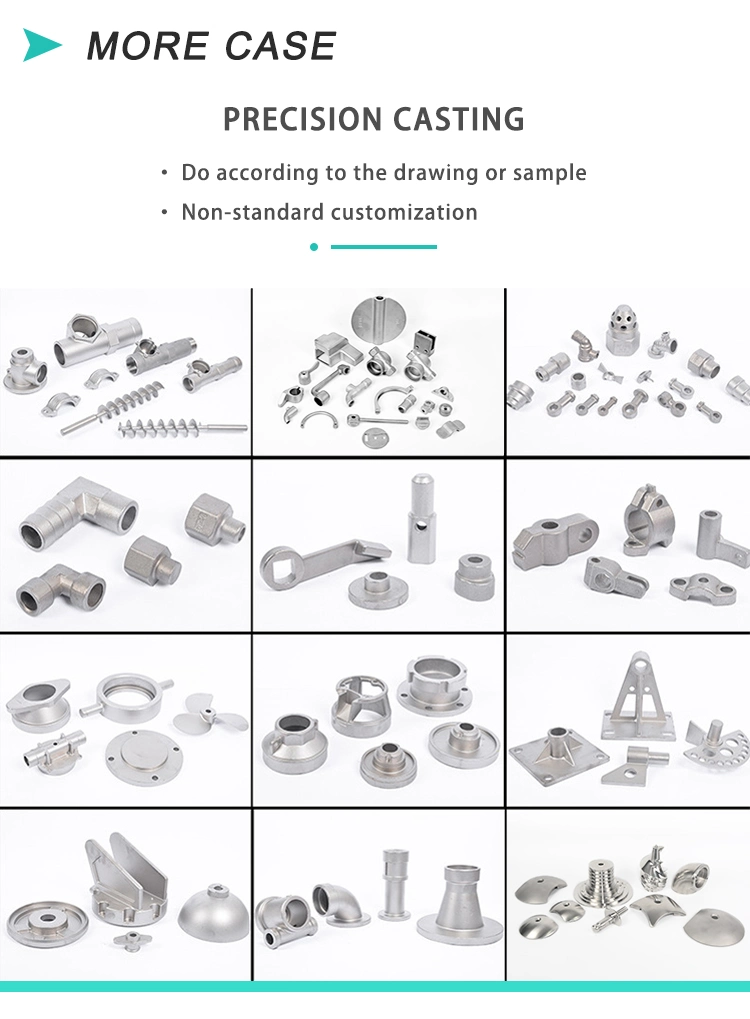

- Overview

- Product Description

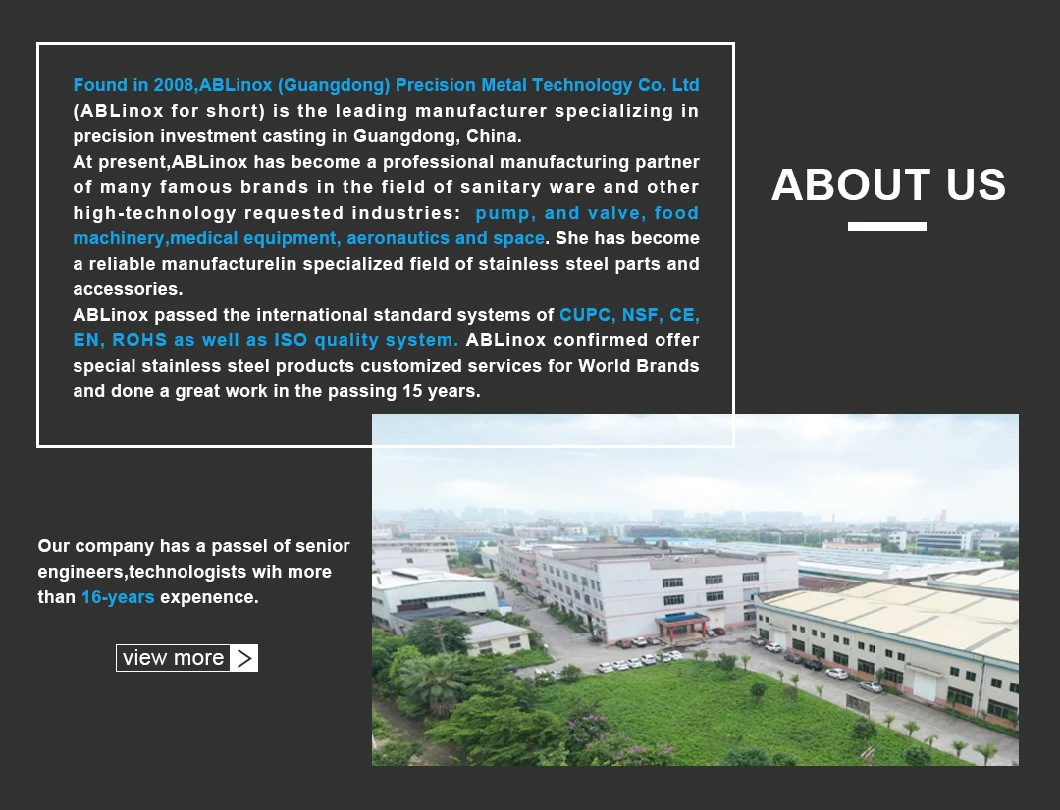

- Company Profile

Basic Info.

Model NO.

casting67

Application

Hardware

Material

Stainless Steel

Surface Preparation

Polishing

Surface Roughness

Ra0.4

Machining Tolerance

+/-0.01mm

Standard

AISI

Certification

CE, RoHS, ISO 9001:2008

Casting

Investment Casting

Weight

0.3kg-100kg

Machining Service

Available

Stainless Steel Casting

Silica Sol Casting

Transport Package

Cartons

Specification

CE, ROHS, SGS

Trademark

Ablinox

Origin

Guangdong, China

HS Code

7325999000

Production Capacity

180-250ton/Month

Packaging & Delivery

Package Size

8.00cm * 7.00cm * 1.50cm

Package Gross Weight

0.350kg

Product Description

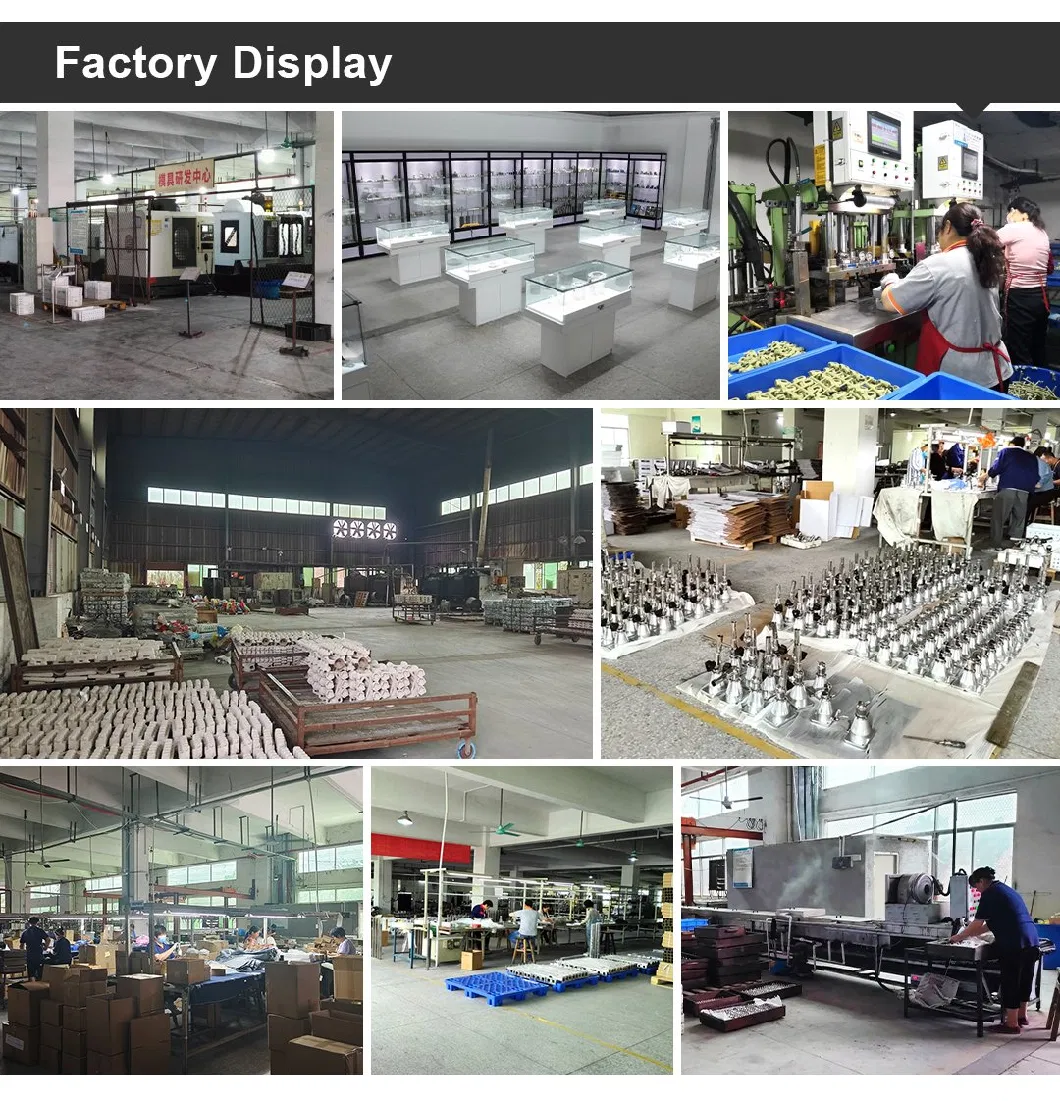

1.With our own stainless steel investment casting production lines and machining lines, give you one stop services.

2.With CNC(CNC CENTER),we make the tooling by ourselves.Make you easiler.

3.With 50000 square meters workshop located in Zhaoqing city, near Guangzhou port, transportation is convenient.

4. Production workshop: including ordinary stamping, precision high-speed stamping, laser cutting, laser welding, drilling, tapping, CNC processing, butt welding, argon arc welding, CNC turning, surface grinder processing, cylindrical grinder processing, mirror polish processing, etc.

5.We have 15 engineers with strong ability in design and develop new products.

6.With ISO 9001:2015, ISO 14001 and OHSAS 18001 system.

7.With ERP system,We can give you the production and delivery information at the first time. Also if any quality problem,We can source it and give you the solution very fast.

8.Fast reply within 12 hours.

9.Use Germany Spectrometer and Salty Spray to test the raw material.

10 Production workshop: including ordinary stamping, precision high-speed stamping, laser cutting, laser welding, drilling, tapping, CNC processing, butt welding, argon arc welding, CNC turning, surface grinder processing, cylindrical grinder processing, mirror polish processing, etc.

| material components | ||||||

Chemical Composition of Material | Material Composition | 201 | 202 | 304 | 316 | 430 |

| C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.035 | ≤0.12 | |

| Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

| P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

| S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

| Cr | 13-15 | 14-17 | 18-20 | 16-18 | 16-18 | |

| Ni | 0.7-1.1 | 3.5-4.5 | 8-10 | 10-12 | ||

| Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

| Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

| Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

| Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

| Hardness (HV) | <105 | <100 | <90 | <90 | ||