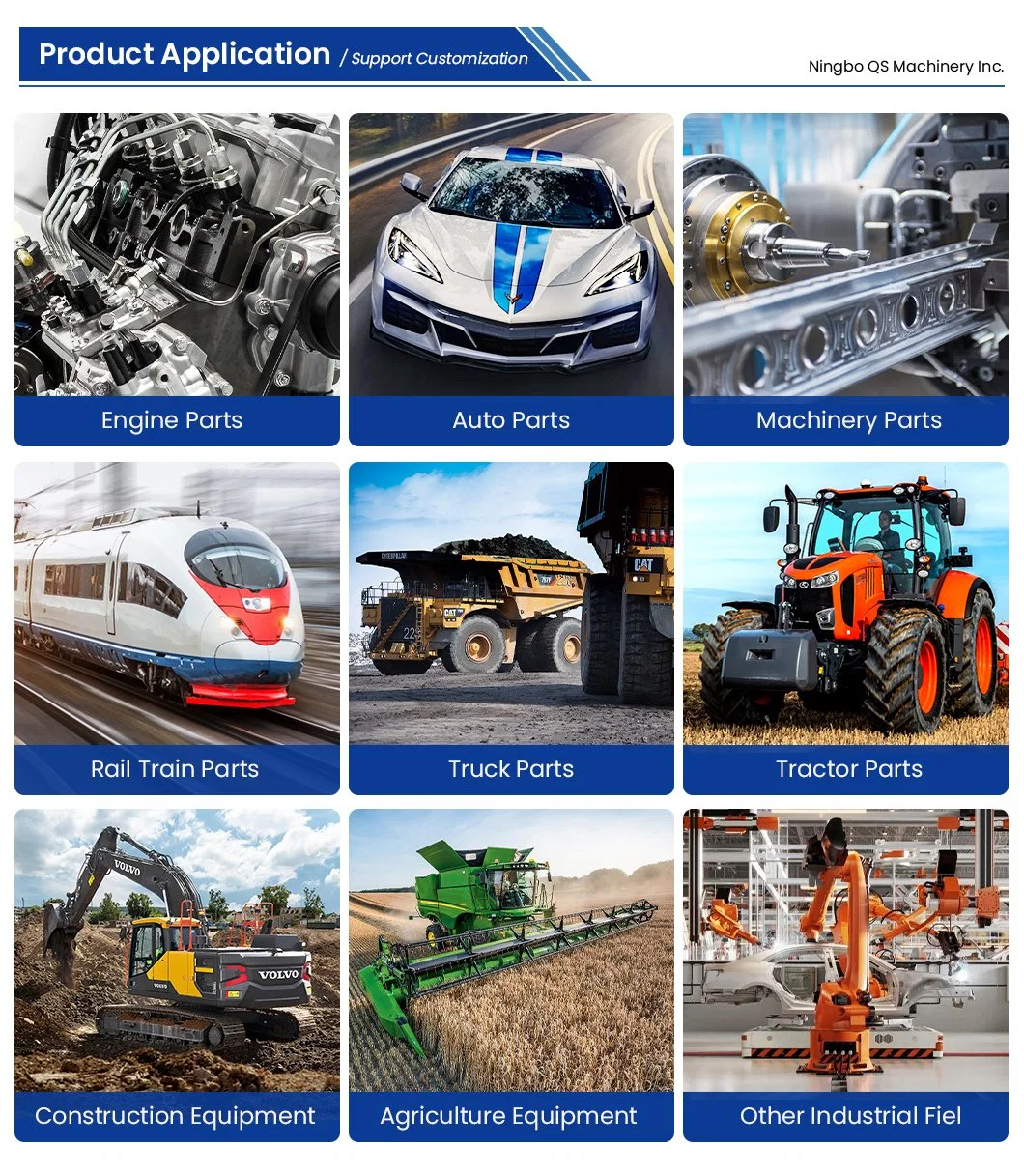

- Overview

- Our Service

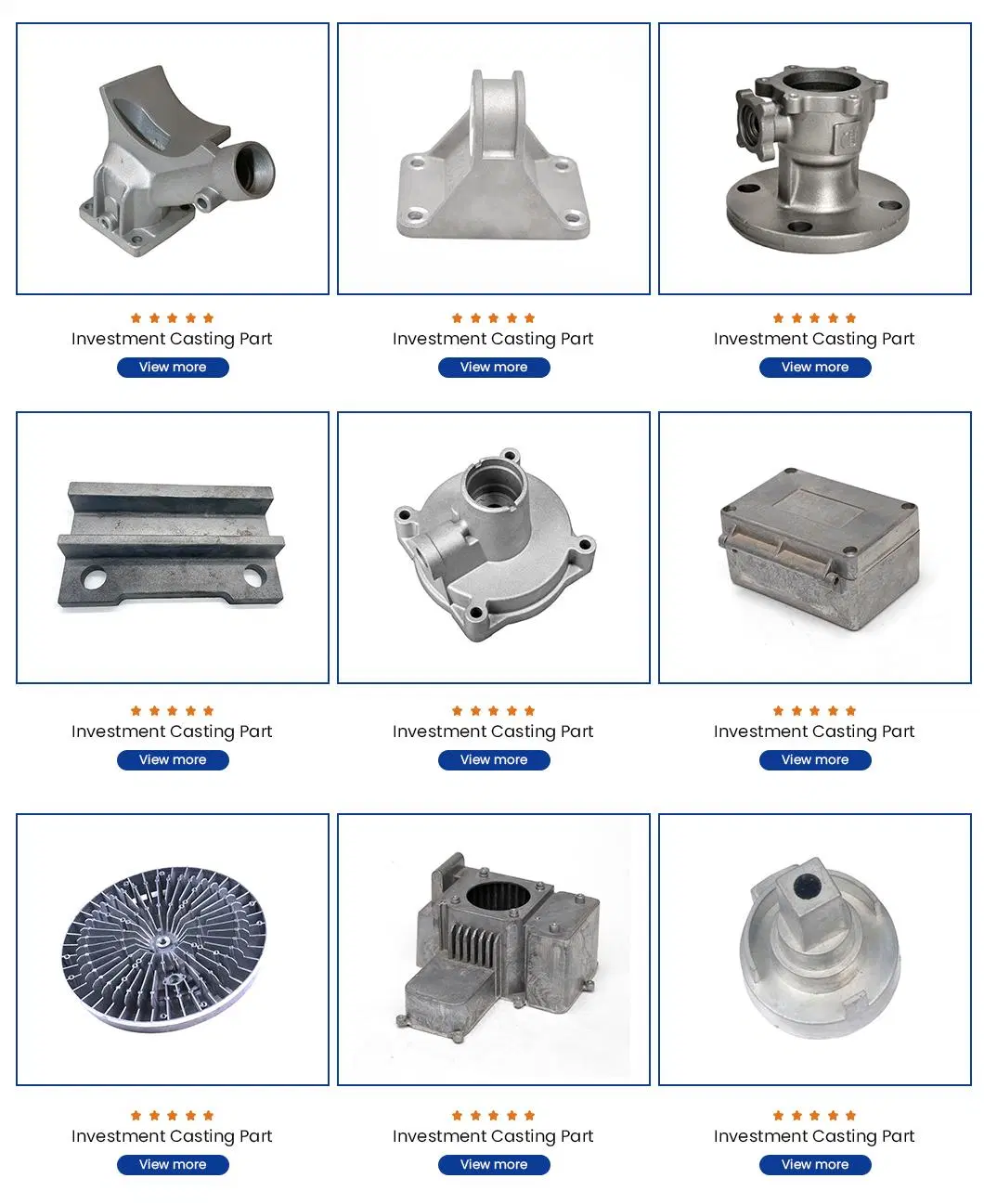

- Related Products

- Product Parameters

- Detailed Photos

- FAQ

Basic Info.

Model NO.

Investment Casting Valve Part

Surface Roughness

Ra0.2

Machining Tolerance

+/-0.01mm

Standard

GOST

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Product Name

Investment Casting Valve Part

Keywords

Investment Casting

Design

as Per The Customer′s Design

Size

Customer′s 3D Drawing

Tolerance

Strictly Casting Tolerance

Dimensions

Customized Dimension

Quality Control

100% Inspection

Product Certification

Both Material and Dimension Report

QC

100% Strict Inspection for Every Processing

MOQ

100 PCS

OEM Service

Accept

One-Stop Service

Accept

Color

Customized Color

Surface Treatment

Customizable

Transport Package

Standard Export Packing or Customized

Specification

ASTM, AISI, SAE, UNS, NF, DIN-EN, JIS, KS, SS, BS

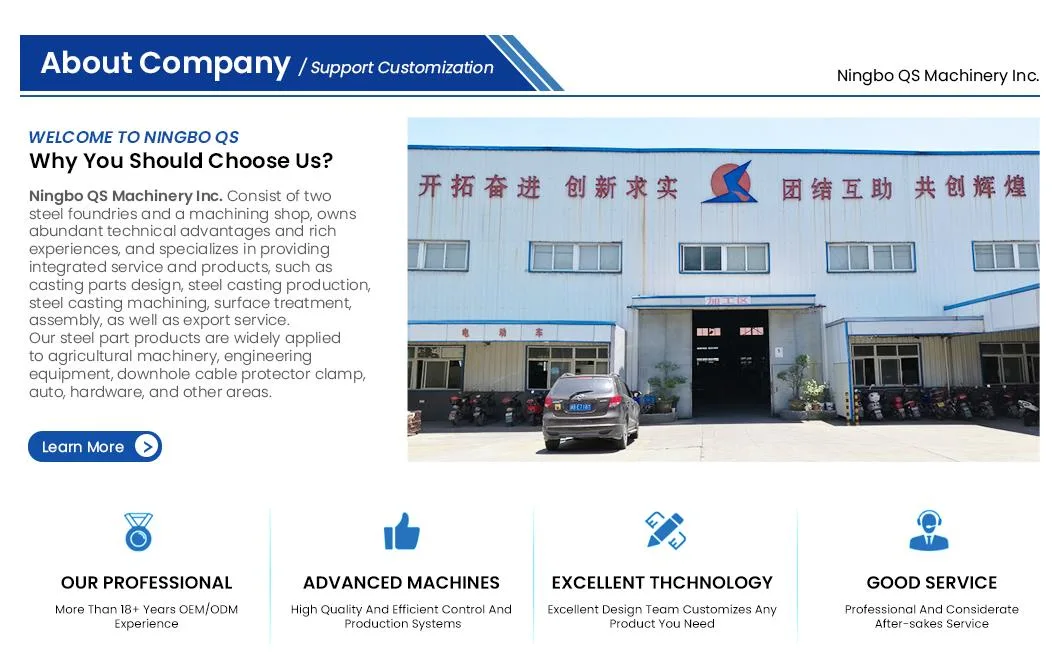

Trademark

QS Machinery

Origin

Ningbo, China

Production Capacity

600ton/Month

Product Description

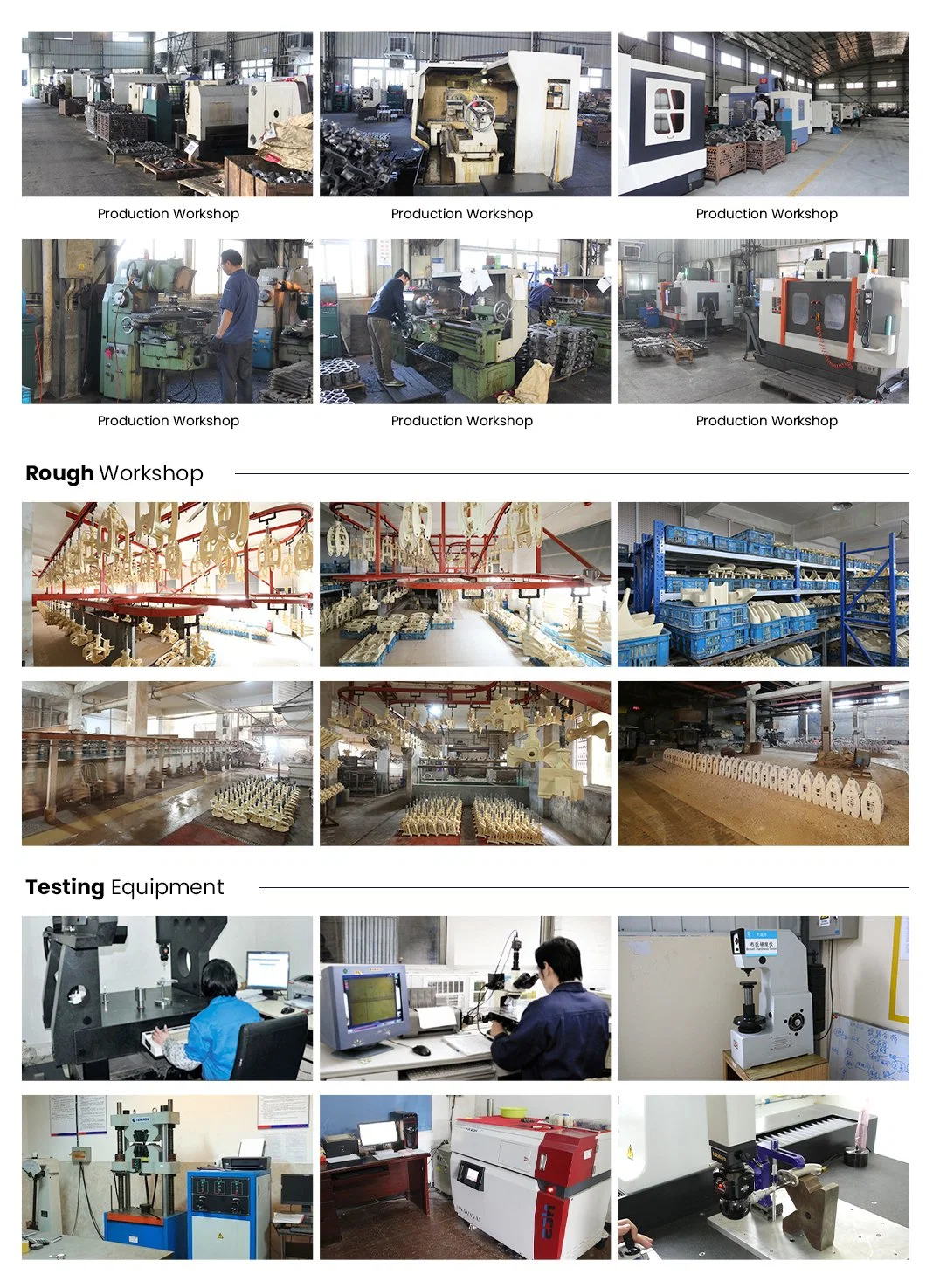

What Is Investment Casting?

Steel Investment Casting Is A Precision Casting Process, Also Known As "Melted Wax Casting" Or "Lost Wax Casting". It Is A Method Used To Manufacture High-Precision, Complex-Shaped, And High-Quality Steel Parts.

This Casting Process Works By Making A Wax Pattern Of A Precise Shape And Then Coating The Wax Pattern With Layers Of Ceramics And Other Materials To Create A Mold. Afterward, By Heating The Mold, The Wax Pattern Melts And Flows Out Of The Mold, Forming A Hollow Model.

Next, The Foundry Worker Pours The Molten Steel Into The Cavity Created On The Surface Of The Wax Pattern And Waits For It To Cool And Solidify. Once Curing Is Complete, The Mold Is Destroyed Or Dissolved, Leaving A Steel Casting Of Precise Shape And Size.

What Is Investment Casting Processes?

Ningbo QS Machinery provides steel Castings From 0.1 Kgs To 80 Kgs, Within Various materials of Carbon Steel, Low Alloy Steel, and Grey Iron For Seed Drills, Rotary Tillers, Mulchers, Cultivators, And Precision Planters.

The Advantages Of Investment Casting