- Overview

- Product Description

- Detailed Photos

Basic Info.

Model NO.

Lost Wax Castings

Special Use

High Temperature Application

Usage

Heat Treatment Furnace

Process

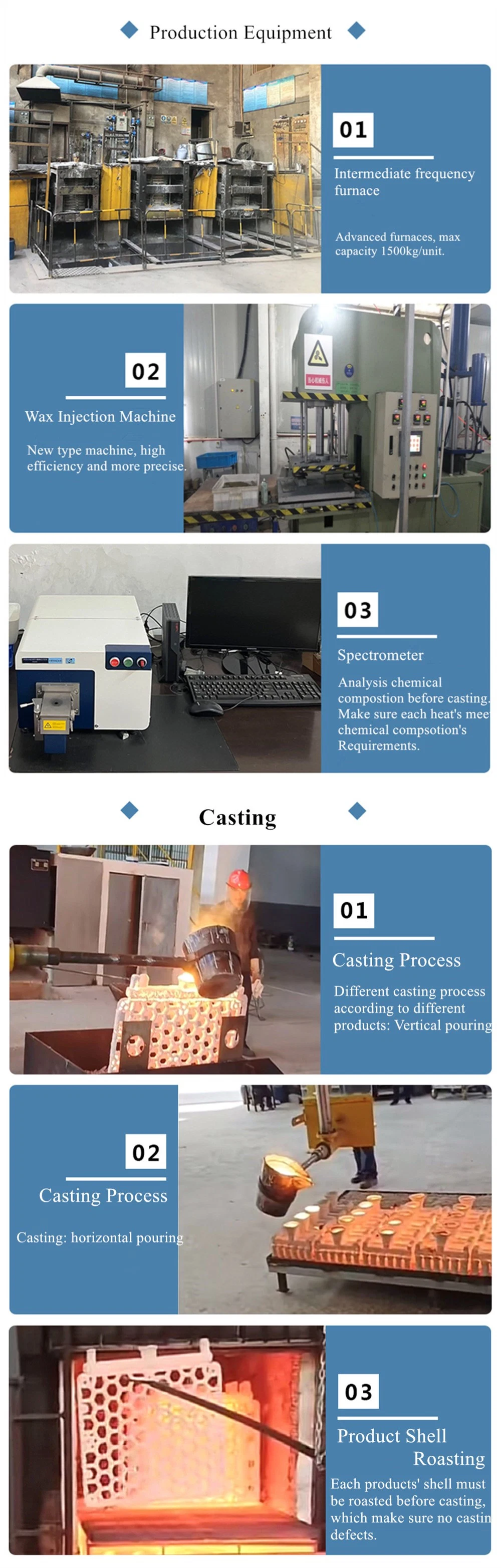

Precision Casting or Investment Casting

Working Temperature

600-1250 Celsius Degree

Outside Surface

as Cast or Fabricated

Customization

According to Provided Drawings

Transport Package

Irom Frame Panel Wood Box

Specification

According to drawings

Trademark

none

Origin

China

HS Code

8514909000

Production Capacity

50000 PCS/Year

Product Description

Lost Wax Casting Heat Resistant Alloy Cast Steel Furnace Spare Parts:

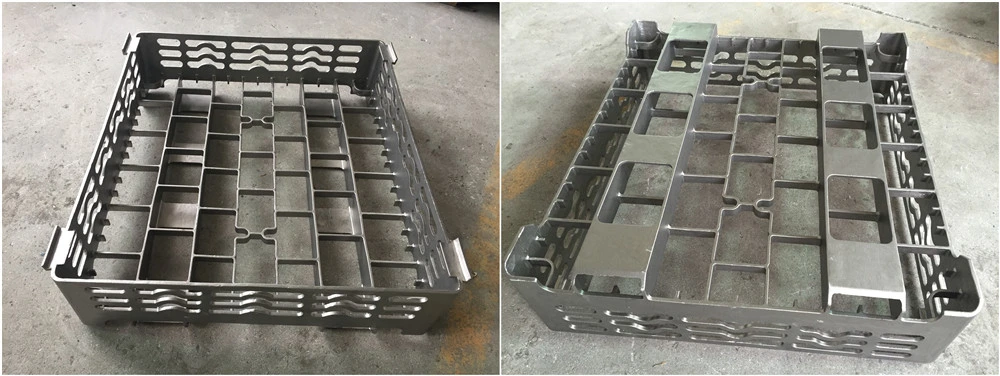

base tray, grids, baskets, fans, fixtures for industrial furnaces

| Lost Wax Castings | Lost Wax Casting is a casting method with wax mold, it provides a better surface and inside structure compared to traditional investment casting or sand castings. We specilize in heat resistant alloy steels castins for high temperatures application mainly, wax lost casting made mainly. |

| Shapes | Different shapes: - Baskets individually, assemblied, with mesh net etc - Others heat treatment furnae parts: Base Trays, Intermediate Grids, Baskets, Fans, Cast Link Belts etc. |

| Material | Heat resisting alloy steels, stainless steel, wear resistant alloy steel etc - HF, HK, HN, HP, - 1.4848/1.4849/1.4852/2.4879, - SCH22, SCH13, SUPER22H, MORE 2 etc. |

| Making Option | We can make and supply castings by follow methode: - Centrifugal castings; - Sand Castings; - Lost Wax Castings; - Investment Castings; - Fabricated. |

| Inspection | - Chemical Composition, - Visual Inspection; - PT if needed; - Dimension Inspection; |

| Packing | Panel Wood Boxes |

| Delivery | 30-75 days depends on quantity. |

Lost Wax Casting Heat Resistant Alloy Cast Steel Furnace Spare Parts

Others Heat Resisitant Alloy Steel Products we make and supply.

Different kinds of heat resistant alloy steel products made of centrifugal casting, precision casting, investment casting, static casting, welding etc.

Products such as:

- Heat Treatment Fixtures, Trays, Base Grids, Baskets,Vventilation Fans etc used at different kinds of heat treating furnaces, material of HK,HP,MORE2, 1.4848/1.4852/2.4879, SCH22 etc;

- Reformer Tubes used at refinery and hydrogen making equipments HK, HP-Nb, 1.4848/1.4852 etc,

- Cracking Furnace Tubes used for ethylene cracking furnaces made of HP, 1.4852 etc,

- Furnace Rolls used at Continious Annealing Line, Continious Galvanizing Line, Different Heat Treatment Furnaces etc

- Slide Blocks /Skidding Riders used at pusher type reheating furnaces made of HK, CO20, Co50 etc,

- Retorts /Muffle for heat treating furnaces made of HK, 1.4848, AISI 310 steel etc through centrifugal casting, investment casting, welding.

- Alloy Cast Steel Spools used at aluminum foils /copper foil / thin steel plate rolling mill made of centrifugal casting, material of 35CrMo, 35CrNiMo, KCP-12 etc

- Others anti-wear alloy steel, heat resistant alloy steel products made of centrifugal casting, precision casting, investment casting, sand casting etc.