- Overview

- Company Profile

- Product Description

- Our Advantages

- FAQ

Basic Info.

Packaging & Delivery

Product Description

We specialized in silica sol investment casting with more than 20 years

| Built year | 1998 |

| Employees | >300 |

| Investment casting Lost wax casting | 120 tons/month. Standard:ASTM,SAE,AISI,ACI,DIN,EN,ISO ZG1Cr13/1.4308/CF3M/CF8M/304/316L/17-4PH/1.4542/1.4849/16MnCr5/42CrMo4/4140/4340/SUS410/SUS420 Brass alloy:C87500,C87600,C92600,C95500,C95400,C93200 Mainly cast stainless steel,carbon steel,heat resistant steel alloy lost wax casting brass,bronze alloy,pipe fittings. Lost wax casting 1.4308 (CF8), 1.4408 (CF8M), 1.4301 (SS304), 1.4401 (SS316), and 1.4404 (SS316L) |

| Sand casting | Disa-matic line and SINTO line,2000 tons/month,grey iron and malleable iron,pipe fittings |

| CNC Machining | Turning machines,CNC machines,vertical turning mache,wire cutting machine,drillng machines,punching machines,saw machine,cutting machine |

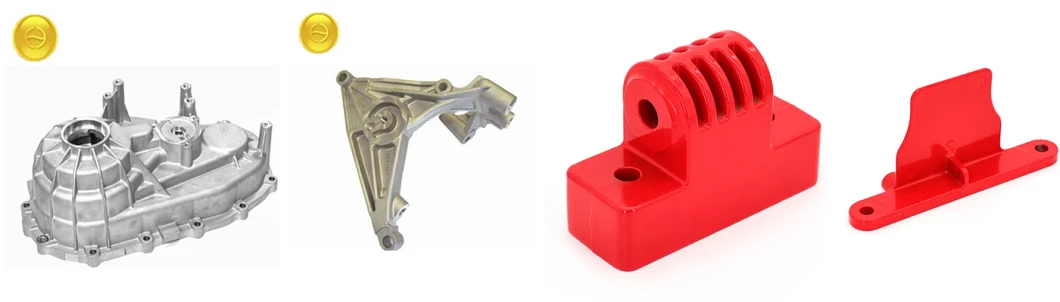

| Die casting | Zinc,alumnium,A356,ADC12,100 tons/month,share-holding company |

| Punching,Stamping,laser cutting | Laser cutting machines,punching machines |

Precision Lost Wax Investment Casting Stainless Steel Casting With CNC Machining In House

Precision Brass Copper Bronze Casting Aluminum A356 Stainless Lost Wax Steel Investment Casting

1.Auto castings

Truck / EGR Racing parts:Investment casting/lost wax casting/precision casting,surface coating,Dacromet,GEOMET,sand,glass bead and shot blasting.

2. Flow control industry

Pump components:Investment casting,soluble core,stainless steel SUS304,SUS316 housing,cover,impeller,CNC in house.

Valve accessories:Investment casting,soluble core,stainless steel,CF8M,CF3M,WCB.

3. Hardware industry

Stainless steel polished hardware:surface mirror/brush polished stainless steel hardware,tactile indicator

4. Machinery parts:42Crmo4 steel alloy casting

5. Die casting: Zinc,aluminium alloy casting,surface power coating

6. Craft art castings: cast from stainless steel,surface mirror polished

6. Craft art castings: cast from stainless steel,surface mirror polished

7. Pipe fittings:stainless steel and malleable iron pipe fittings

| One stop site | Casting+CNC+Surface treatment all in house.Gurantee the delivery time. |

| 3D Prototype | Own 3D printing machine in house,help you to develope new parts in shortly time with lower cost. |

| Experiences | More than 24 years experiences,strict quality standard,guarantee the quality. |

| Shipping | Long-relationship shipping partners from factory to all over the world. |

1.How to get the quotation ?

We need full sizes 2D techncial drawing and 3D drawing,PDF format and .stp will be the best.If you don't have,just send us samples or your ideas.

2.Delivery time ?

Mold making time is 7-15 days,samples casting time is 8-15 days,CNC machining time is 2-4 days.

3.Main market ?

Germany,Japan,USA,Australian,Italy.

4.Contact ?

E:flower^lyhszy^com