- Overview

- Product Description

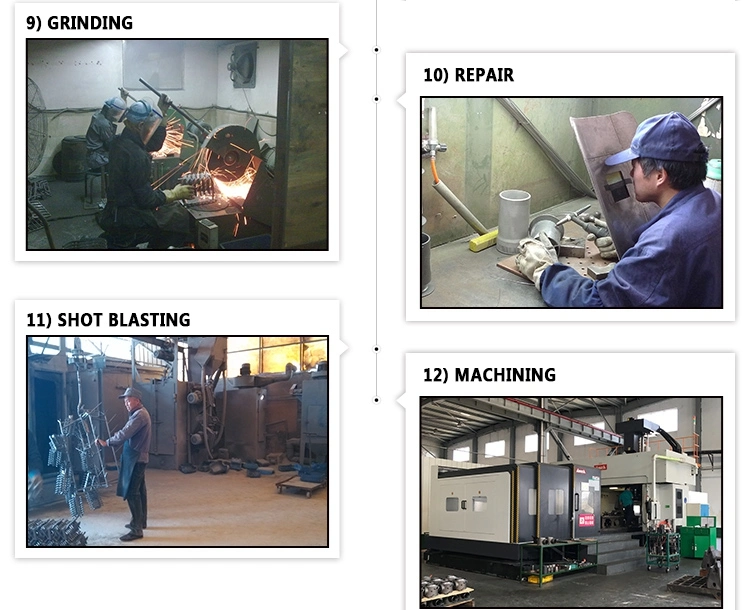

- Manufacturing Process

- Quality Inspection

- Fairs and Activities

- Packing and Delivery

Basic Info.

Model NO.

OEM/ODM

Surface Roughness

Ra3.2

Machining Tolerance

+/-0.01mm

Certification

ISO 9001:2015

Casting Tolerances

CT4-CT6

Certificate

ISO9001 SGS

Weight Range

0.5-100 Kg

Surface Finish

Shot Blasting, Powder Costing, Polishing, Brushed.

Supply Ability

150 Tons Per Month

Quality Control

Professional QC and Test Equipment

Heat Treatment

Nnealing, Normalizing, Quenching, Tempering

Machining Type

CNC Turning Milling Drilling Lathe

Use

Furniture Hardware,Machinery, Auto,Industry...

Origine

Qingdao

Delivery Time

25-30days

Package

N Pallet or as Your Requirement

Drawing Format

Step/Pdf/Igs/STP/Dwg...

Export Market

Global

Payment

T/T,Paypal, West Union

Transport Package

Bubble Bags+Cartons+Wooden Case/Pallets

Specification

15*20*25

Trademark

OEM

Origin

China

Production Capacity

150 Ton/Month

Product Description

Qingdao Xinghe Machinery Co.,Ltd was founded in 2009, which is nearly 40 mins to Qingdao port

We are specialized in customizing casting,machining,stamping, forging metal parts according to clients' drawing or samples .

Material can be aluminum, steel ,zinc, iron, brass,bronze,copper...etc

Our Advantage:

1.Rich experience in casting industry more than 10 years

2.Our engineer has 14 years' experience on casting and designing

3.Near to Qingdao Port and Qingdao Airport,saving domestic transportation costs

4.One stop service: R&D design -- Molding -- Stamping , Injection -- Assembly -- Shipping -- After-sale service

5.100% strict Inspection on both sample order and mass order

6.24 Hours on-line service

| Productive Technology | Precision Investment Casting (Silcon Sol Casting/Lost Wax Casting) |

| Material: | Carbon steel:Stainless steel; Alloy steel;Brass;Bronze;Copper |

| Casting Tolerance | CT4-CT6 |

| Machining Tolerance | ≥+/-0.05 |

| Surface Treatment: | Sand Blasting, Bead Blasting, Polishing, Brushed Polishing, Powder Coating, Galvanized Plating |

| Heat treatment: | Normalizing/Quenching/Tempering/Annealing |

| Drawing Format: | 2D drawing in PDF format/3D drawing in STEP/IGS format |

Lead time :

Mould and Samples--20-25 Days

Mass Production--30-35 Days, depending on your quanity

We have the chemical elements analysis centre and the mechanical testing centre which include the following quality control measures:

Spectrographic analysis, magnaflux crack detection, ultrasonic detection, dynamic fatigue testing, hardness testing, proof and ultimate breaking strength test... TUV DIN EN ISO 9001: 2000 & ISO/TS16949 availableIn order to ensure the quality of the orders,

our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections