Basic Info.

Product Description

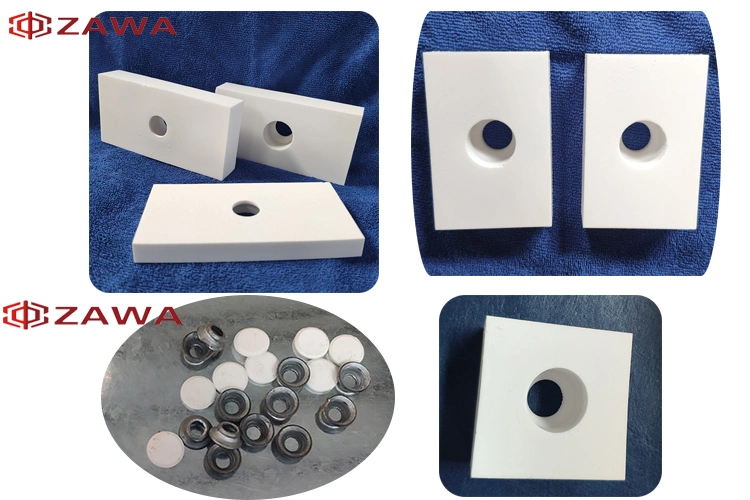

High aluminum wear-resisting brick alumina shaped ceramic parts for ball mill

Technical data of Ceramic alumina lining brick / ceramic weldable tile liner plate

| Category | 92 Series | 95 Series | ZTA | ZrO2 |

| Al2O3 | ≥92% | ≥95% | ≥74% | / |

| ZrO2+Ye2O3 | / | / | ≥23.5% | ≥95% |

| Density | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥4.15g/cm3 | ≥6g/cm3 |

| Mohs hardness | 9 | 9 | 9 | 9 |

| Water absorption% | ≤0.02 | ≤0.02 | ≤0.01 | 0 |

| Bending Strength MPa | 255 | 275 | 500 | 900 |

| Compression strength MPa | ≥850 | ≥900 | 1400 | 2200 |

| Fracture Toughness MPam 1/2 | 3.65 | 3.75 | 5.5 | 7 |

| Wear Volume | ≤0.55cm3 | ≤0.50cm3 | ≤0.15cm3 | ≤0.1 |

Brief introduction of Ceramic alumina lining brick / ceramic weldable tile liner plate

is formed by isostatic pressing with super fine alumina particles after spray granulation, and sintered in our 60m long tunnel kiln at extremely high temperature.

Ceramic alumina lining brick / ceramic weldable tile liner plate is very safe and reliable in the case of high temperature corrosion, high temperature wear or high temperature melting corrosion. Under the same working and mining conditions, its service life is ten to twenty times of that of cast stone, wear-resistant alloy cast steel, steel plastic, steel rubber and other materials.

Production Process of Ceramic alumina lining brick / ceramic weldable tile liner plate

Advantages of Ceramic alumina lining brick / ceramic weldable tile liner plate

High hardness: The alumina wear-resistant ceramic sheet has a Rockwell hardness of more than HRA90, and its hardness is second only to diamond, far exceeding the wear resistance of wear-resistant steel and stainless steel.

Excellent wear resistance: its wear resistance is equivalent to 30 times that of manganese steel and 20 times that of high chromium cast iron. According to the customer's follow-up survey, under the same working conditions, the service life of the equipment can be extended by at least ten times.

Light weight: Its density is about 3.6g/cm3, which is only half of steel, which can greatly reduce equipment load.

Application of Ceramic alumina lining brick / ceramic weldable tile liner plate

Ceramic alumina lining brick / ceramic weldable tile liner plate is installed on the impact areas of conveying systems, coal pulverizing systems, ash discharge and dust removal systems of thermal power, steel, smelting, machinery, coal, mining, chemical industry, cement, port and wharf, etc.

Specification of Ceramic alumina lining brick / ceramic weldable tile liner plate

The specification and shape of Ceramic alumina lining brick / ceramic weldable tile liner plate is various based on different working conditions or customers' requirements. The following is our size range for your reference.

| Specification | Length | Width | Thickness |

| Plain tile (without hole) | 50-228 | 25-100 | 6-80 |

| Welding tile (with hole) | 50-228 | 30-100 | 10-80 |

| Pipe tile | 50-228 | 20-100 | 8-80 |

What is the company's strength?

1. Over 15-year old factory with stable product quality

2. Factory sell directly, no more middle step

3. Competitive price with good delivery time

4. Professional international sales team will give you all round services from price quotation, order arrangement, packing to quality control, from vessel booking ,documents making to custom clearance.

5. Long-term stock preparation based on market demand

Package of Ceramic alumina lining brick / ceramic weldable tile liner plate !

Company profile

Zibo Zawa New Materials Co., Ltd. is one factory located in Zibo High-tech Industrial Development Zone, Shandong Province. It is a comprehensive enterprise integrating product design, R&D, production and sales. Its main products include ZTA zirconia toughed alumina ceramic liners, zirconia ceramic liners, 95 alumina wear resistant ceramic liners, 92 alumina ceramic liners, 92 &95 alumina grinding balls, high purity alumina inert filler balls, alumina ceramic tubes, ceramic steel compound pipes, rubber backed ceramic plates , honeycomb ceramics and various special wear-resistant parts. Our annual output is around 20000tons.

The company's backbone employees have more than 15 years of industry production experience. While continuously absorbing high-level employees, they continuously carry out regular training for employees at all levels to ensure the implementation and control of industry technology and post technology. Under the guidance of scientific development and bold innovation, the company creates tremendous value for direct users, intermediate users and agents, and truly achieves a win-win situation between producers and users.

Contact us for more about Ceramic alumina lining brick / ceramic weldable tile liner plate !