Basic Info.

Material

High Manganese Steel

Color

Customized

Drawing

Original or Customized

Delivery Time

15-30 Days

Condition

New

Type

Concave

Use

Ore Mining

Machine Type

Impact Crusher

Experience

More Than 10 Years

Crusher Models

3FT, 4FT 4.25FT, 5.5FT, 6FT, 7FT

Transport Package

Steel Pallet

Specification

MN13CR2, MN18CR2, MN22CR2

Trademark

CASTEEL

Origin

China

HS Code

8474900000

Production Capacity

5000 Ton/Year

Product Description

Product Names:

Jaw Plate,Jaw Tooth, Jaw Die, Jaw Teeth, Stationary jaw , Steady Plate, Fix plate, Fixed Jaw , Swing Jaw Plate, Movable Jaw

Cheek Plate /Side Plate,side Liner,up Liner and lower Liner

Jaw Wedges /Taper Wedges, Jaw Lock

Toogle plate, toogle bearing, toogle seat.

Bowl Liner /Concave Ring, Cone Liner

Mantle Liner, Cone Liner

Blow Bar/ Hammer

Impactor Liner,Apron Liner, Impact Plate, Side Liner

Mill Liner ,SAG mill Liner,

Material Capacity & Following Standards

We Supported a wide range of alloys with different Heat treatment capabilities

Austentic Manganese steels 14%MN, MN13CR2, MN18CR2, MN22CR2 MN13CRMO, MN18CRMO, MN22CRMO

High chromium white cast irons Chrome 15%, Chrome 25%, Chrome 30% Cr25NiMo, Cr30NiMo and Etc

Alloy steels Various grades (SWB Germany)

High and low Carbon Steel

Ni-hard 2,3, 4

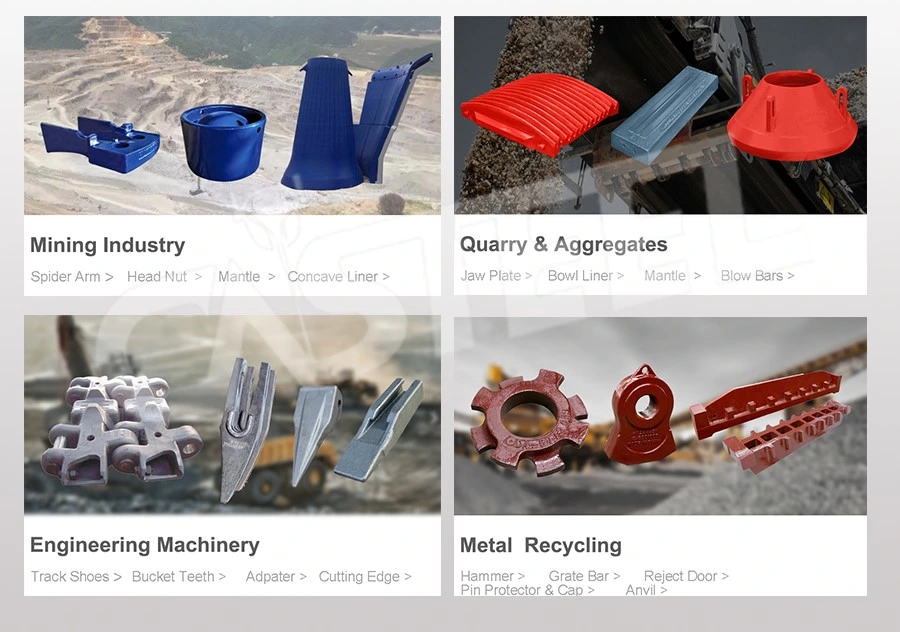

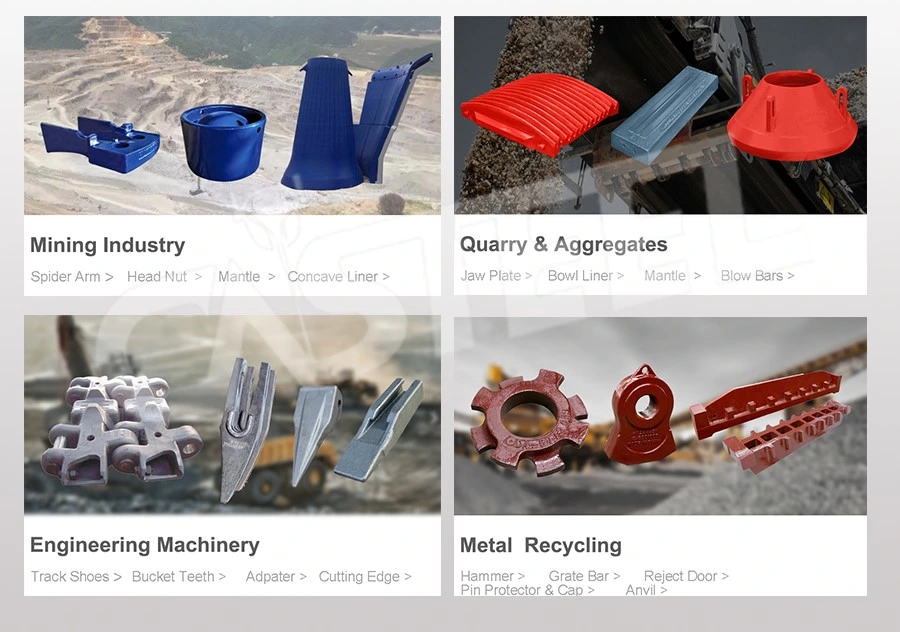

Applications:

Widely used in Mining Industry, Quarrying & Aggregate, metallurgical and Recycling industry, construction Plants, heavy engineering Industries , chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz,Basalt,Granite, Building Waste ,Metal Scrap and so on.

Design and Development Capabilities:

With professional designers and efficient mould making, we can correctly and quickly implement new product development.

Our company trained a group of professional designers, who have gotten long term training in Our company; besides professional skills,we think highly of complementary relationships on the job,and built teamwork,enabled personal experience and collective wisdom to be brought into play or productively. As a result,we can cooperate with customers,swiftly understand and work with them,also gain the trust of painters.

Support Most World famous Crusher Brands

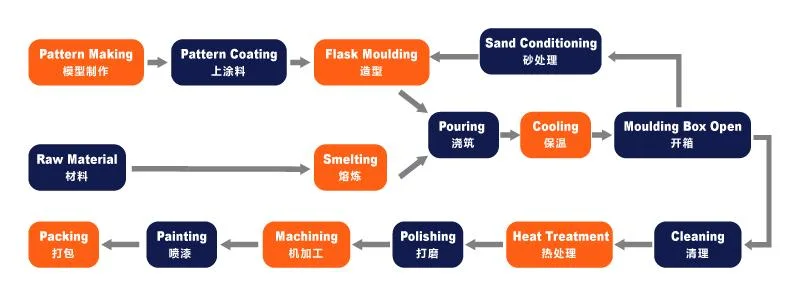

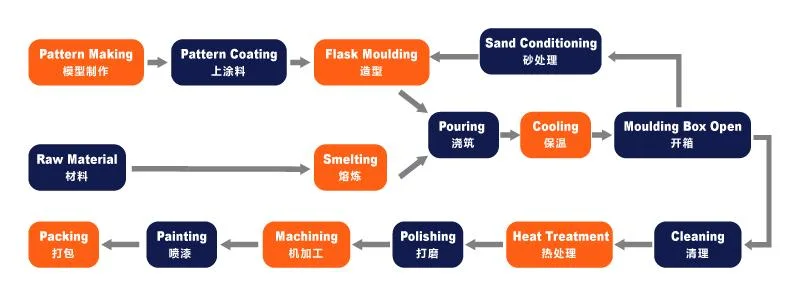

Manufacturing Process:

QC /Testing:

Provide measurement check, Metallographic, machinery performance, hardness, ultrasonic inspection, coloring flaw testing, ultrasonic flaw testing and result a report before shipping

Jaw Plate,Jaw Tooth, Jaw Die, Jaw Teeth, Stationary jaw , Steady Plate, Fix plate, Fixed Jaw , Swing Jaw Plate, Movable Jaw

Cheek Plate /Side Plate,side Liner,up Liner and lower Liner

Jaw Wedges /Taper Wedges, Jaw Lock

Toogle plate, toogle bearing, toogle seat.

Bowl Liner /Concave Ring, Cone Liner

Mantle Liner, Cone Liner

Blow Bar/ Hammer

Impactor Liner,Apron Liner, Impact Plate, Side Liner

Mill Liner ,SAG mill Liner,

Material Capacity & Following Standards

| US | Australia | British | German | South Africa | Japan | China |

| ASTM A128/A532 | AS2074 H1A/-H1B | BS3100/ BS4844 | GX 130 MnCr2 | SABS 407 Type 1 & 2 | SCMnH11 | GB/T 5680-2010 |

Austentic Manganese steels 14%MN, MN13CR2, MN18CR2, MN22CR2 MN13CRMO, MN18CRMO, MN22CRMO

High chromium white cast irons Chrome 15%, Chrome 25%, Chrome 30% Cr25NiMo, Cr30NiMo and Etc

Alloy steels Various grades (SWB Germany)

High and low Carbon Steel

Ni-hard 2,3, 4

| Material | C | Mn | Si | Cr | Molly | Nikker | P | S | Suit to |

| Mn14Cr2 | 1.0-1.3 | Mn:11-14 | 0.3-0.6 | 1.7-2.4 | --- | --- | ≤0.05 | ≤0.03 | Jaw Plate, Side Plate,Mill Liner |

| Mn14Mo1 | 1.0-1.3 | Mn:11-14 | 0.3-0.6 | --- | 0.8-1.2 | ---- | ≤0.05 | ≤0.03 | Shredder Hammer, Track Shoe |

| Mn18Cr2 | 1.1-1.4 | Mn:17-20 | 0.3-0.6 | 1.7-2.4 | --- | ---- | ≤0.05 | ≤0.03 | Jaw Plate, Bowl Liner, Mantle |

| Mn18Cr2Mo0.6 | 1.1-1.4 | Mn:17-20 | 0.3-0.6 | 1.7-2.4 | 0.6-0.8 | --- | ≤0.05 | ≤0.03 | Hard Abrassive Rock Crushing |

| Mn22Cr2Mo | 1.1-1.4 | Mn:20-24 | 0.3-0.6 | 1.7-2.4 | ---- | ---- | ≤0.05 | ≤0.03 | Heavy Duty Concave,Mantle |

| KMTBCR15 | 2.8-3.2 | Mn:0.6-0.8 | 0.6-0.8 | 14.5-15.5 | 0.2-0.3 | 0.2-0.3 | ≤0.06 | ≤0.06 | Paddle Arm ,Tip And Mixer Liner |

| KMTBCR27 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 26.5-28 | 0.3-0.5 | 0.3-0.5 | ≤0.06 | ≤0.06 | Blow Bar, Paddle tip ,VSI Parts,Anvil |

| KMTBCR30 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 28.5-30 | 0.3-0.5 | 0.3-0.5 | ≤0.06 | ≤0.06 | Blow Bar, Paddle Tip, VSI Parts |

| Cr27Ni2Mo1 | 2.8-3.3 | Mn:0.6-0.8 | 0.6-0.8 | 26.5-28 | 0.8-1.2 | 1.5-2.0 | ≤0.06 | ≤0.06 | Heavy Duty Blow Bars |

| Ni-Hard | 2.8-3.2 | 0.2-0.8 | 1.5-2.2 | 8.0-10.0 | 0.3-0.5 | 4.0-5.5 | ≤0.06 | ≤0.06 | Mill Liner, Augers, Paddle Tip |

| Martensite Alloy Steel | 0.3-0.6 | 0.8-1.5 | ≤1.2 | 1.8-2.3 | 0.2-1 | 0.5-0.8 | ≤0.06 | ≤0.06 | Blow Bar, Mill Liner and etc |

| Carbon Steel | 0.08-0.25 | 0.3-0.6 | 0.15-0.35 | ----- | ---- | ---- | ≤0.045 | ≤0.045 | Torch Ring,Shell , Bowl ,Cone |

Applications:

Widely used in Mining Industry, Quarrying & Aggregate, metallurgical and Recycling industry, construction Plants, heavy engineering Industries , chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz,Basalt,Granite, Building Waste ,Metal Scrap and so on.

Design and Development Capabilities:

With professional designers and efficient mould making, we can correctly and quickly implement new product development.

Our company trained a group of professional designers, who have gotten long term training in Our company; besides professional skills,we think highly of complementary relationships on the job,and built teamwork,enabled personal experience and collective wisdom to be brought into play or productively. As a result,we can cooperate with customers,swiftly understand and work with them,also gain the trust of painters.

Support Most World famous Crusher Brands

Manufacturing Process:

QC /Testing:

Provide measurement check, Metallographic, machinery performance, hardness, ultrasonic inspection, coloring flaw testing, ultrasonic flaw testing and result a report before shipping

| SUPPORT CONE CRUSHR MODELS | |

| Cone Crusher HP series | HP100,HP200,HP300,HP400,HP500,HP700,HP800,HP900,HP3,HP4,HP5,HP6 |

| Cone Crusher MP series | MP800,MP1000,MP1250,MP2500 |

| Cone Crusher GP series | GP100,GP100S,GP11F,GP200S,GP220,GP330,GP300S,GP550,GP500S,GP7 |

| Sandvik CH Cone series | CH420,CH430,CH440,CH660,CH830I,CH840I,CH860I,CH865I,CH870I,CH880,CH890I,CH895I |

| Svedala/Superior H Series | H2800,H3800, H4800,H6800,H7800,H8800, H36,H51 |

| Sandvik CS/S series | CS420,CS430,CS440,CS660,CS840i, S2800,S3800,S4800,S6800 |

| Terex MVP/ELJAY Series | MVP280,MVP380X,MVP450X,MVP550 X,ELJAY 45",ELJAY 54",ELJAY 66" |

| Trio TC Cone Series | TC36,TC51,TC66,TC84,TV65,TV95 |

| Terex TC/TG series | TC1000,TC1150,TC1300,TG120,TG220,TG320,TG420,TG820,TG1020 |

| Jaques Cone Series | 14",28",G35,3ft,G40,4ft,G50 or the big J65 machines and more |

| Terex Cone TGS series | TGS120,TGS220,TGS320,TGS420,RC45III |

| Pegson Cones | Pegson 900, Pegson1000, Pegson1150, Pegson1200, Pegson1300 |

| Maxtrak 1000,Maxtrak 1000SR,Maxtrak 1150,Maxtrak 1300,Maxtrak 1500 | |

| C-1540,C-1540RS,C1545,C-1550 | |

| KPI-JCI Kodiak Series | K200+, k300+ , K400+ |

| Telsmith Cone T series | T200,T300,T400,T500,T900, |

| Telsmith Cone SBS/SBX series | 38SBS,44SBS,52SBS,57SBS,68SBS,44SBX,52SBX,57SBX |

| Shanbao Cone PY/PYF series | PYB/PYD600,PYB/PYZ/PYD900,PYB/PYZ/PYD1200,PYB/PYZ/PYD1750,PYB/PYD1750 PYB/PYZ/PYD2200 |

| PYFB0910,PYFB0917,PYFD0907,PYFB1321,PYFB1324,PYFD1313,PYFB1624,PYFD1613,PYFB2133,PYFD2117 | |

| Symons Cone series | 2FT,3FT,4FT,4-1/4FT,5-1/2FT,7FT Standard and Shorthead |

| Nordberg Gyradisc Series | Gyradisc 36",Gyradisc 48"Gyradisc 54",Gyradisc 66",Gyradisc 88" Fine Crusher |

| Minyu MCC Series | MCC1000,MCF1150,MCC1300,MCSS1300 ,MCC1370,,MCC1500,MCS1500,MCC1680,MCF1680 |

| Minyu MSP Series | MSP100 ,MSP200,MSP300, MSP400 Corase , Medium and Fine |

| Minyu HN Series | MCC1000JN,MCC1150HN,MCC1300HN,MCC1370HN,MCC1500HN, MCC1680HN |

| Nakayama Cone Series | NEM40H.NCH42H, NCC45H, NEP4008H, ,NSC200,NSC300,NSC400 |

Advantages and Guarantee:

|

| 2.Quality Assurance: We give Warranty of our parts been supplied to Replace a new parts if the Parts having serious quality of crack and uncommon wearing problems. |

| 3.Wide Coverage: We have wide drawing & Pattern coverage about 80% of popular crusher models available at Market, Crusher ages can be tracked before 1950. |

| 4.Stock Availability: We Keep the VSI Parts and common crusher in stock enable us to delivery fast. |

| 5.Flexibility: We are Flexible enough to provide various payment terms to convenience our customers from different region, such as T/T, L/C, DP, Western Union , Udial as etc. and we can do the CIF shipping LCL, FCL, Airfreight, Door to door service .For FOB delivery the items to warehouse at China and can be delivery to Guangzhou and Yiwu. |

| 6.Customized: We can do customized casting according to the customer drawings and material composition. |

| 7.Services :Inspection , Property Test report , dimension report and Reverse Engineering according to customer samples. |