Basic Info.

Model NO.

Waste incineration grate block bars

Surface Roughness

Ra6.3

Machining Tolerance

+/-0.01mm

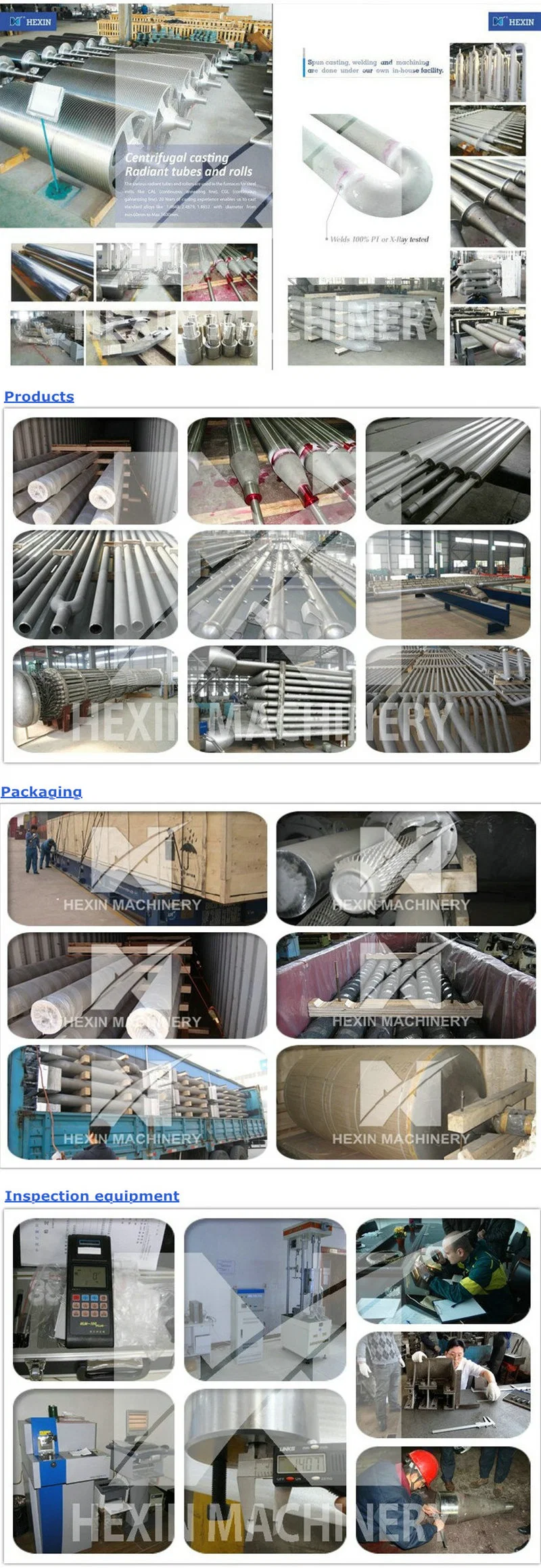

Transport Package

Wooden Case

Specification

Outer diameter: 55mm-2000mm or customized

Trademark

HEXIN

Origin

China

HS Code

85149090

Production Capacity

5000pieces/Year

Product Description

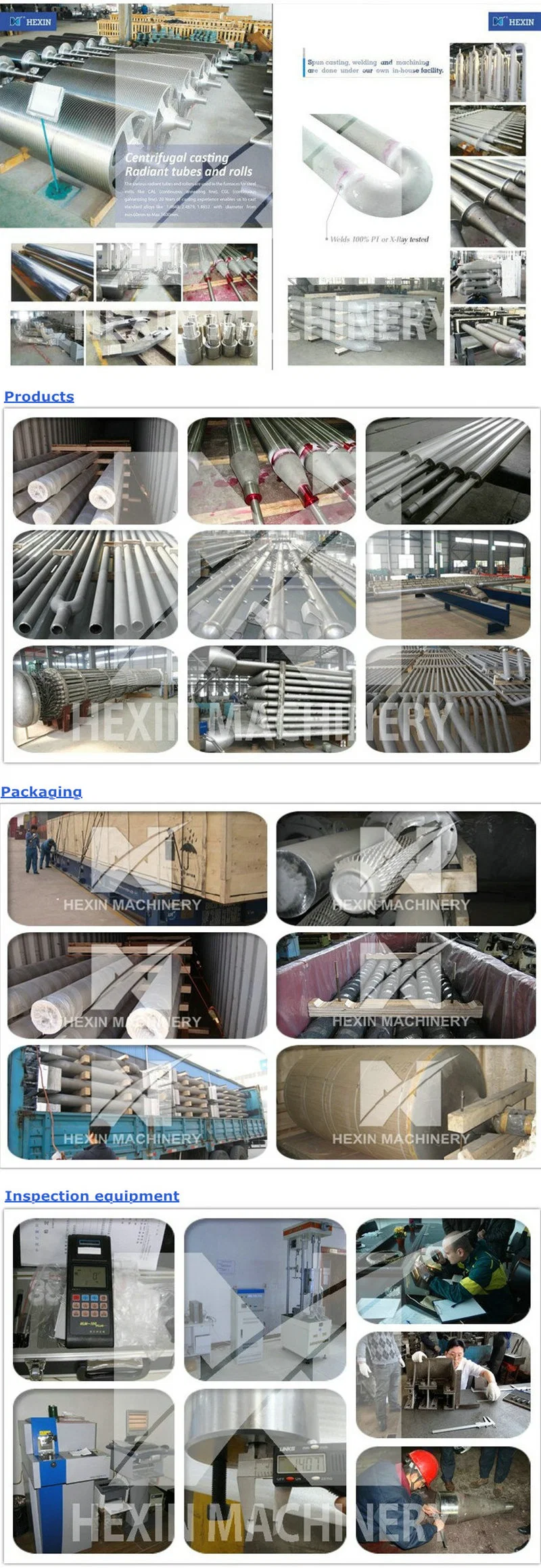

Qingdao Hexin Machinery Co., Ltd. are professional Centrifugal Casting Sink Roll for Continue Galvanizing Line, Centrifugal Casting Sink Rolls, Centrifugal Casting Rolls, Stabilizer rolls, Furnace rolls for plate heating furnace, Rolls for CAL, Water cooled rolls, Coated rolls manufacturer from China.

Qingdao Hexin Machinery Co., Ltd. produces furnace bottom rolls,which it adopt the centrifugal casting, precisely casting technology on journal bell mouth, shaft head with forging process. It can be transported with using professional wood packaging to the packing, its excellent quality has won high praise at home and abroad.

wet rolls for tunnel furnaces

HEXIN water cooled rolls have been performing well in tunnel furnaces throughout the world ,which are made by high nickel alloy tires welded to steel shaft, including a castable refractory or without the refractory.

The wet rolls perform well in atmospheres over 1300 degrees C.

The nickel alloy tires are made from heat reistant stainless steel like 2.4879, by lost wax invesment casting method with special heat treatment.

We also supply customized alloy tires or ring to customers for installation by themself.

We also produce other castigns for CSP plants, like dry rolls for tunnel furnaces, riders for walking beam or pusher type reheating furnaces in nickel and cobalt based alloys, looper rolls, run out table rolls, wrapper rolls.

Other components for plate mill and tube mills like tube mill pierce points,plate mill heat treat hardening furnace rolls, rider tiles, hearth skids, buttons, drop-out skids,recuperator boxes, recuperator tubes

The slab of the thin slab caster is cut to length and directly enters the roller hearth furnace for soaking and is transported by the hearth roller to the hot rolling mill for rolling.

Special working conditions require the product to be resistant to high temperature, pressure, and abrasion, but also to withstand the impact of the slab head and the friction

and torsion of the slab movement.

HEXIN Machinery now has full capability sand casting, centrifugal casting, precision casting, machining, riveting, heat treatment, assembly and other main workshops,

After years of development in the production of heating furnace accessories (heat-resistant steel castings),

it has provided complete sets of heating furnaces and waste heat recovery systems, as well as centrifugal casting alloy furnace tubes, radiant tubes, steam reformer tubes, steam reformer cold headers,

steam reformer inlet pigtails in Incoloy800H,Wye fittings, reducers, plug headers,and sharp bends for many refining and chemical projects of PetroChina, Sinopec, CNOOC and Sinochem.

Rich performance and experience, quality and technical ability.

Especially the large-scale heat-resistant alloy steel castings with large size, high grade and complex structure have extremely obvious advantages in technology and experience.

Centrifugal cast tubes, cast tube sheets, convection intermediate tube supports, hooks, tube sheets brackets and hangers, various furnace doors/peep doors or observation doors,

air preheaters, flue baffles, butterfly valves, quick-opening dampers, compensators, flue duct systems, etc.

Series products such as heat-resistant steel castings and cast iron plate air preheaters have a leading domestic market share and have a fairly high reputation and reputation in the industry.

Our company uses silica sol precision casting process to produce hooks, tube sheets brackets and tube sheets hangers.

The heat-resistant alloy steel castings produced by HEXIN Machinery adopts resin sand casting technology and silica sol precision casting technology.

The alloy steel castings produced by HEXIN Machinery have good surface quality, high dimensional accuracy, and no slag inclusions, sand holes,

shrinkage holes, cracks and other conventional casting defects, major products for petrochemical industry like:

Centrifugal cast tubes, cast tube sheets, convection intermediate tube supports, hooks, tube sheets brackets and hangers, various furnace doors/peep doors or observation doors,

air preheaters, flue baffles, butterfly valves, quick-opening dampers, compensators, flue duct systems, etc.

The furnace hooks are used to hang furnace tubes in heating furnaces.

They are used in high-temperature working conditions. The material has high temperature resistance like ASTM A351 Gr.HK40.

The draw tube sheet hanger is used to fix the furnace tube in the heating furnace and is installed on the side wall of the heating furnace.

It is produced by static casting process. The material has high temperature resistance. The general material is ASTM A351 Gr.HK40.

The Christmas tree tube rack is a heat-resistant alloy steel cast tube rack with a special structure.

It is called a Christmas tree tube rack because it looks like a Y-shape, like a Christmas tree. Manufactured by static casting process.

Centrifugal casting tube rack, our company uses centrifugal casting process to produce heat-resistant alloy tubes, which are used for the tube support tube racks

of horizontal tube heating furnaces.

The peep doors or observation doors are installed on the wall of the heating furnace shell is used to manually open and observe whether the burner flame in the heating furnace is normal.

The material of the fire gate is generally gray cast iron ASTM A48, which is manufactured through a static casting process.

The incinerator grate blocks bars are made from heat resistant alloy castings, yuanding use lost wax investment casting method to produce the grate blocks, with heat resistant stainless steel material nickel and chrome alloys, by aluminum mould.

With over 30 year experience with investment castings, our skilled foundry engineers always design the most suitable gating system to guarantee the inside quality of castings.

We supply various components for incineration plant furnaces, like air cooled incinerator grates, water cooled incinerator grate bars, front panels, side wall, guide beams,combustion grates, roof components,etc.,

The mechanical grate type incinerator has a variety of grate forms.

Currently, the main applications include reverse push type grate, forward push type grate, drum type grate, etc.; its main function is the reciprocating mechanical movement of the grate.

Drive the movement and turnover of domestic garbage.

At present, the mechanical grate type incinerators mainly used at home and abroad include Germany's Martin grate furnace technology, Japan's Hitachi Shipbuilding grate furnace technology, etc.

These technologies have different structures and characteristics in their core grate parts.

Compared with fluidized bed and rotary kiln incinerators, mechanical grate incinerators feature perfect and reliable technology,

large capacity, strong adaptability to waste, and convenient operation and maintenance.

About us

Qingdao Hexin Machinery Co., Ltd. is professional for manufacturing, sale and research of high temperature alloy centrifugal cast tube, Heat resistant steel precision castings and sand mold casting.

The main products are: Ethylene cracking furnace furnace tube, reformer furnace tube, all kinds of casting alloy elbow, casting tube sheet, hook, hanger, bracket and other heat resistant casting products. Furnace rollers, radiant tubes, sink roll, stabilizing roll, support arm and sleeve and other heat resistant alloy used for continuous galvanizing line(continuous annealing line), all kinds of heat treatment fixtures used for heating processing equipment, like tray, basket, fan and so on. Widely used for famous brand heat treatment equipment, such as IPSEN, AICHELIN, FONTON, etc.

We committed to the strict quality control and strictly implement ISO9000 series quality management system, Ensure the castings in each process of each station "zero defect" production, Quality has won the acceptance of customers at home and abroad.

Welcome to view our website: hexinmachineryqd.en.made-in-china.com

Qingdao Hexin Machinery Co., Ltd. produces furnace bottom rolls,which it adopt the centrifugal casting, precisely casting technology on journal bell mouth, shaft head with forging process. It can be transported with using professional wood packaging to the packing, its excellent quality has won high praise at home and abroad.

wet rolls for tunnel furnaces

HEXIN water cooled rolls have been performing well in tunnel furnaces throughout the world ,which are made by high nickel alloy tires welded to steel shaft, including a castable refractory or without the refractory.

The wet rolls perform well in atmospheres over 1300 degrees C.

The nickel alloy tires are made from heat reistant stainless steel like 2.4879, by lost wax invesment casting method with special heat treatment.

We also supply customized alloy tires or ring to customers for installation by themself.

We also produce other castigns for CSP plants, like dry rolls for tunnel furnaces, riders for walking beam or pusher type reheating furnaces in nickel and cobalt based alloys, looper rolls, run out table rolls, wrapper rolls.

Other components for plate mill and tube mills like tube mill pierce points,plate mill heat treat hardening furnace rolls, rider tiles, hearth skids, buttons, drop-out skids,recuperator boxes, recuperator tubes

The slab of the thin slab caster is cut to length and directly enters the roller hearth furnace for soaking and is transported by the hearth roller to the hot rolling mill for rolling.

Special working conditions require the product to be resistant to high temperature, pressure, and abrasion, but also to withstand the impact of the slab head and the friction

and torsion of the slab movement.

HEXIN Machinery now has full capability sand casting, centrifugal casting, precision casting, machining, riveting, heat treatment, assembly and other main workshops,

After years of development in the production of heating furnace accessories (heat-resistant steel castings),

it has provided complete sets of heating furnaces and waste heat recovery systems, as well as centrifugal casting alloy furnace tubes, radiant tubes, steam reformer tubes, steam reformer cold headers,

steam reformer inlet pigtails in Incoloy800H,Wye fittings, reducers, plug headers,and sharp bends for many refining and chemical projects of PetroChina, Sinopec, CNOOC and Sinochem.

Rich performance and experience, quality and technical ability.

Especially the large-scale heat-resistant alloy steel castings with large size, high grade and complex structure have extremely obvious advantages in technology and experience.

Centrifugal cast tubes, cast tube sheets, convection intermediate tube supports, hooks, tube sheets brackets and hangers, various furnace doors/peep doors or observation doors,

air preheaters, flue baffles, butterfly valves, quick-opening dampers, compensators, flue duct systems, etc.

Series products such as heat-resistant steel castings and cast iron plate air preheaters have a leading domestic market share and have a fairly high reputation and reputation in the industry.

Our company uses silica sol precision casting process to produce hooks, tube sheets brackets and tube sheets hangers.

The heat-resistant alloy steel castings produced by HEXIN Machinery adopts resin sand casting technology and silica sol precision casting technology.

The alloy steel castings produced by HEXIN Machinery have good surface quality, high dimensional accuracy, and no slag inclusions, sand holes,

shrinkage holes, cracks and other conventional casting defects, major products for petrochemical industry like:

Centrifugal cast tubes, cast tube sheets, convection intermediate tube supports, hooks, tube sheets brackets and hangers, various furnace doors/peep doors or observation doors,

air preheaters, flue baffles, butterfly valves, quick-opening dampers, compensators, flue duct systems, etc.

The furnace hooks are used to hang furnace tubes in heating furnaces.

They are used in high-temperature working conditions. The material has high temperature resistance like ASTM A351 Gr.HK40.

The draw tube sheet hanger is used to fix the furnace tube in the heating furnace and is installed on the side wall of the heating furnace.

It is produced by static casting process. The material has high temperature resistance. The general material is ASTM A351 Gr.HK40.

The Christmas tree tube rack is a heat-resistant alloy steel cast tube rack with a special structure.

It is called a Christmas tree tube rack because it looks like a Y-shape, like a Christmas tree. Manufactured by static casting process.

Centrifugal casting tube rack, our company uses centrifugal casting process to produce heat-resistant alloy tubes, which are used for the tube support tube racks

of horizontal tube heating furnaces.

The peep doors or observation doors are installed on the wall of the heating furnace shell is used to manually open and observe whether the burner flame in the heating furnace is normal.

The material of the fire gate is generally gray cast iron ASTM A48, which is manufactured through a static casting process.

The incinerator grate blocks bars are made from heat resistant alloy castings, yuanding use lost wax investment casting method to produce the grate blocks, with heat resistant stainless steel material nickel and chrome alloys, by aluminum mould.

With over 30 year experience with investment castings, our skilled foundry engineers always design the most suitable gating system to guarantee the inside quality of castings.

We supply various components for incineration plant furnaces, like air cooled incinerator grates, water cooled incinerator grate bars, front panels, side wall, guide beams,combustion grates, roof components,etc.,

The mechanical grate type incinerator has a variety of grate forms.

Currently, the main applications include reverse push type grate, forward push type grate, drum type grate, etc.; its main function is the reciprocating mechanical movement of the grate.

Drive the movement and turnover of domestic garbage.

At present, the mechanical grate type incinerators mainly used at home and abroad include Germany's Martin grate furnace technology, Japan's Hitachi Shipbuilding grate furnace technology, etc.

These technologies have different structures and characteristics in their core grate parts.

Compared with fluidized bed and rotary kiln incinerators, mechanical grate incinerators feature perfect and reliable technology,

large capacity, strong adaptability to waste, and convenient operation and maintenance.

| Item | Waste incineration grate block bars |

| Process | Centrifugal/spun casting method for roll body, precision casting of assembly shaft head. |

| Material | 316L,316,HK,HT,HU,HP,HH,ZG40Cr25Ni20Si2,ZG14Ni32Cr20Nb,ZG45Ni48Cr28W5Si2. |

| Application | The heat treatment furnace roll are usually used for normalizing furnace and hardening furnace, under the hydrogen nitrogen protective environment, Furnace temperature is about 900 ºC. CGL (Continuous hot dip galvanizing line),Plating aluminizing line, Plating silicon line. |

| Specifications | Outer diameter: 55mm-2000mm Length: as per your request |

| Test | Chemical analysis by spectrometer for each heat,eddy current test,pressure test ,thickness test , PT 100%(liquid penetrant test),VI(visual inspect)100%,dimensional check. |

| Products | Sink rolls Stabilizer rolls Furnace rolls for plate heating furnace Rolls for CAL Water cooled rolls Coated rolls |

About us

Qingdao Hexin Machinery Co., Ltd. is professional for manufacturing, sale and research of high temperature alloy centrifugal cast tube, Heat resistant steel precision castings and sand mold casting.

The main products are: Ethylene cracking furnace furnace tube, reformer furnace tube, all kinds of casting alloy elbow, casting tube sheet, hook, hanger, bracket and other heat resistant casting products. Furnace rollers, radiant tubes, sink roll, stabilizing roll, support arm and sleeve and other heat resistant alloy used for continuous galvanizing line(continuous annealing line), all kinds of heat treatment fixtures used for heating processing equipment, like tray, basket, fan and so on. Widely used for famous brand heat treatment equipment, such as IPSEN, AICHELIN, FONTON, etc.

We committed to the strict quality control and strictly implement ISO9000 series quality management system, Ensure the castings in each process of each station "zero defect" production, Quality has won the acceptance of customers at home and abroad.

Welcome to view our website: hexinmachineryqd.en.made-in-china.com