Basic Info.

Model NO.

Segmented Dam Ring

Material

Metal

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Transport Package

Wooden Pallet

Specification

customized

Trademark

HEXIN

Origin

China

HS Code

85149090

Production Capacity

10000pieces/Year

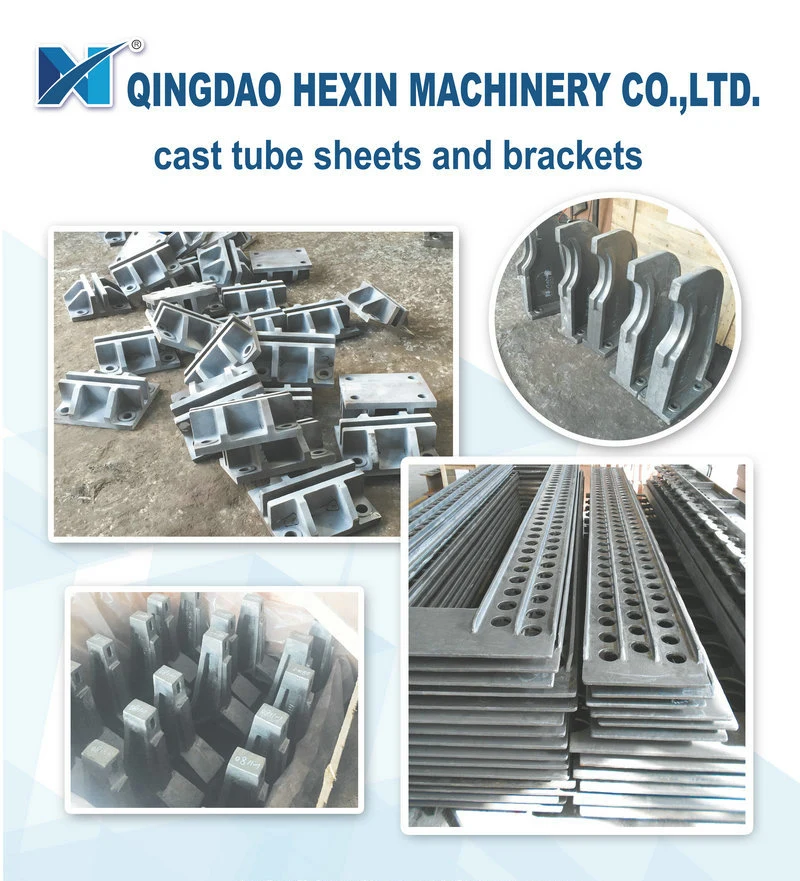

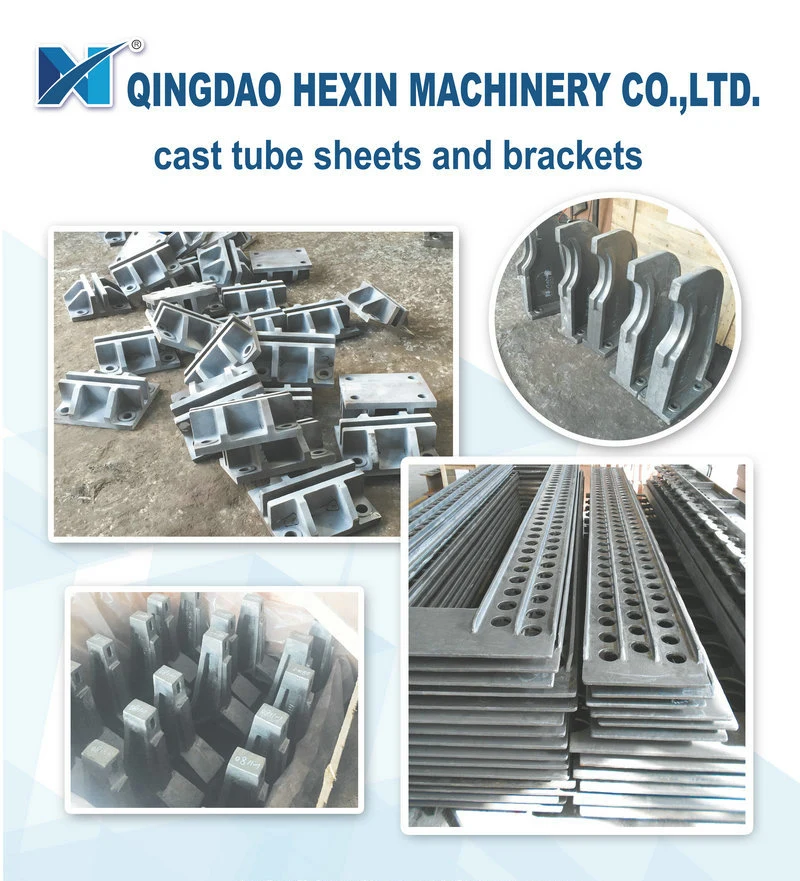

Product Description

The side guard plate of the jaw crusher is also called the fork plate and the baffle plate. Generally there are 2 pieces per machine, and there are 4 pieces; side guard This product is a kind of high-strength wear-resistant steel, which can effectively protect the machine body and extend the life of the frame. Jaw crusher side guard The side guard is located between the fixed tooth plate and the movable tooth plate. It is a high-quality high-manganese steel casting. In the whole body, it mainly protects the wall of the jaw crusher frame.

HEXIN Machinery is focusing on castings with several casting methods, like sand casting, investment casting, centrifugal casting, for various industries, with heat resistant stainless steel, wear resistant steel, etc, major products for cement plants like:

grate cooler plates, side wall plates, slit grate plates, inlet plates, cover plates, mulden plates, flange plates with air slits, honeycombs, coolax type of cooler grates, modified plates, intermediate plates, fixed and movable grate plate supports for clinker coolers.

The ball mill liner is used to protect the cylinder from the direct impact and friction of the grinding body and the material. At the same time, different forms of liner can also be used to adjust the motion state of the grinding body to enhance the grinding effect of the grinding body on the material , Help to improve the grinding efficiency of the mill, increase the output and reduce the metal consumption.

Qingdao HEXIN Machinery is focusing on castings over 15 years with several casting methods, like sand casting, investment casting, centrifugal casting, for various industries, with heat resistant stainless steel, wear resistant steel, etc, major products for cement plants like: protective segments, trust rings, roller with shafts, kiln rings, inlet outlet nose ring segments and various spares for rotary kilns.

HEXIN Machinery produces various OEM wear and corrosion resistant components for the cement, lime, coal, shot blast machines, and iron Ore industries.

HEXIN Machinery produces various OEM wear and corrosion resistant components for the cement, lime, coal, shot blast machines, and iron Ore industries.

The castings HEXIN made generally are made from special irons and manganese steels, which are critically used in the sectiors of cement manufacturing,coal mining (surface and underground), copper smelting,crushers direct reduction of iron (DRI)

Iron ore manufacturing,Lime manufacturing. All the castings manufactured at HEXIN go through strict quality checks at all stages before being supplied to customers.

Typical Mining & Mineral castings:

HEXIN Machinery is focusing on castings with several casting methods, like sand casting, investment casting, centrifugal casting, for various industries, with heat resistant stainless steel, wear resistant steel, etc, major products for cement plants like:

grate cooler plates, side wall plates, slit grate plates, inlet plates, cover plates, mulden plates, flange plates with air slits, honeycombs, coolax type of cooler grates, modified plates, intermediate plates, fixed and movable grate plate supports for clinker coolers.

The ball mill liner is used to protect the cylinder from the direct impact and friction of the grinding body and the material. At the same time, different forms of liner can also be used to adjust the motion state of the grinding body to enhance the grinding effect of the grinding body on the material , Help to improve the grinding efficiency of the mill, increase the output and reduce the metal consumption.

Qingdao HEXIN Machinery is focusing on castings over 15 years with several casting methods, like sand casting, investment casting, centrifugal casting, for various industries, with heat resistant stainless steel, wear resistant steel, etc, major products for cement plants like: protective segments, trust rings, roller with shafts, kiln rings, inlet outlet nose ring segments and various spares for rotary kilns.

| Item | Segmented Dam Ring by Hexin |

| Usage | Large inventory of cast tray patterns and designs used in all furnace types and hearth designs such as batch, continuous, pit & box. |

| Shapes | Multiple round, square, rectangular, bolted assemblies and reversible tray designs |

| Specifications | Multiple heat & corrosion resistant alloy compositions available |

| Technology | Chemical analysis by spectrometer for each heat, PT 100%(liquid penetrant test), VI(visual inspect)100%, dimensional check. |

| Material | ZG4Cr25Ni20Si2,ZG4Cr25Ni35NbW,2535W2,2848,ZG4Cr28Ni48W5Si2(2848W5),Co20 etc. |

| Products | Multy purpose furnace tray Base tray for heat treatment furnace Batch skid trays Cast furnace tray Grids baskets for heat treatment fixtures Investment casting base tray Roller hearth trays Stacking trays Tray Assemblies |

HEXIN Machinery produces various OEM wear and corrosion resistant components for the cement, lime, coal, shot blast machines, and iron Ore industries.

HEXIN Machinery produces various OEM wear and corrosion resistant components for the cement, lime, coal, shot blast machines, and iron Ore industries. The castings HEXIN made generally are made from special irons and manganese steels, which are critically used in the sectiors of cement manufacturing,coal mining (surface and underground), copper smelting,crushers direct reduction of iron (DRI)

Iron ore manufacturing,Lime manufacturing. All the castings manufactured at HEXIN go through strict quality checks at all stages before being supplied to customers.

Typical Mining & Mineral castings:

- Cooler grate plates

- Drag chain links

- Kiln outlets sector

- Immersion tubes for Pre heater

- Dipping tube assemblies

- Thimbles

- Air cannons

- Grate plates

- Drag chains

- Pelletizing grates

- Feed chutes

- Rotary cooler castings

- Burner tips

- Liners

- Brackets,

- Cooler grates

- Grate bars

- Iron ore feeder rolls

- Kiln nose rings

- Pallet cars

- Precipitator thimbles

- Traveling grate components