Basic Info.

Model NO.

355/30/100G

Material

Carbon Steel

Certificate

ISO9001:2008

Bearing Bar Dimension

20*3 to 100*8mm, Various Dimension

Bearing Bar Type

Plain/Serrated/I Type

Surface Treatment

Hot DIP Galvanized/Painted/Untreated

Bearing Bar Pitch

20-100mm

Transport Package

Naked or as Request

Specification

255/30/100

Trademark

JW or N/M

Origin

Hebei, China

HS Code

7308900000

Production Capacity

2500 Tons Per Month

Product Description

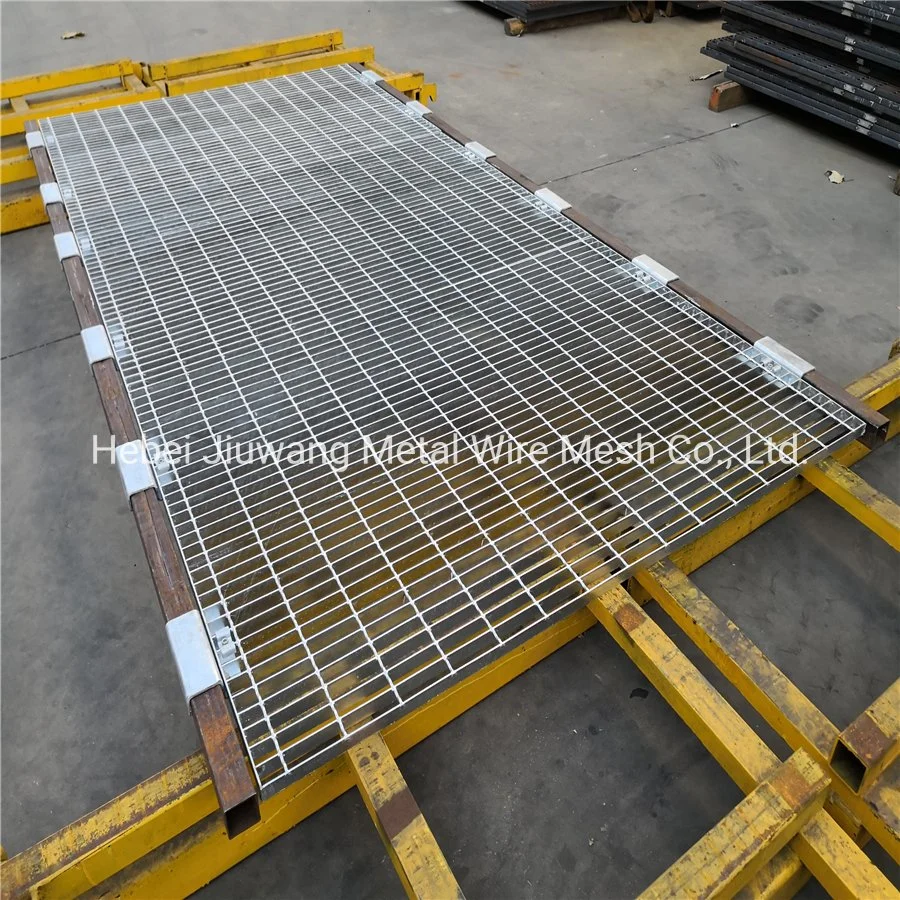

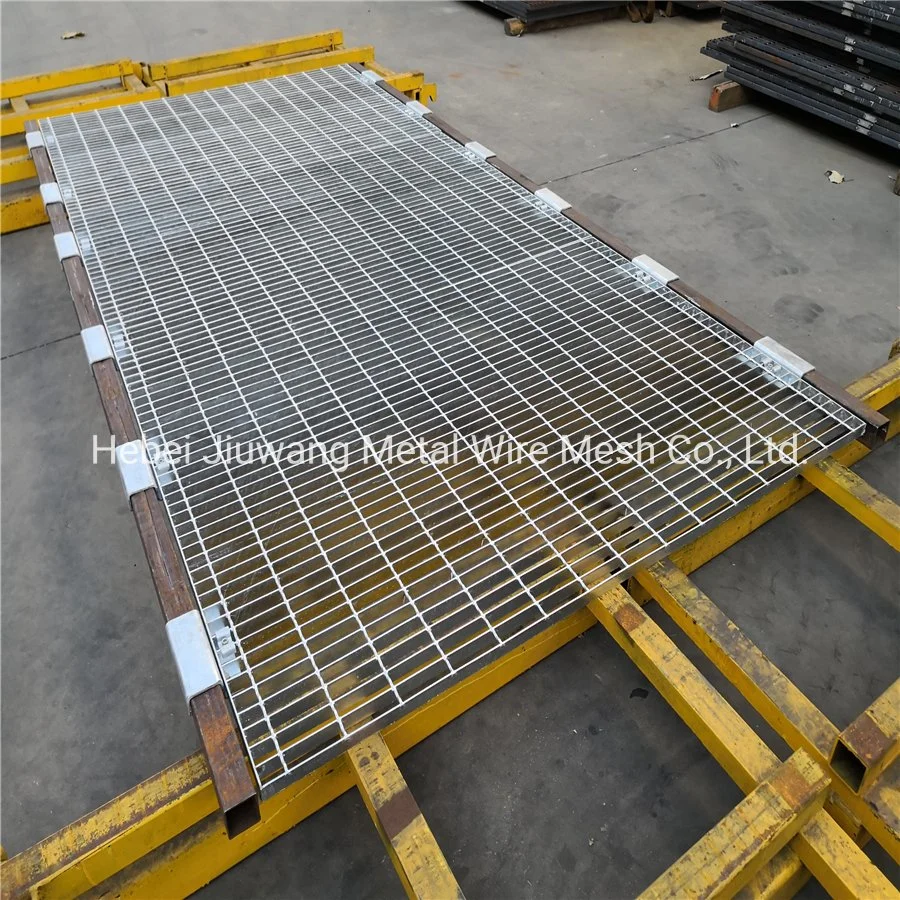

Welcome to Hebei Jiuwang Metal Wire Mesh Co, . Ltd., where we manufacture strong, safe, no-maintenance steel grating and accessories for a wide range of industrial uses. (The factory is ISO 9001: 2000 accredited. )

With more than 20 years experience, we are specilized in forging steel grating and surface treatment(hot-DIP galvanized, painting ). Our sales team, working cooperatively with our technical team, so it is able to make quotes for your projects free of charge and professionally.

Raw material: Carbon steel, mild steel, stainless steel and so on

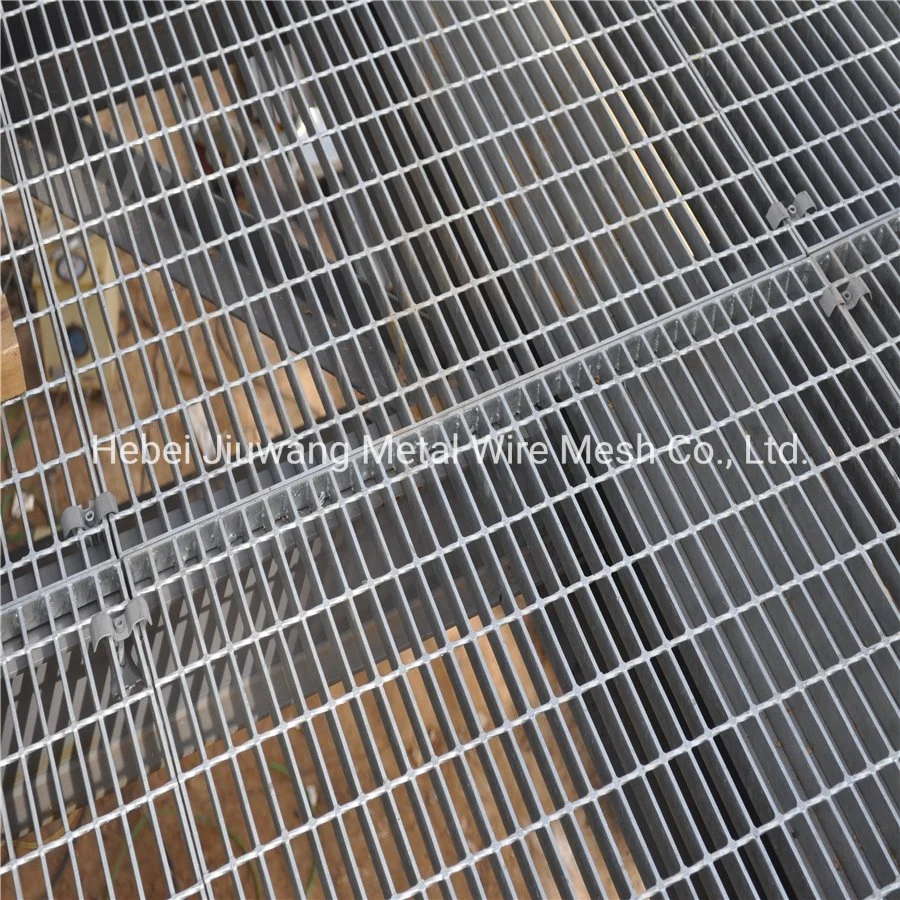

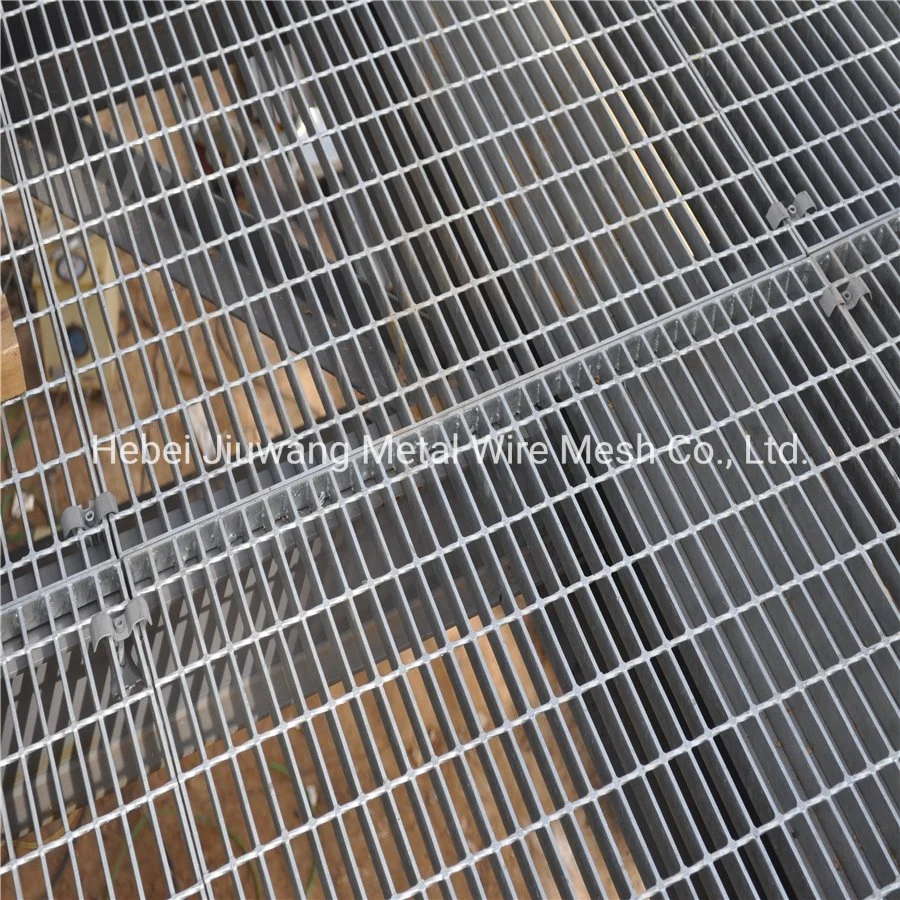

Type: Plain bearing bar(F), Ibearing bar(I), Serrated bearing bar(S), Serrated andIbearing bar(IS)

1. Material: Carbon steel or stainless steel

2. Bearing bar from 20x3mm to 100x10mm/ I section from 25x5x3mm to 75x7x4mm

3. Bearing bar pitch: 12.5mm, 30mm, 34.3mm, 40mm, 60mm or according to your requirement

Cross bar pitch: 30mm, 38.1mm, 50mm, 100mm or according to your requirement

4. General panel length: 5800mm, 6000mm, 6100mm

5. General panel width: 1000mm, 1100mm

6. Surface treatments: Untreated, painted or hot DIP galvanized

Compared with cost iron drain cover, the advantage of steel grating:

1. Saving material: the most economical method of using material at the same bearing condition, correspondingly, also less material of supporting structure.

2. Less investment: less material, less workman, shorter time limit of project, no need of clearance and maintenance.

3. Easy construction: fixed by installation fastener or welding, one person can finish.

4. Durable: hot-dipped galvanized, high attacking and heavy duty proof.

5. Modernization: beautiful appearance, reasonable design, good ventilation and daylight,

6. Light structure: less material, light weight, easy to be lifted and loaded

7. Dirt proof: no rain, no snow and dust

With more than 20 years experience, we are specilized in forging steel grating and surface treatment(hot-DIP galvanized, painting ). Our sales team, working cooperatively with our technical team, so it is able to make quotes for your projects free of charge and professionally.

Raw material: Carbon steel, mild steel, stainless steel and so on

Type: Plain bearing bar(F), Ibearing bar(I), Serrated bearing bar(S), Serrated andIbearing bar(IS)

1. Material: Carbon steel or stainless steel

2. Bearing bar from 20x3mm to 100x10mm/ I section from 25x5x3mm to 75x7x4mm

3. Bearing bar pitch: 12.5mm, 30mm, 34.3mm, 40mm, 60mm or according to your requirement

Cross bar pitch: 30mm, 38.1mm, 50mm, 100mm or according to your requirement

4. General panel length: 5800mm, 6000mm, 6100mm

5. General panel width: 1000mm, 1100mm

6. Surface treatments: Untreated, painted or hot DIP galvanized

Compared with cost iron drain cover, the advantage of steel grating:

1. Saving material: the most economical method of using material at the same bearing condition, correspondingly, also less material of supporting structure.

2. Less investment: less material, less workman, shorter time limit of project, no need of clearance and maintenance.

3. Easy construction: fixed by installation fastener or welding, one person can finish.

4. Durable: hot-dipped galvanized, high attacking and heavy duty proof.

5. Modernization: beautiful appearance, reasonable design, good ventilation and daylight,

6. Light structure: less material, light weight, easy to be lifted and loaded

7. Dirt proof: no rain, no snow and dust

| Item No. | Bearing Bar Pitch | Cross Bar Pitch | Specification of bearing bar load width× thickness | ||||||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | ||||||

| 1 | 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 | |||

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | |||||

| 2 | 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 | |||

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | |||||

| 3 | 60 | 50 | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 | ||||

| Item No. | Bearing Bar Pitch | Cross Bar Pitch | Specification of bearing bar load width× thickness | ||||||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | ||||||

| 1 | 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 | |||

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | |||||

| 2 | 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 | |||

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | |||||

| 3 | 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 | |||