Basic Info.

Model NO.

QY-TD-1034

Application

Agricultural Machinery Parts

Material

Aluminum Alloy

Surface Roughness

Ra6.3

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Tolerance

+/-0.1mm ~ +/-0.005mm

Color

Customied

Dimension

Customied

Lead Time

Depends on Quantity

Transport Package

Packing

Specification

customized

Trademark

OEM

Origin

China

Packaging & Delivery

Package Size

27.00cm * 5.00cm * 9.50cm

Package Gross Weight

1.900kg

Product Description

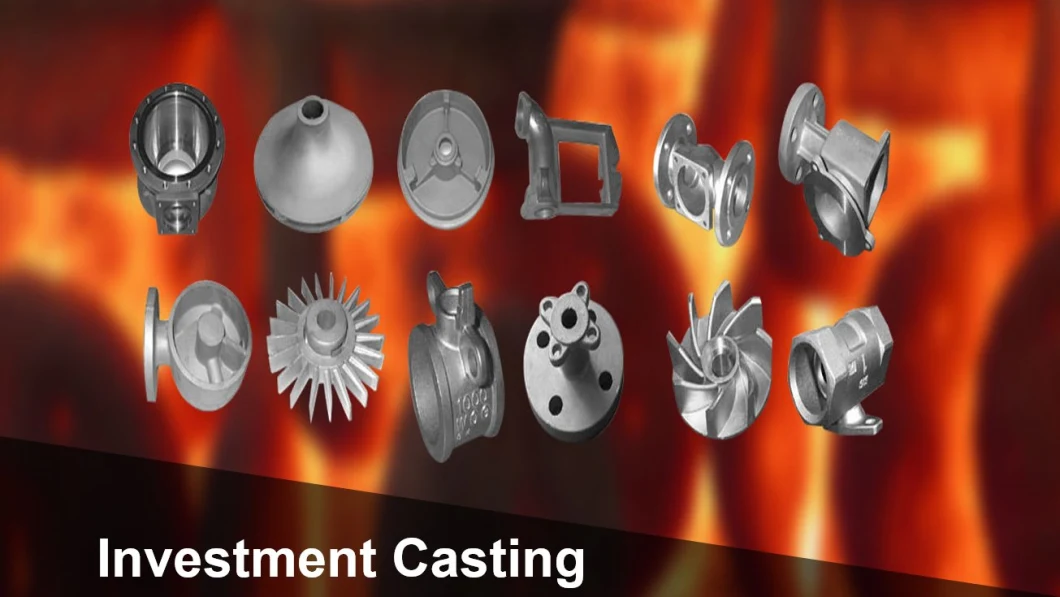

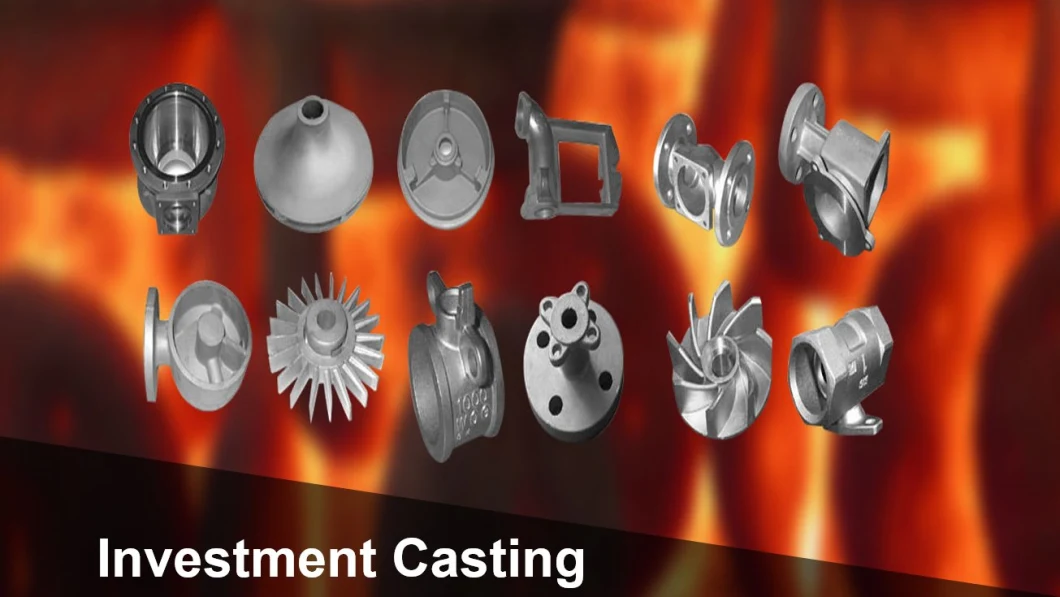

Lost Wax Investment Casting Wax Mould Casting Quality Aluminum Zinc Stainless Steel

| Product Name | cast aluminium die /gravity/sand casting process |

| Material | Ferrous materials:cast iron, grey iron, ductile iron, austempered ductile iron , carbon steel,stainless steel, low alloy steel, high chromium/manganese steel Non-ferrous: aluminum alloy, copper alloy,brass, bronze titanium alloy |

| Process | Clay sand casting,Shell molding ,Lost foam casting,Resin sand casting, CNC machining |

| Equipment | Molding machine, lost foam casting production line, CNC machining center, general machine tools,CNC laser cutting machine,large-scale press machine |

| Finish | zinc phosphide, zinc plating, hot dip galvanized, e-coating, spray paint, black oxide coating ,anodized,passivation and others |

| Testing Instrument | Spectrum analyzer, tension tester, hardness tester, three coordinates measuring instrument, caliper, micrometer, dial gauge, microscope, roughness tester, salt spray testing machine, ultrasonic flaw detector, X-ray detection machine, magnetic particle flaw detector, air tightness testing machine, thickness gauge |

| Product Application | Engineering & mining works |

| Other main casting products | Auto parts,large mining equipment accessories, engineering machinery parts, valve parts, large diameter pipe fittings, , agricultural machinery parts,construction machinery, gear box,body case etc. |

Investment Casting Process

NO:1 Metal Die Casting

Based on the drawings and requirements of the desired cast part,the metal die or mold,usually in aluminum, will be design and produced.The cavity will form the same sized and structure of desired cast part.

NO:2 Wax Injection

Also as known as pattern formation,Lost wax casting patterns are created by injecting molten wax into the metal die above.

Also as known as pattern formation,Lost wax casting patterns are created by injecting molten wax into the metal die above.

NO:3 Slurry Assembly

The wax patterns are then attached to a gating system,which usually is a set of channels through which a molten metal flsows to the mold cavity.After that,a structure like a tree is formed,which is suitable for mass production.

The wax patterns are then attached to a gating system,which usually is a set of channels through which a molten metal flsows to the mold cavity.After that,a structure like a tree is formed,which is suitable for mass production.

NO:4 Shell Building

The investment casting outer shell casing is built up through dipping into a ceramic bath and then immediately coated with sand for several times.

The investment casting outer shell casing is built up through dipping into a ceramic bath and then immediately coated with sand for several times.

NO:5 De-waxing

The inner cavity of precision investment casting is then dewaxed,which leaves a hollow outer ceramic shell layer.The hollows are just the same space as the desired castings.

The inner cavity of precision investment casting is then dewaxed,which leaves a hollow outer ceramic shell layer.The hollows are just the same space as the desired castings.

NO:6 Pre-Pouring Analysis

Pre-pouring analysis means that the foundry need to check and analyse the chemical composition of the molten metal to see if they are meet the require numbers or the stardard.some times,this analysis would be made several times.

NO:7 Pouring & Solidification

The ceramic shell with cavity should be pre-heated before pouring.This prevents shock and the ceramic shell from cracking once the liquid metal at a high temperature is poured into the cavity.

Pre-pouring analysis means that the foundry need to check and analyse the chemical composition of the molten metal to see if they are meet the require numbers or the stardard.some times,this analysis would be made several times.

NO:7 Pouring & Solidification

The ceramic shell with cavity should be pre-heated before pouring.This prevents shock and the ceramic shell from cracking once the liquid metal at a high temperature is poured into the cavity.

NO:8 Sawing or Cutting

Once the metal has cooled and solidified,the cast part is then removed from the gating system tree cluster via shaking,cutting or friction sawing off the individual cast part.

Once the metal has cooled and solidified,the cast part is then removed from the gating system tree cluster via shaking,cutting or friction sawing off the individual cast part.

NO:9

Shot Blasting and Secondary Processing

The casting part is then fully customized through grinding or additional heat treatments.Secondary machining or surface treatment might also be required depending on the requirements or the part.

Shot Blasting and Secondary Processing

The casting part is then fully customized through grinding or additional heat treatments.Secondary machining or surface treatment might also be required depending on the requirements or the part.

NO:10 Packing and Delivery

Then the lost wax casting part will be fully tested for the dimensions,surface,mechanical properties and other required tests before packing and delivery.

Then the lost wax casting part will be fully tested for the dimensions,surface,mechanical properties and other required tests before packing and delivery.