Basic Info.

Model NO.

OEM

Designing Scheme

Qos

Transport Package

Composite Board Box

Specification

Upon request

Trademark

SNMTCO

Origin

China

HS Code

810299000

Production Capacity

50 Sets/Year

Product Description

Snmtco is the leading manufacturer of powder-metallurgically processed refractory and special metals. Based on our core competences in the areas of high performance materials, emerging applications and technologies, we have been manufacturing products and components made from molybdenum, tungsten, tantalum, niobium, chromium and their alloys for more than 15 years.

Refractory metals have various beneficial properties for use in high-temperature processing equipment: high melting point and correspondingly low vapour pressure, low thermal expansion and heat capacity as well as excellent high temperature strength and creep resistance. Through the development of special high performance alloys based on Mo and W (such as TZM, MLR, WVM, etc.) Snmtco has succeeded in significantly improving the microstructural stability and creep strength in comparison to the pure metals. vacuum furnace hot zones and engineered components and offers the most extensive range of high temperature products.

Snmtco always has a comprehensive range of standard components and mill products in stock, deliveries can be made in a few days. Various material grades based on Mo, W and Ta are available.

Refractory metals have various beneficial properties for use in high-temperature processing equipment: high melting point and correspondingly low vapour pressure, low thermal expansion and heat capacity as well as excellent high temperature strength and creep resistance. Through the development of special high performance alloys based on Mo and W (such as TZM, MLR, WVM, etc.) Snmtco has succeeded in significantly improving the microstructural stability and creep strength in comparison to the pure metals. vacuum furnace hot zones and engineered components and offers the most extensive range of high temperature products.

Application Fields of Snmtco Materials

- Sintering of metals and ceramics

- Powder processing (calcining, reduction, agglomeration)

- Brazing, high-temperature annealing and heat treatment

- Metal injection moulding (MIM)

- Annealing of stainless and electrical steel in N2/H2 atmospheres

- Aerospace including maintenance, repair and overhaul (MRO)

- Medical technology

- Electronics and semiconductor industries

- Lighting industry

- Production of nuclear fuel

- Thermal waste treatment

- Research and development

Snmtco supplies the whole spectrum regarding:

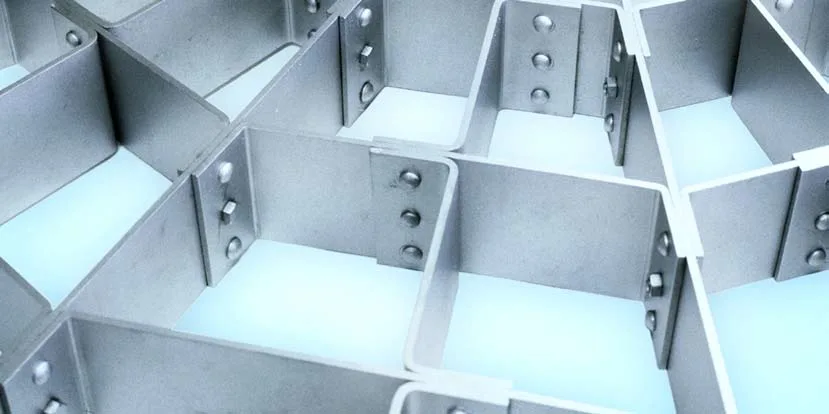

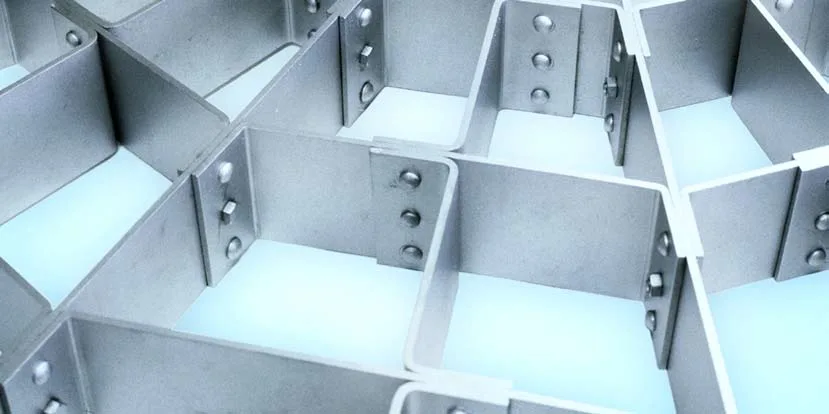

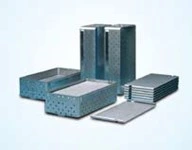

Hot Zones for High Temperature Furnaces

- Materials: Mo, W, Ta, Nb and their alloys

- Shielding/insulation: hybrid hot zones with graphite or ceramic fibre insulation

- Dimensions: hot zones ranging from very small to extremely large

- Design: round, rectangular, vertical, horizontal or special types

- Replacement of graphite with metallic hot zones (usually without needing to change the transformers)

- TIG welded stainless steel structure for support frame and plenum

- ML for components subjected to extreme thermal and mechanical load, such as heating elements, element supports, hot face and gas nozzles

- Optimum choice of the type of heating element for the given application (ribbon, sheet, wire, rod, stranded wire, mesh)

- Double V-groove design and free flowing support for wide ribbon heating elements

- Radiation shielding design guarantees low energy consumption over long-term operation

- U-rails (ML or TZM) replacing standard rails in hearth design for minimum material usage and easy sliding of the workpiece during thermal expansion

Hot Zones for High Temperature Furnaces

|  |  |  |

| Sheets, plates and foils | Rods with random or cut length | Wires and bundled wires for heating elements | Boats |

|  |  |  |

| Plates | Furnace components and spare parts | Complex engineered components | Support studs, bolts and pins |

Snmtco always has a comprehensive range of standard components and mill products in stock, deliveries can be made in a few days. Various material grades based on Mo, W and Ta are available.

-

- Sheets, plates and foils

- Rods with random or cut length

- Small parts such as screws, bolts, nuts, rivets and washers

- Rails and posts for load support

- Threaded rods

- Support studs, bolts and pins

- Wires and bundled wires for heating elements

- Tubes and thermocouple sheaths

- Ceramic isolators