Basic Info.

Model NO.

VEA017

Application

Petrochemical Machinery

Material

Stainless Steel

Surface Preparation

Sand Blast

Surface Roughness

Ra3.2

Machining Tolerance

Refer to German Investment Casting Tolerance Stand

Standard

AISI

Certification

ISO 9001:2008

Service

One Stop Service. Machining-Assembly

Customized Support

OEM

Type

Vehicle Accessories

Quality Control

100% Inspection Before Packing

Place of Origin

Foshan, China

Lead Time

30-45 Days After Payment

QC

Engineer and Inspector

CNC Machining

Accept Customized

Production Capaciy

200 Tons Per Month

Finish

De-Burr, Blasting, Polishing, Powder Coating

Weight

0.1kg up to 50kg

CNC

Drilling, Tapping, Milling, Thread

Mold

Silica Sol Zircon Sand Mixed Slurry Production

Casting Surface Quality Level

2

Heat Treatment

Quenching, Tempering, Annealing, Nor

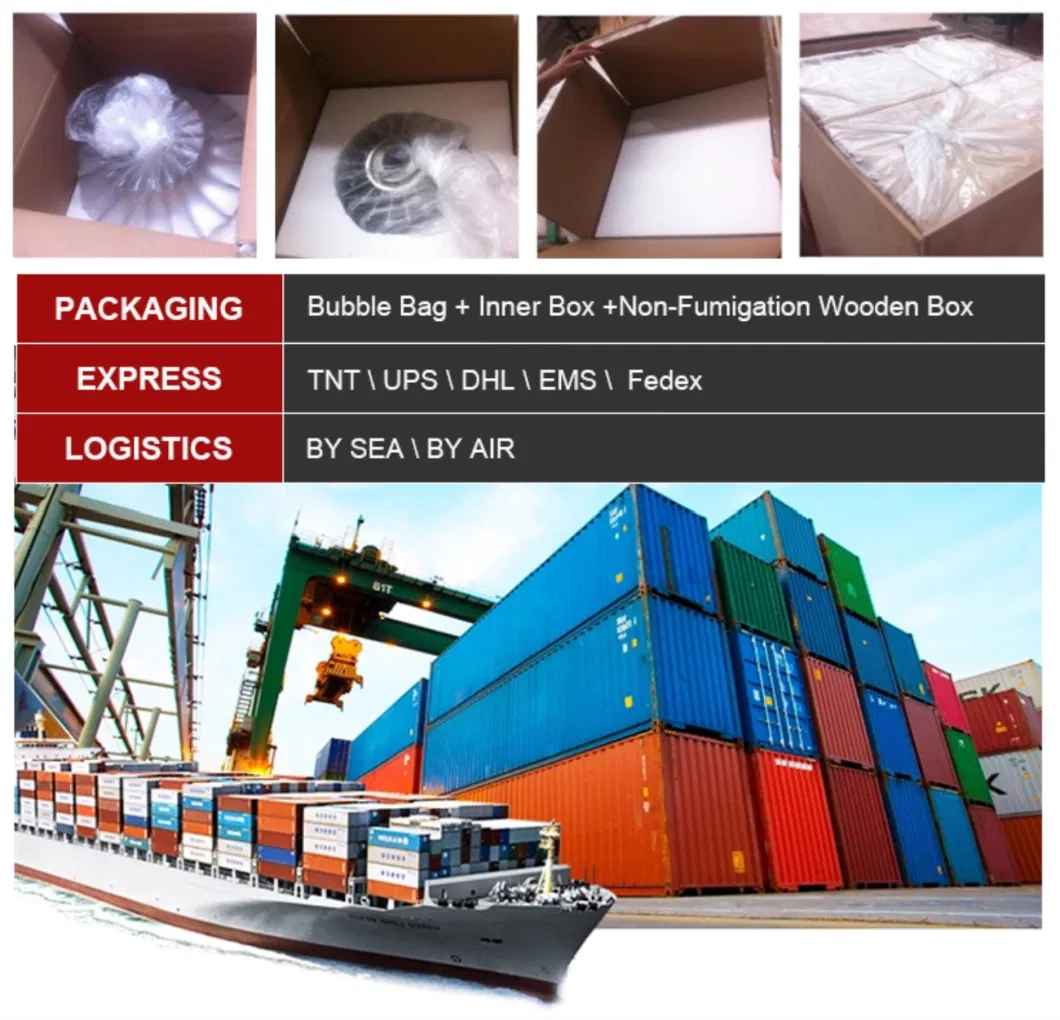

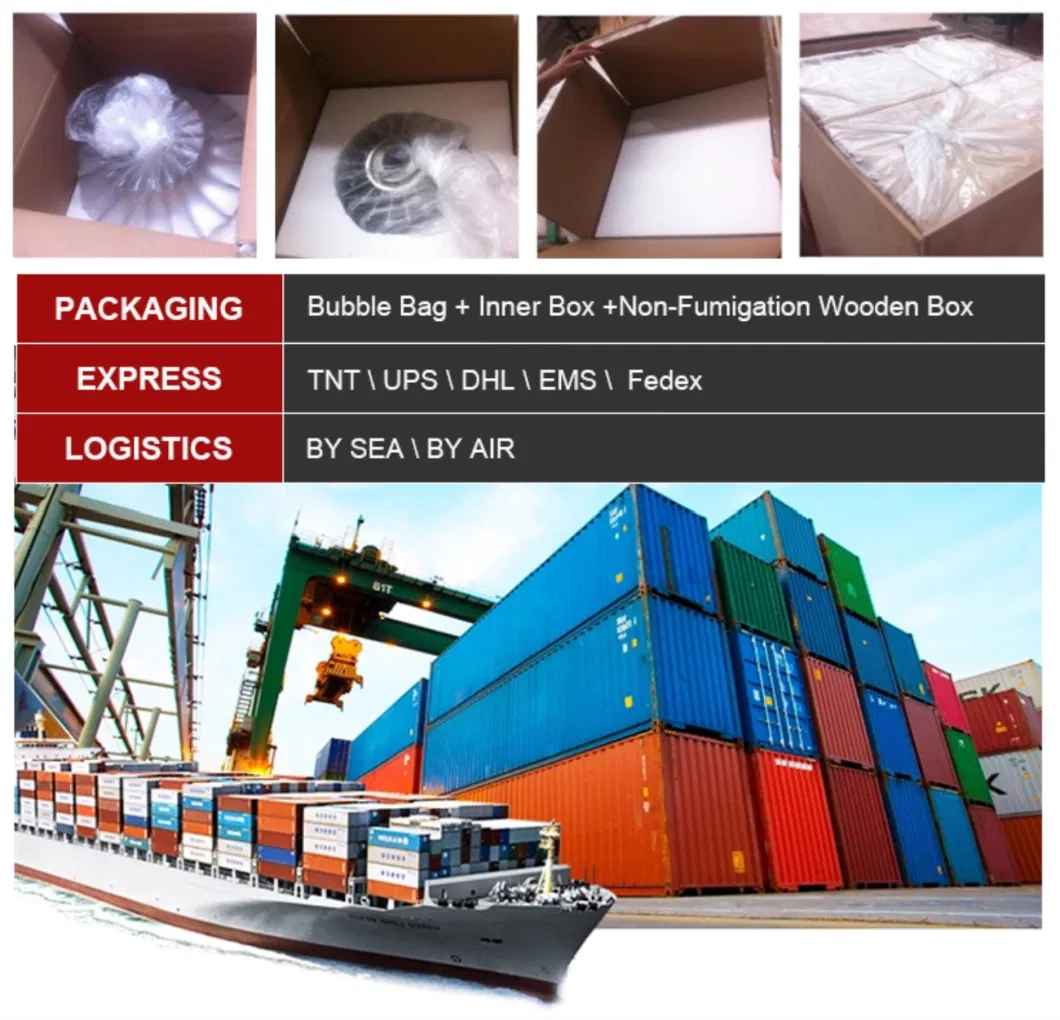

Transport Package

Bubble/Poly Bag+Carton Box

Specification

Stainless Steel

Trademark

ZEREN

Origin

Guangdong

Production Capacity

60 Tons/Month

Packaging & Delivery

Package Size

30.00cm * 20.00cm * 30.00cm

Package Gross Weight

4.000kg

Product Description

OEM Lost Wax Investment Casting Foundry/Precision Steel Casting Foundry/Cast Steel

Product Presentation

| Product Name | Vehicle Accessories |

| Brand name | Zeren |

| Model | VEA017 |

| Material | Stainless Steel |

| Classification | Transport Tool Casting Part- Vehicle Accessories |

| Process | Investment Casting + CNC machining |

| Certification | ISO9001:2015 |

| Customized support | OEM |

| Product General Specs: | |

| Material | Austenitic stainless steel: 201, 303, 304, 316, 316L, 1.4581, scs14, scs16 |

| Hardened stainless steel:17-4PH, 410, 420, 440C | |

| Alloy cast steel: 4140, 4150, 4340, 8620, GS-25CrMo4 | |

| Casting alloy tool steel: CS-2, CS-7, CrWMn | |

| Carbon steel: 1020, 1025(WCB), 1030, 1040, 1045, 1050 | |

| Weight | 1g-30kg |

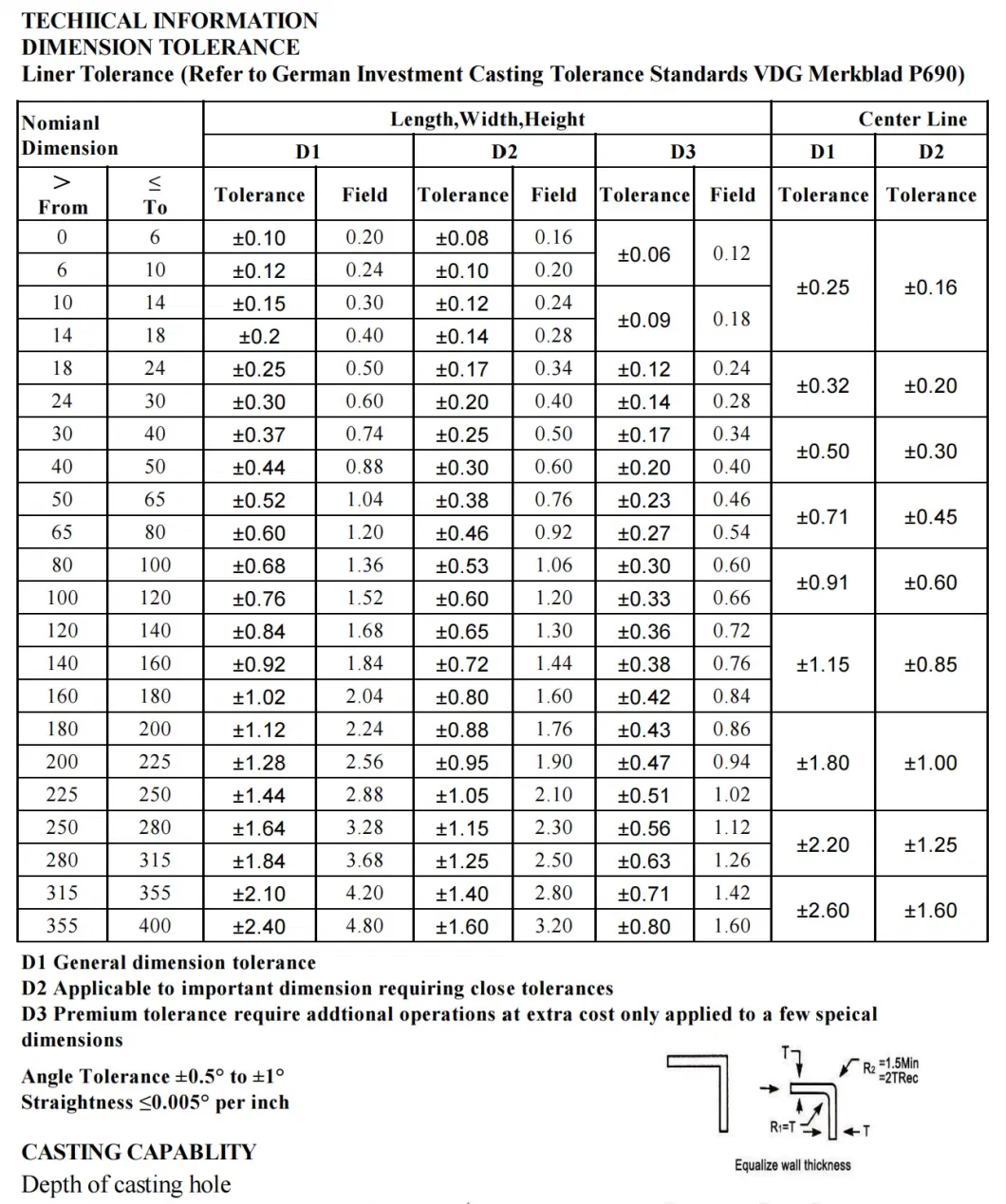

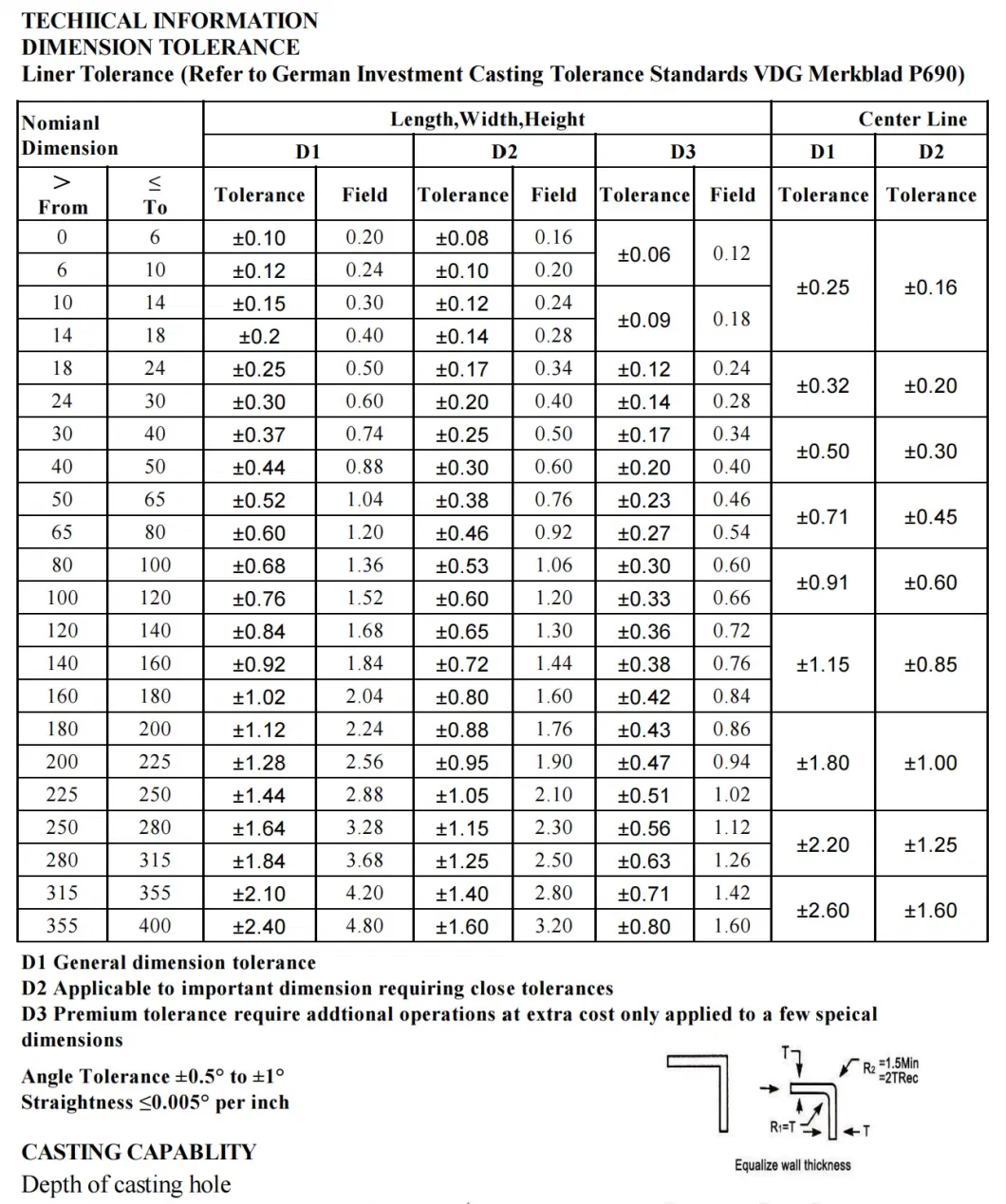

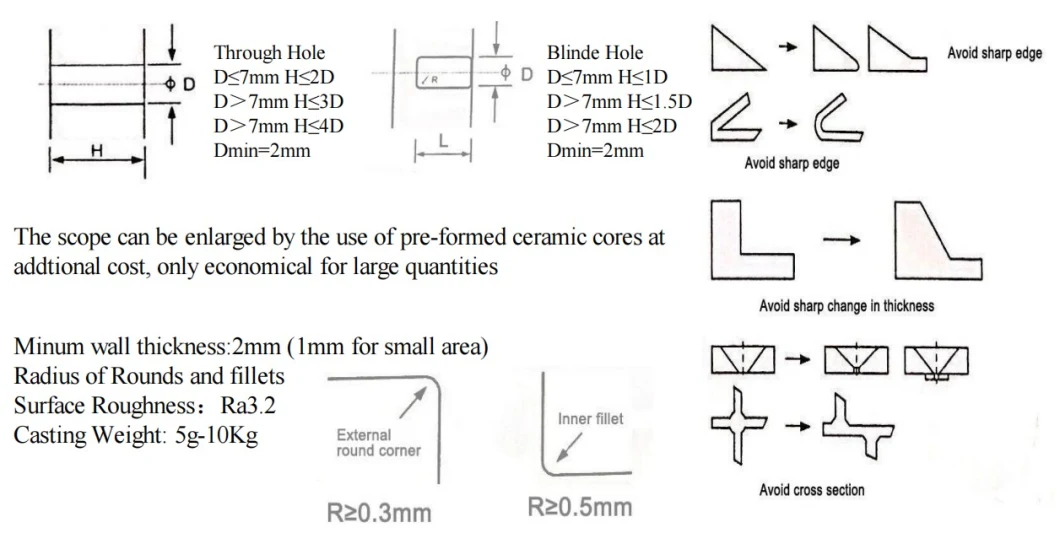

| Casting tolerance | CT4-CT7/GBT6414-1999; VDG Merkblad P690 |

| Surface Roughness | Ra1.6-Ra6.3 |

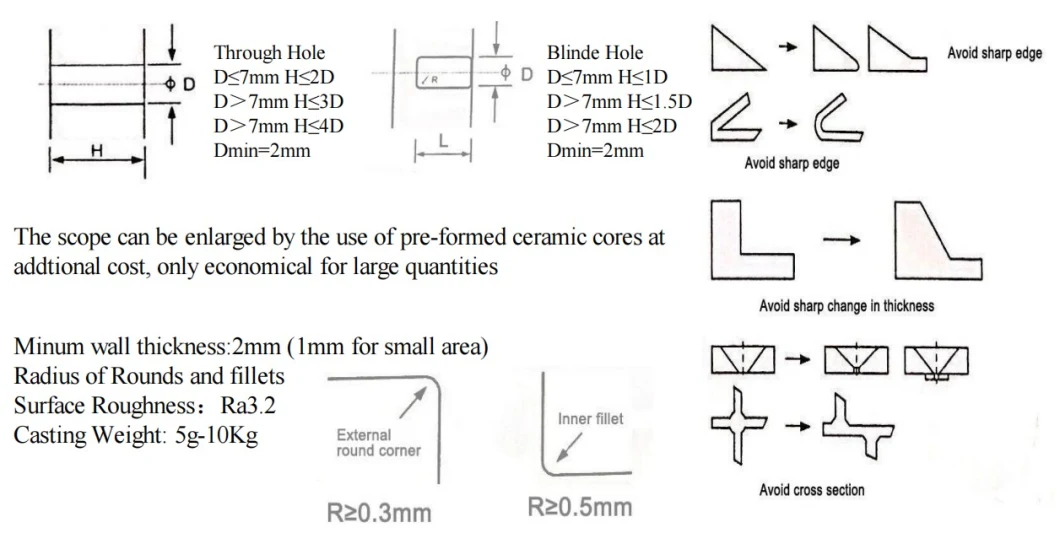

| Thickness | Min 2mm (1mm in Micro-region) |

| Casting Radius | Round radius ≥0.3mm, Internal fillet radius≥0.5mm |

| Blind Hole Depth | Max 30mm (Diamter 10mm) |

| Machining | Turning,Milling,Drilling,Boring,Threading, Grinding,CNC Machining & test equipment |

| Heat Treatment | Annealing,Hardening, Normalizing,Carburizing, Aging |

| Surface Finishing | Black Oxide,Black Coating,Anti-Pollution Flashover Coating,Mirror Polish |

| Industry Standards | ASTM, ICI, BS, DIN, JIS, ISO |

| Design Software | Pro-E, UG,Solidworks, AutoCAD |

| File Format | IGS, STP, XT, PDF, JPEG, JPG |

| Quality Control | 100% inspection before packing |

Case & Solutions

Our Case1 & Solutions:

In 2012, our company developed a product for HUAWEI: wrench casting - tool door and window hardware (As shown below), the material is A3 steel.

During the production process, we found the following problems: because the casting is easy to deform, subsequent shaping is difficult. , and after the surface is polished, it needs to be plated with copper and then chrome-plated.

At the same time, electroplating will have a magnifying effect on surface defects, and sand holes are prone to occur, resulting in rework or even scrapping after final polishing. Therefore, we recommend only casting the head of the product.

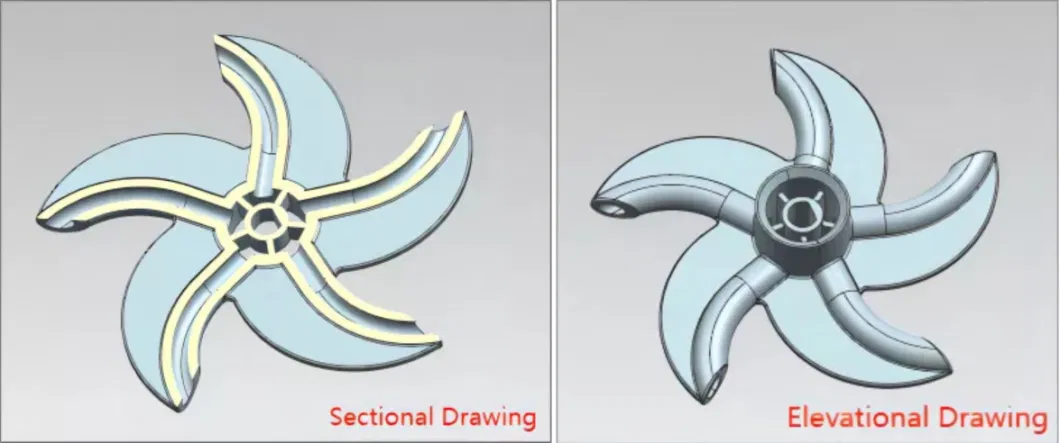

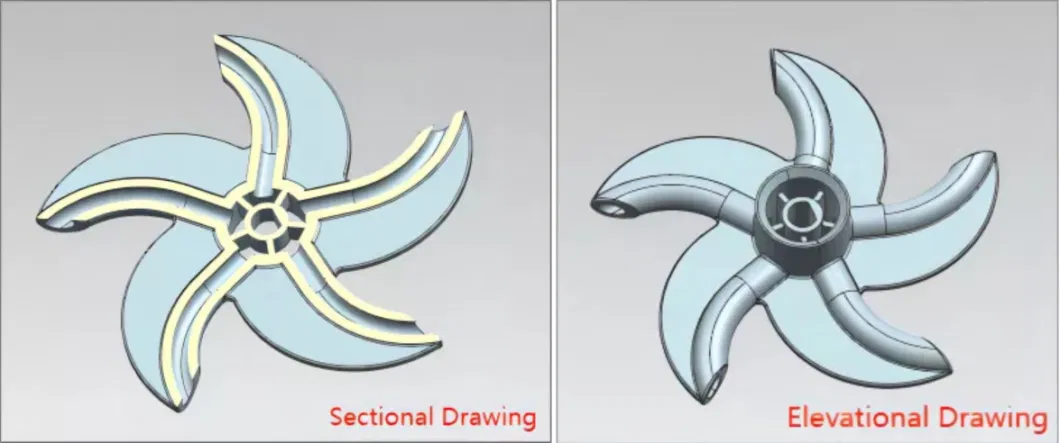

The rear plane part is processed by steel plate and then butted together, which does not affect the performance of the product, and overcomes the above defects, and reduces the cost by about 50%. 304 Stainless Steel Diffuser Impellers & Steam Valve

304 Stainless Steel Diffuser Impellers & Steam Valve

In 2016, our company produced diffuser impellers (impeller accessories) according to the drawings provided by customers (As shown below), the material is 304 stainless steel.

This product contains five curved air-dissipating holes. It is very difficult to open the mold, make the shell and remove the sand, resulting in a high scrap rate.

In this regard, after research and discussion, our engineers decided to use a sand core material that not only has high temperature strength but also is easy to remove sand after high temperature, and finally perfectly solved the problem of curved hole casting.

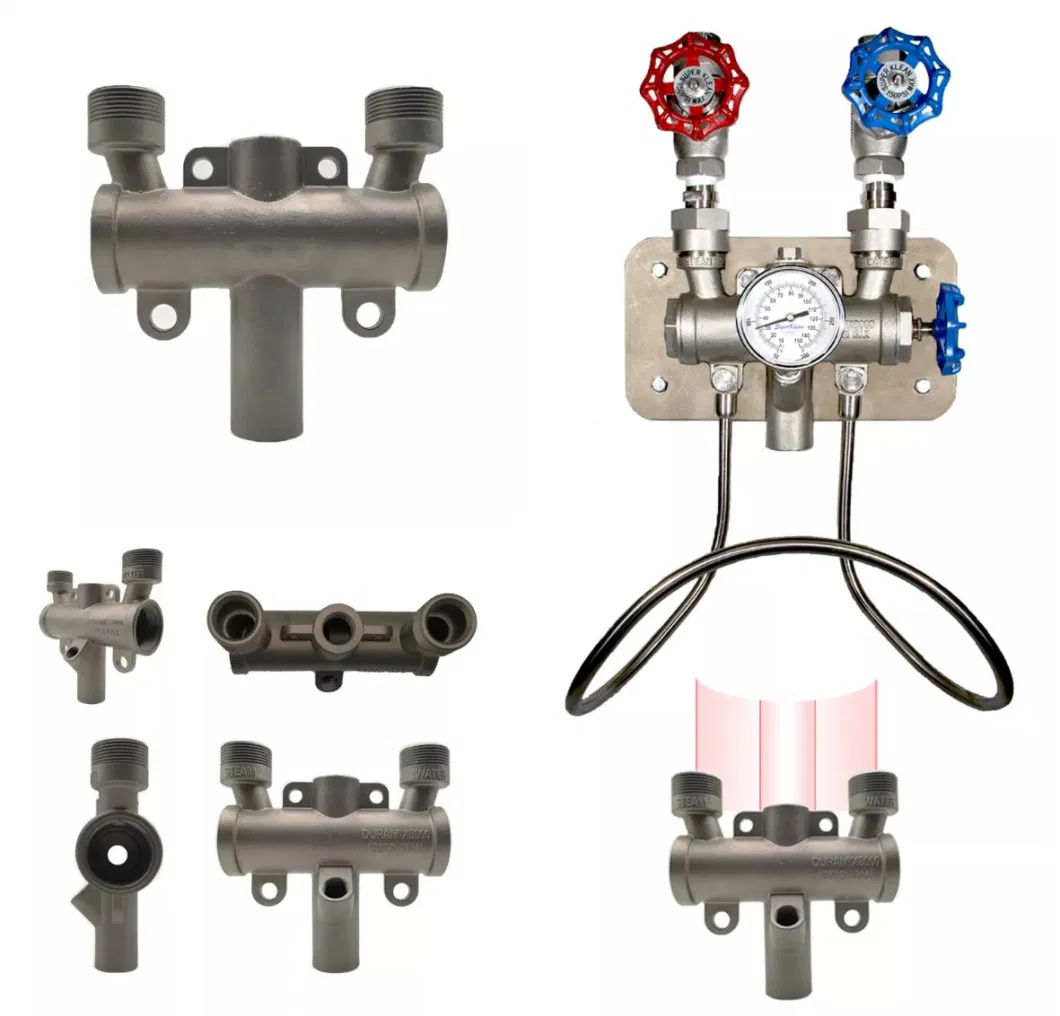

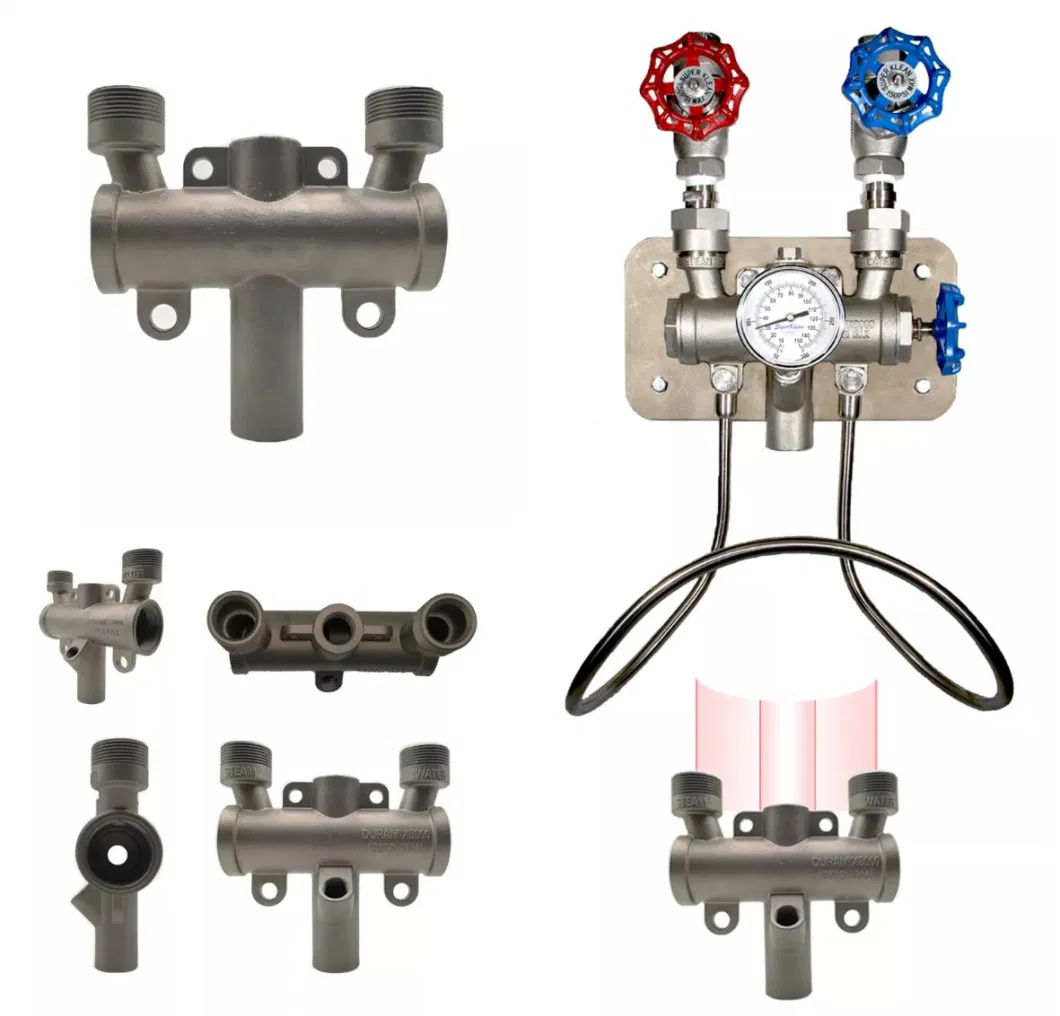

In addition, there is also a steam valve (As shown below), the material is 316 stainless steel, due to the small opening and complex inner cavity, finally successfully solved the problem for the customer by using this sand core material, produced the product, and established a long-term good cooperative relationship with the customer.

Our Case3 & Solutions:

During the production process, we found the following problems: because the casting is easy to deform, subsequent shaping is difficult. , and after the surface is polished, it needs to be plated with copper and then chrome-plated.

At the same time, electroplating will have a magnifying effect on surface defects, and sand holes are prone to occur, resulting in rework or even scrapping after final polishing. Therefore, we recommend only casting the head of the product.

The rear plane part is processed by steel plate and then butted together, which does not affect the performance of the product, and overcomes the above defects, and reduces the cost by about 50%.

Our Case2 & Solutions:

In 2016, our company produced diffuser impellers (impeller accessories) according to the drawings provided by customers (As shown below), the material is 304 stainless steel.

This product contains five curved air-dissipating holes. It is very difficult to open the mold, make the shell and remove the sand, resulting in a high scrap rate.

In this regard, after research and discussion, our engineers decided to use a sand core material that not only has high temperature strength but also is easy to remove sand after high temperature, and finally perfectly solved the problem of curved hole casting.

In addition, there is also a steam valve (As shown below), the material is 316 stainless steel, due to the small opening and complex inner cavity, finally successfully solved the problem for the customer by using this sand core material, produced the product, and established a long-term good cooperative relationship with the customer.

Our Case3 & Solutions:

316 Stainless Steel Pressure Vent Valve Body

In 2018, our company produced the pressure vent valve body (valve accessories) for customers (As shown below). The material is 316 stainless steel.

Because the opening is too small, the inner cavity is small and complicated, and it is almost impossible to clean the internal sand core. Clean, so we opened a square hole on the back of the product, welded it with a stainless steel square plate, and opened a dovetail groove at the weld, which is conducive to a strong weld.

We also used a sand core that has both high-temperature strength and is easy to remove sand after high-temperature action to make this product. After the casting was processed, the air-tightness test was carried out, and was successful, so the product was mass-produced , and finally met the customer's requirements and won the trust of the customer.

Because the opening is too small, the inner cavity is small and complicated, and it is almost impossible to clean the internal sand core. Clean, so we opened a square hole on the back of the product, welded it with a stainless steel square plate, and opened a dovetail groove at the weld, which is conducive to a strong weld.

We also used a sand core that has both high-temperature strength and is easy to remove sand after high-temperature action to make this product. After the casting was processed, the air-tightness test was carried out, and was successful, so the product was mass-produced , and finally met the customer's requirements and won the trust of the customer.

Our Case4 & Solutions:

Coffee Pot Casting Part

In 2020, our company produced the main casting of the coffee pot - kitchenware and bathroom hardware for an Italian customer (As shown below). The material is 316 stainless steel. Through communication with the customer, we learned that the customer has verticality requirements for the center of the upper and lower parts of the casting, but due to The inner cavity of this product is complex, and it is impossible to make a mold as a whole.

Therefore, we divided the wax mold of the part into upper and lower parts and made them separately, and then assembled the wax molds of the upper and lower parts into a whole.

The combined wax mold successfully passed the verticality tooling inspection procedure. , and finally all aspects of performance have met the customer's requirements, so the customer is very satisfied with our professional technical level and perfect product quality.

Therefore, we divided the wax mold of the part into upper and lower parts and made them separately, and then assembled the wax molds of the upper and lower parts into a whole.

The combined wax mold successfully passed the verticality tooling inspection procedure. , and finally all aspects of performance have met the customer's requirements, so the customer is very satisfied with our professional technical level and perfect product quality.

Our Advantage:

Water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. Silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold.

The silica sol investment casting can get a better surface roughness Ra3.2.

Company Introduction

Foshan Zeren Precision Casting Co.,Ltd. is founded in 2009, with a precision casting plant and a mechanical processing plant, located in Zhaodaxinzhao Industry Park in Shishan Town of Nanhai District of Foshan City, Guangdong province.

We use advanced investment casting(lost wax casting) process for precision castings production, which are made of Stainless steel, carbon steel and alloy steel. We can also provide subsequent machining of casting, and have passed and implemented the ISO9001:2015 quality management system.

Q1: What size products can you produce?

A: We can produce products of various sizes for different industries, weighing anywhere from a few ounces to as much as 250 pounds.

Q2: What materials can you cast? Can I OEM logo on the product?

A: We work with a variety of materials, including stainless steel, carbon steel, aluminum alloys, copper alloys, nickel-based alloys, and more. We can assist in material selection based on your specific requirements. Yes we can OEM logo.

Q3: What surface finish can be produced?

A: Ra3.2, and the machining finish can reach about Ra0.4. Other surface treatments can be done from electrophoresis, blackening, polishing, galvanizing to chrome plating, etc.

Q4: How to get sample?

A: Sample is acceptable. Please tell us what product you need.

Q5: What kind of CAD files can I send? How do I upload a CAD/large file to you?

A: You can send anything you run but the most beneficial are UG, STP, or Parasolid. Please email us

Q6: What's your payment policy?

A: For the sample order, our payment policy is 100% T/T payment (Telegraphic transfer payment) in advance or other payment method. For the bulk order, our payment policy is 30% T/T in advance, 70% balance should be paid 7 working days before delivery.

Q7: How long is your delivery time?

A: It depends on product quantity and specific requirements. Usually sample needs 7-10 days, mass order needs 20-50 days.

Why Choose Us

Tolerances For Investment Casting

Quality Control

Certificate

Packing&Shipping

FAQ

Look to Precise Castings for your next casting need!

Stainless Steel Casting • Carbon Steel Casting • High Alloy Casting • Low Alloy Casting

Heat or Wear Resistant Casting • Nickel Casting • Titainum Casting

Zeren Precise Casting is the #1 Investment casting company in our region.

Tolerances For Investment Casting

Quality Control

Quality Commitment

Quality is always the highest priority at Zeren.

We strive to meet and exceed all customer requirements and expectations and provide on-time delivery of defect-free casting and precision machined parts.

Certificate

Packing&Shipping

FAQ

Q1: What size products can you produce?

A: We can produce products of various sizes for different industries, weighing anywhere from a few ounces to as much as 250 pounds.

Q2: What materials can you cast? Can I OEM logo on the product?

A: We work with a variety of materials, including stainless steel, carbon steel, aluminum alloys, copper alloys, nickel-based alloys, and more. We can assist in material selection based on your specific requirements. Yes we can OEM logo.

Q3: What surface finish can be produced?

A: Ra3.2, and the machining finish can reach about Ra0.4. Other surface treatments can be done from electrophoresis, blackening, polishing, galvanizing to chrome plating, etc.

Q4: How to get sample?

A: Sample is acceptable. Please tell us what product you need.

Q5: What kind of CAD files can I send? How do I upload a CAD/large file to you?

A: You can send anything you run but the most beneficial are UG, STP, or Parasolid. Please email us

Q6: What's your payment policy?

A: For the sample order, our payment policy is 100% T/T payment (Telegraphic transfer payment) in advance or other payment method. For the bulk order, our payment policy is 30% T/T in advance, 70% balance should be paid 7 working days before delivery.

Q7: How long is your delivery time?

A: It depends on product quantity and specific requirements. Usually sample needs 7-10 days, mass order needs 20-50 days.