Basic Info.

Packaging & Delivery

Product Description

HSS Metric M35 Cobalt Steel Extremely Heat Resistant Twist Drill Bit with Straight Shank to Cut Through Hard Metals Such as Stainless Steel and Cast Iron

Descriptions of HSS Drill Bits For Metal:

- Cobalt Steel - Manufactured From M35 5% Cobalt Steel, With Molybdenum And Cobalt Added To Creates A Hardened Alloy, Measuring Rockwell Hardness Up To 65, For Much Faster Cutting And Extra Longer Life Span, With Up To 10 Times When Compared with an Average HSS Drill Bit.

- HSS Titanium Coating - Classic HSS Construction With Titanium Coating For Capability And Durability. The Cutting Edge Is Hardened And Honed For Sharpness.

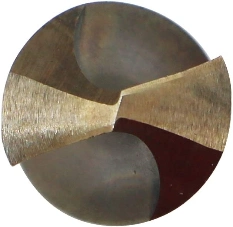

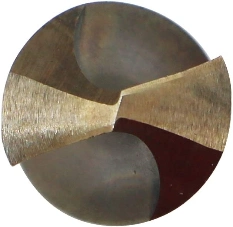

- Flutes Form - 2 Flutes Form Helps Clear Chips And Debris Away From The Bit, Decreasing Friction And Heat For A Faster, Cooler Drilling Process, Chatter-Free Design With Staggered Cutting Teeth Ensure The Precise Countersinking And Hole Smooth Clean.

- Straight Shank And 135° Point Angle - Straight Shank For Standard Drill Chucks And Collet Chuck To Hold Firmly, Assuring Accurate Centering; Helical Flute For Swarf To Easily Get Out; Ideal For General Purpose Drilling Applications.

- For Metalworking - Particularly Successful In Cutting Through Hard Metals(Hardness Less Than Hrc38°) Such As Stainless Steel And Cast Iron, Although They Can Be Used For Softer Materials Like Copper And Aluminium, Too. Not For Hardened Steel And High Carbon Steel.

1. Material and Hardness of High Speed Steel:

| DESCRIPTION OF HSS | C | W | Mo | Cr | V | Co | Si | Mn | P | S |

| % | % | % | % | % | % | % | % | % | % | |

| W2MoCr4V(F4341) | 0.95-1.05 | 1.7-2.4 | 0.8-1.2 | 3.8-4.4 | 0.8-1.2 | 1.0-1.4 | 0.2-0.4 | <=0.03 | <=0.03 | |

| W4Mo3Cr4V(4341) | 0.88-0.98 | 3.5-4.5 | 2.5-3.5 | 3.8-4.4 | 1.2-1.8 | 0.5-1.2 | 0.2-0.4 | <=0.03 | <=0.03 | |

| W9Mo3Cr4V(9341) | 0.77-0.87 | 8.5-9.5 | 2.7-3.3 | 3.8-4.4 | 1.3-1.7 | - | 0.2-0.4 | 0.2-0.4 | <=0.03 | <=0.03 |

| W6Mo5Cr4V2(M2) | 0.8-0.9 | 5.5-6.75 | 4.5-5.5 | 3.8-4.4 | 1.75-2.2 | - | 0.2-0.4 | 0.2-0.4 | <=0.03 | <=0.03 |

| W6Mo5Cr4V2Co5(M35) | 0.9-0.95 | 5.5-6.5 | 4.5-5.5 | 3.8-4.4 | 1.75-2.2 | 4.5-5.5 | 0.2-0.4 | 0.2-0.4 | <=0.03 | <=0.03 |

| W2Mo9Cr4V2Co8(M42) | 1.05-1.15 | 1.15-1.85 | 9.0-10.0 | 3.5-4.25 | 0.95-1.25 | 7.75-8.75 | 0.15-0.65 | 0.15-0.4 | <=0.02 | <=0.025 |

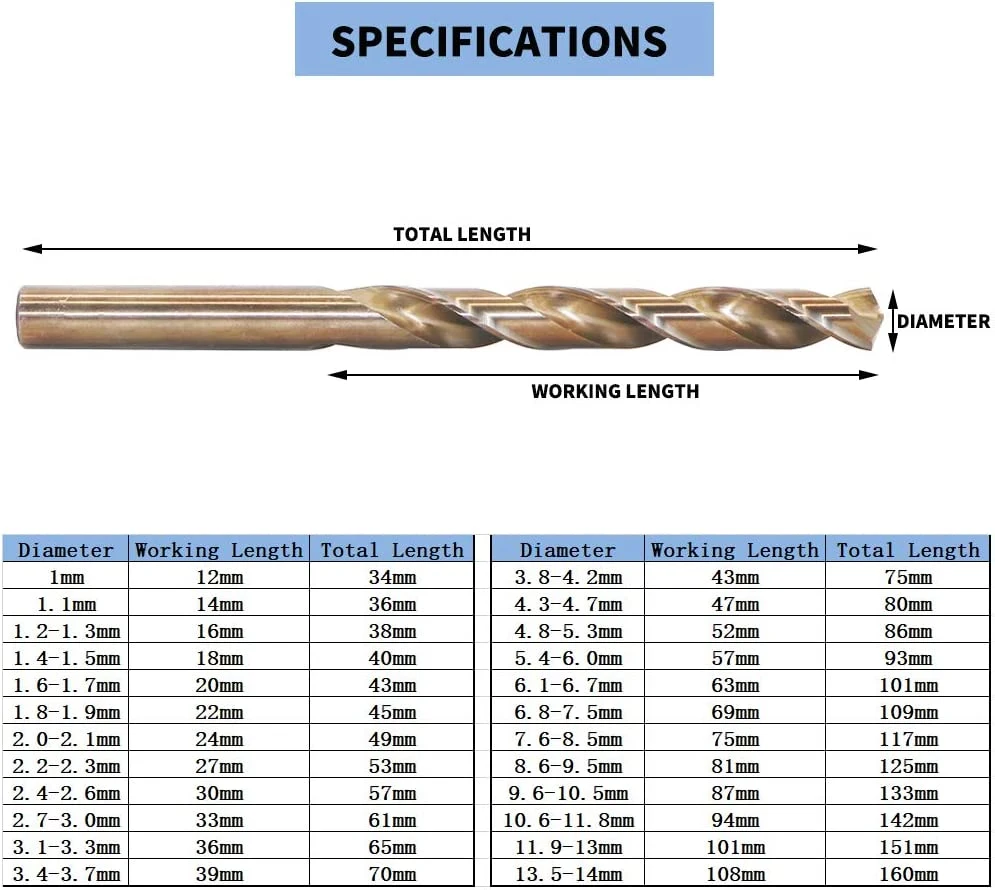

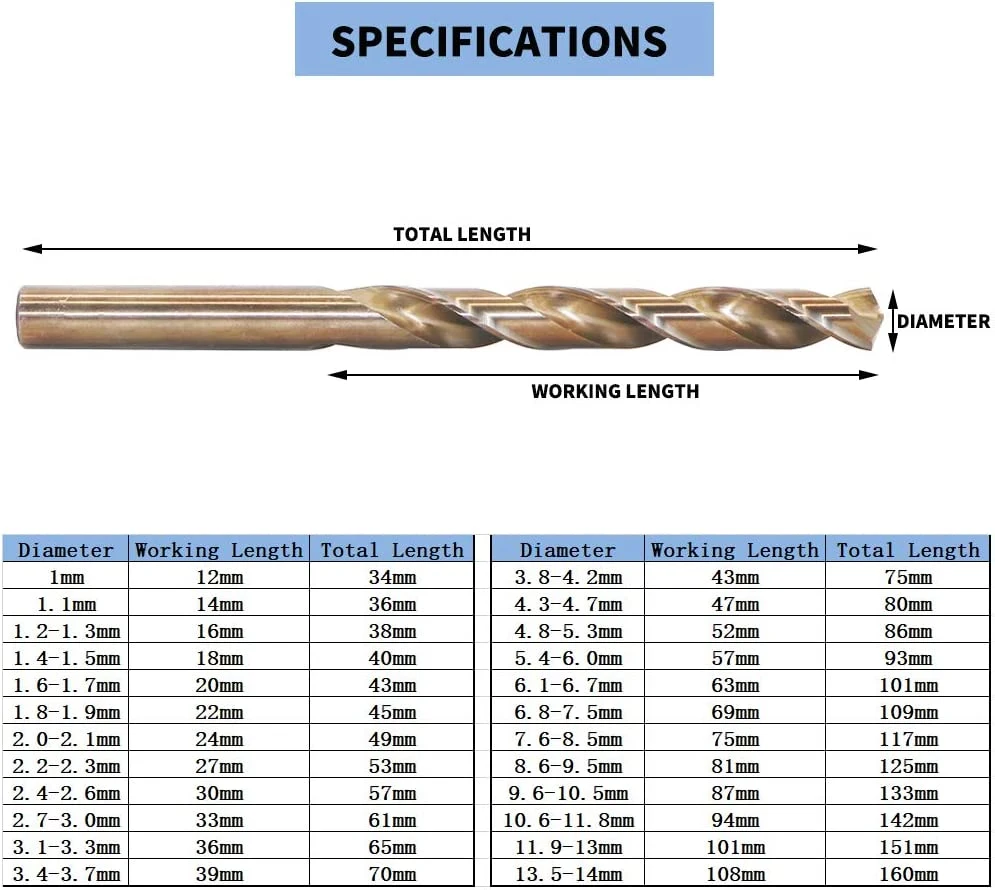

2.Size of HSS Drill Bits:

| D(mm) | L2(mm) | L1(mm) | D(mm) | L2 (mm) | L1(mm) | D(mm) | L2 (mm) | L1(mm) | D(mm) | L2 (mm) | L1(mm) |

| 0.2 | 2.5 | 19 | 1.95 | 24 | 49 | 6 | 57 | 93 | 11.2 | 94 | 142 |

| 0.22 | 2.5 | 19 | 2 | 24 | 49 | 6.1 | 63 | 101 | 11.3 | 94 | 142 |

| 0.25 | 3 | 19 | 2.05 | 24 | 49 | 6.2 | 63 | 101 | 11.4 | 94 | 142 |

| 0.28 | 3 | 19 | 2.1 | 24 | 49 | 6.3 | 63 | 101 | 11.5 | 94 | 142 |

| 0.3 | 3 | 19 | 2.15 | 27 | 53 | 6.4 | 63 | 101 | 11.6 | 94 | 142 |

| 0.32 | 4 | 19 | 2.2 | 27 | 53 | 6.5 | 63 | 101 | 11.7 | 94 | 142 |

| 0.35 | 4 | 19 | 2.25 | 27 | 53 | 6.6 | 63 | 101 | 11.8 | 94 | 142 |

| 0.38 | 4 | 19 | 2.3 | 27 | 53 | 6.7 | 63 | 101 | 11.9 | 101 | 151 |

| 0.4 | 5 | 20 | 2.35 | 27 | 53 | 6.8 | 69 | 109 | 12 | 101 | 151 |

| 0.42 | 5 | 20 | 2.4 | 30 | 57 | 6.9 | 69 | 109 | 12.1 | 101 | 151 |

| 0.45 | 5 | 20 | 2.45 | 30 | 57 | 7 | 69 | 109 | 12.2 | 101 | 151 |

| 0.48 | 5 | 20 | 2.5 | 30 | 57 | 7.1 | 69 | 109 | 12.3 | 101 | 151 |

| 0.5 | 6 | 22 | 2.55 | 30 | 57 | 7.2 | 69 | 109 | 12.4 | 101 | 151 |

| 0.52 | 6 | 22 | 2.6 | 30 | 57 | 7.3 | 69 | 109 | 12.5 | 101 | 151 |

| 0.55 | 7 | 24 | 2.65 | 30 | 57 | 7.4 | 69 | 109 | 12.6 | 101 | 151 |

| 0.58 | 7 | 24 | 2.7 | 33 | 61 | 7.5 | 69 | 109 | 12.7 | 101 | 151 |

| 0.6 | 7 | 24 | 2.75 | 33 | 61 | 7.6 | 75 | 117 | 12.85 | 101 | 151 |

| 0.62 | 8 | 26 | 2.8 | 33 | 61 | 7.7 | 75 | 117 | 12.9 | 101 | 151 |

| 0.65 | 8 | 26 | 2.85 | 33 | 61 | 7.8 | 75 | 117 | 13 | 101 | 151 |

| 0.68 | 9 | 28 | 2.9 | 33 | 61 | 7.9 | 75 | 117 | 13.1 | 101 | 151 |

| 0.7 | 9 | 28 | 2.95 | 33 | 61 | 8 | 75 | 117 | 13.2 | 101 | 151 |

| 0.72 | 9 | 28 | 3 | 33 | 61 | 8.1 | 75 | 117 | 13.3 | 108 | 160 |

| 0.75 | 9 | 28 | 3.1 | 36 | 65 | 8.2 | 75 | 117 | 13.4 | 108 | 160 |

| 0.78 | 10 | 30 | 3.2 | 36 | 65 | 8.3 | 75 | 117 | 13.5 | 108 | 160 |

| 0.8 | 10 | 30 | 3.3 | 36 | 65 | 8.4 | 75 | 117 | 13.6 | 108 | 160 |

| 0.82 | 10 | 30 | 3.4 | 39 | 70 | 8.5 | 75 | 117 | 13.7 | 108 | 160 |

| 0.85 | 10 | 30 | 3.5 | 39 | 70 | 8.6 | 81 | 125 | 13.8 | 108 | 160 |

| 0.88 | 11 | 32 | 3.6 | 39 | 70 | 8.7 | 81 | 125 | 13.9 | 108 | 160 |

| 0.9 | 11 | 32 | 3.7 | 39 | 70 | 880 | 81 | 125 | 14 | 108 | 160 |

| 0.92 | 11 | 32 | 3.8 | 43 | 75 | 8.9 | 81 | 125 | 14.25 | 114 | 169 |

| 0.95 | 11 | 32 | 3.9 | 43 | 75 | 9 | 81 | 125 | 14.5 | 114 | 169 |

| 0.98 | 12 | 34 | 4 | 43 | 75 | 9.1 | 81 | 125 | 14.75 | 114 | 169 |

| 1 | 12 | 34 | 4.1 | 43 | 75 | 9.2 | 81 | 125 | 15 | 114 | 169 |

| 1.05 | 12 | 34 | 4.2 | 43 | 75 | 9.3 | 81 | 125 | 15.25 | 120 | 178 |

| 1.1 | 14 | 36 | 4.3 | 47 | 80 | 9.4 | 81 | 125 | 15.5 | 120 | 178 |

| 1.15 | 14 | 36 | 4.4 | 47 | 80 | 9.5 | 81 | 125 | 15.75 | 120 | 178 |

| 1.2 | 16 | 38 | 4.5 | 47 | 80 | 9.6 | 87 | 133 | 16 | 120 | 178 |

| 1.25 | 16 | 38 | 4.6 | 47 | 80 | 9.7 | 87 | 133 | 16.25 | 125 | 184 |

| 1.3 | 16 | 38 | 4.7 | 47 | 80 | 9.8 | 87 | 133 | 16.5 | 125 | 184 |

| 1.35 | 18 | 40 | 4.8 | 52 | 86 | 9.9 | 87 | 133 | 16.75 | 125 | 184 |

| 1.4 | 18 | 40 | 4.9 | 52 | 86 | 10 | 87 | 133 | 17 | 125 | 184 |

| 1.45 | 18 | 40 | 5 | 52 | 86 | 10.2 | 87 | 133 | 17.25 | 130 | 191 |

| 1.5 | 18 | 40 | 5.1 | 52 | 86 | 10.3 | 87 | 133 | 17.5 | 130 | 191 |

| 1.55 | 20 | 43 | 5.2 | 52 | 86 | 10.4 | 87 | 133 | 17.75 | 130 | 191 |

| 1.6 | 20 | 43 | 5.3 | 52 | 86 | 10.5 | 87 | 133 | 18 | 130 | 191 |

| 1.65 | 20 | 43 | 5.4 | 57 | 93 | 10.6 | 87 | 133 | 18.5 | 135 | 198 |

| 1.7 | 20 | 43 | 5.5 | 57 | 93 | 10.7 | 94 | 142 | 18.75 | 135 | 198 |

| 1.75 | 22 | 46 | 5.6 | 57 | 93 | 10.8 | 94 | 142 | 19 | 135 | 198 |

| 1.8 | 22 | 46 | 5.7 | 57 | 93 | 10.9 | 94 | 142 | 19.25 | 140 | 205 |

| 1.85 | 22 | 46 | 5.8 | 57 | 93 | 11 | 94 | 142 | 19.5 | 140 | 205 |

| 1.9 | 22 | 46 | 5.9 | 57 | 93 | 11.1 | 94 | 142 | 19.75 | 140 | 205 |

| 20 | 140 | 205 |

Material of HSS M35:

Material of HSS M35:

M35 cobalt-containing stainless steel twist drill is one of the twist drills. It is named after the cobalt contained in the material. Most of them are used to process stainless steel. they have higher hardness and higher precision.

Spiral flutes, edge flutes

Enlarge the chip flute to prevent chip accumulation, drilling smoothly, and the edge groove design can effectively prevent the accumulation of chips.

Universal round shank for tight grip and no slippage

Universal round shank design, easy to hold, fast and stable installation during processing, and not easy to damage.

Sharpened head for sharper cutting

Sharp and wear-resistant, not easy to chip, scientific design, keep improving.

Application of Titanium Drill Bits:

Drilling holes on aluminium,plastic,wood,copper,iron,stainless steel.

Package of HSS Drill Bits for Steel:

1. Normal Package:5/10 pcs in a plastic bag,then inner box and out carton.

2. Other package:Blister card,Plastic tube,PVC pouch,according to your requirments.

3. HSS Drill bits set are available.