- Overview

- Description & Picture

- Data Sheet

- Customers

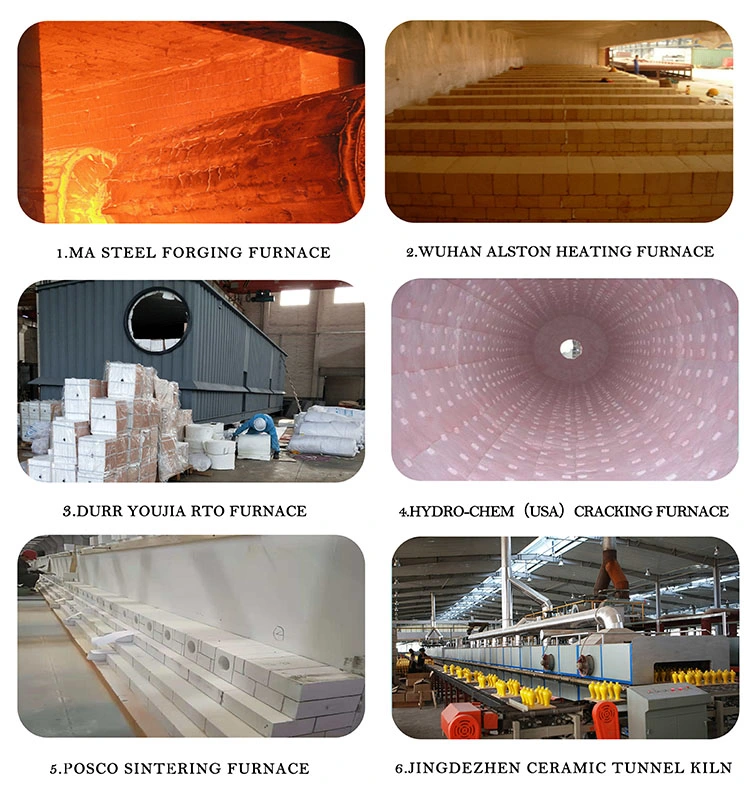

- Typical Application

- Company Profile

- Certifications

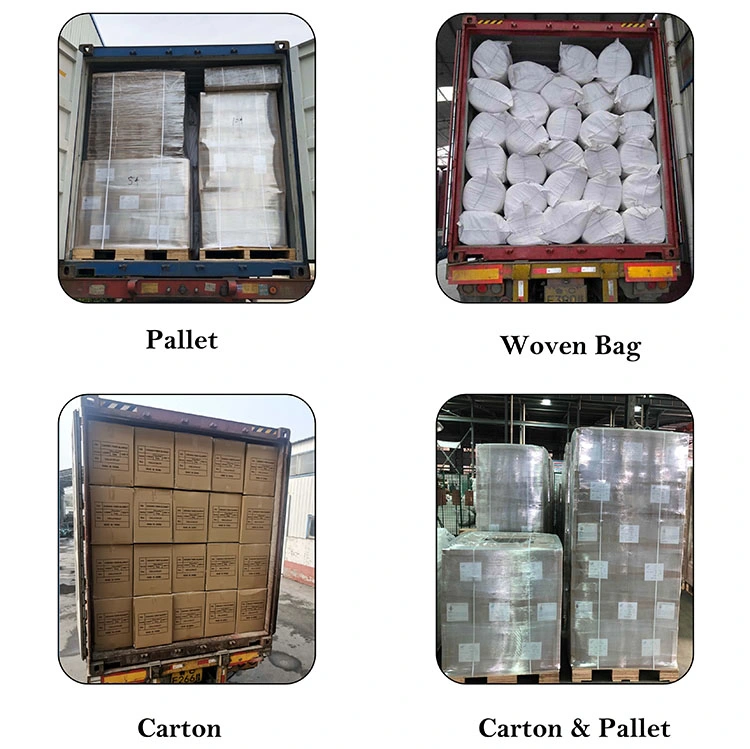

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

Monolithic Refractories Corundum Mullite Castables for Furnace Lining Insulation

CT series of castables is made from aggregate and powder , by adding binder or other admixture in it . This product is of good workability and after construction the furnace wall is of good integrity , especially suitable for the complex shape of wall lining.

| CT High-strength mullite castables | |||

| Test Item | Unit | Standard | |

| Long term working temperature | ºC | ≤ 1300 | |

| Al2O3 | % | ≤ 70 | |

| SiO2 | % | ≤ 25 | |

| Density | g/cm3 | ≥ 2.45 | |

| Compressive Strength | 110ºCx24h | MPa | ≥ 60 |

| 1300ºCx3h | MPa | ≥ 90 | |

| Flexural strength | 110ºCx24h | MPa | ≥ 5 |

| 1300ºCx3h | MPa | ≥ 10 | |

| Linear change on reheating(1350ºCx3h) | % | ±0.5 | |

| Thermal Conductivity(400ºC) | W/m.k | ≤ 1.6 | |

| Combination method | hydraulicity | ||

| Construction methods | vibration | ||

| Material | Corundum mullite castable | Corundum castable | Chrome corundum castable | ||||

| GMC-80 | GMC-88 | GYC-92 | GYC-95 | GGYC-88 | GGYC-80 | ||

| Property | |||||||

| Chemical Composition % | Al2O3 | ≥80 | ≥88 | ≥92 | ≥95 | ≥88 | ≥80 |

| Fe2O3 | ≤0.5 | ≤0.5 | ≤0.3 | ≤0.3 | ≤0.2 | ≤0.2 | |

| Density (g/cm3) | 2.6 | 2.8 | 3.1 | 3.1 | 2.9 | 2.9 | |

| Compressive Strength at Temperature(110ºCx24h) (MPa) | ≥60 | ≥60 | ≥60 | ≥60 | ≥45 | ≥45 | |

| Permanent Linear Change on Heating(1300ºCx3h) (%) | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | |

| Maximum Working Temperature (ºC) | 1550 | 1600 | 1650 | 1700 | 1650 | 1650 | |

Jiangsu Cera Thermal Technology Co., Ltd. is formerly known as Nanjing Cera Material Technology Co., Ltd.

The main business of our company includes refractory materials production, furnace lining design and

construction of high-temperature thermal engineering, furnaces equipment, research and development

and sales of refractory material. Through years of cooperation with the British Morgan Thermal Ceramics,

we have accumulated rich experience in a good deal of engineering projects. We can provide our customers

with all kinds of high quality products, professional and customized products and engineering services according

to the actual working condition and requirements of each customer, in order to meet customers' increasing demand

of energy-saving.

Our tenet is: quality and credibility is fundamental, technology and service is the life.

- 2002 Established Nanjing Cera Material Technology Co., Ltd.

- 2005 Set up Nanjing workshop.

- 2009 Started Suzhou SLMC Thermal Insulation Materials Co., Ltd.

- 2010 Started Shandong Zibo Baoyang Refractory Fiber Co., Ltd.

- 2013 Started Thermaltec Insulation(Zhejiang)Company Limited.

- 2013 Started Jiangsu Cera Thermal Technology CO.,LTD

We obtained the quality system certification GB/T 19001-2008/ISO 9001:2008.

High-tech enterprises are under declare.

1. How to control your Quality?

A1: For each order,Jiangsu Cera Tec has a complete quality control system,We have a professional testing team

for the chemical and physical properties of the products.

2. What is your delivery time?

A2: It usually needs about 10-15 days after receiving the PO.

3. What is the MOQ of the order?

A3: Not limit,we can offer the best suggestions and solutions according to your condition..

4. Do you provide free samples?

A4: Of course,we can provide free sample for you test.

5. Can we visit your company?

A5: Yes,welcome to visit our company and taste Chinese cuisine.