Basic Info.

Model NO.

12/10

Surface Treatment

Sand Blast

Surface Roughness

Ra12.5

Standard

ASME

Certification

CE, ISO 9001:2000, ISO 9001:2008

Name

Sand Casting Spare Parts

Mqq

1 Set

OEM

Accept

Certificate

ISO 9001, Ce

Pump Type

Ah Hh M L Sp Af G

After Sales

Yes

Color

Blue, Yellow, and etc

Transport Package

Packed with Wooden Box or as Customer′s Request

Specification

CE, ISO, SGS

Trademark

Naipu Or OEM

Origin

Shijiazhuang, China

HS Code

8413709990

Production Capacity

5000 Set Per Month

Product Description

High Chrome / Chromium Cast Iron Sand Casting Spare Parts

Naipu can supply High chrome alloy iron castings according to the drawing or sample.

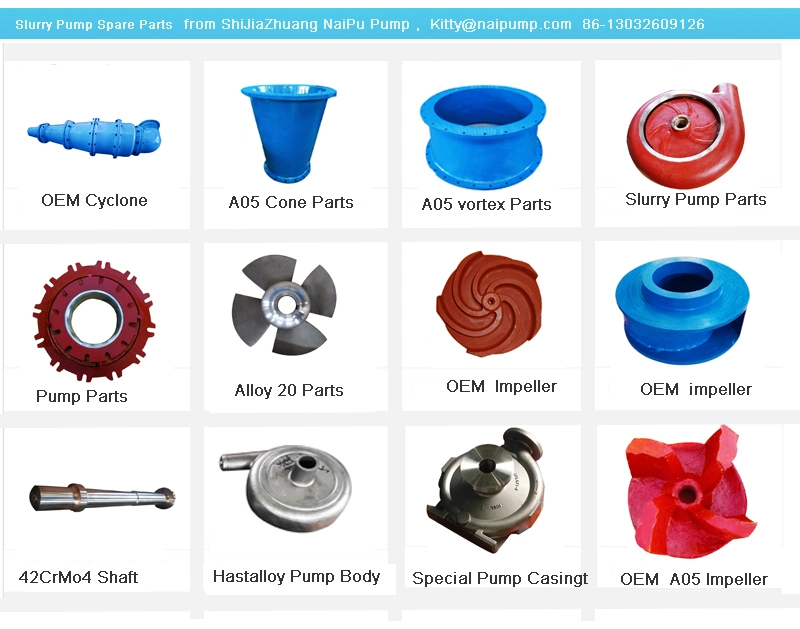

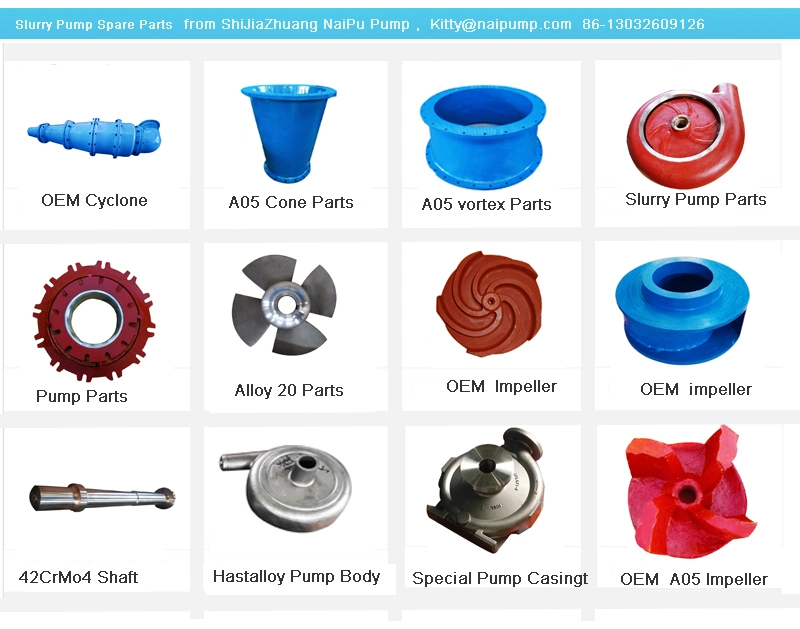

The Main material is high chorme alloy , A05, A07, A49

Material Description:

• KmTBCr27(Ultralloys®) is a wear resistant white cast iron that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of KmTBCr27 alloy is provided by the presence of hard carbides in the microstructure. KmTBCr27 Alloy is particularly suited to mild acidic duties where erosion resistance is required.

• KmTBCr28(Extralloys®) is martensitic white iron with moderate erosion resistance.It has the main elements of Chrome 28%, low Carbon with hardness of 430 in Brinell, KmTBCr28 is a corrosion resistant white iron suitable for low PH corrosion duties, where erosive wear is also a problem.

• KmTBCr35(Hyperalloys®) is a premium erosion/corrosion alloy, The main elements of Chrome is 35-45%, low Carbon with hardness of 450 in Brinell. KmTBCr35 Alloy is suitable for phosphoric acid duties, FGD duties, sulphuric acid , and other moderately corrosive applications.

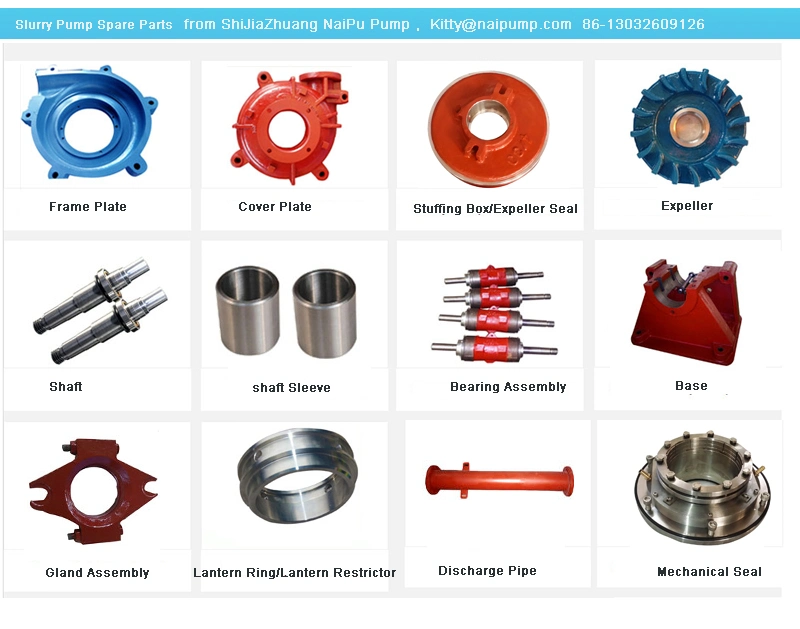

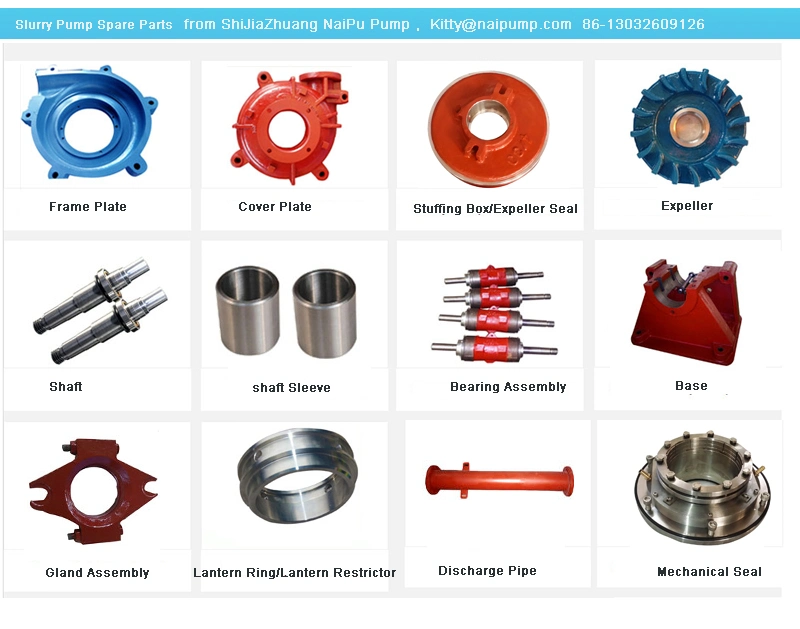

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

OEM Service

Naipu also can produce others spare parts according to the drawing or sample , also with different material. Like alloy 20 , Cast iron, ductile Iron. and ect.....

Naipu Sand Casting Foundry Workshop

Naipu Machning workshop

Naipu can supply High chrome alloy iron castings according to the drawing or sample.

The Main material is high chorme alloy , A05, A07, A49

Material Description:

• KmTBCr27(Ultralloys®) is a wear resistant white cast iron that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of KmTBCr27 alloy is provided by the presence of hard carbides in the microstructure. KmTBCr27 Alloy is particularly suited to mild acidic duties where erosion resistance is required.

• KmTBCr28(Extralloys®) is martensitic white iron with moderate erosion resistance.It has the main elements of Chrome 28%, low Carbon with hardness of 430 in Brinell, KmTBCr28 is a corrosion resistant white iron suitable for low PH corrosion duties, where erosive wear is also a problem.

• KmTBCr35(Hyperalloys®) is a premium erosion/corrosion alloy, The main elements of Chrome is 35-45%, low Carbon with hardness of 450 in Brinell. KmTBCr35 Alloy is suitable for phosphoric acid duties, FGD duties, sulphuric acid , and other moderately corrosive applications.

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

OEM Service

Naipu also can produce others spare parts according to the drawing or sample , also with different material. Like alloy 20 , Cast iron, ductile Iron. and ect.....

Naipu Sand Casting Foundry Workshop

Naipu Machning workshop

Welcome to contact us

ShiJiaZhuang NaiPu Pump Co.,Ltd

Contact person :Kitty Liu

Mobile :+86-13032609126

Shijiazhuang, Headquarters

Add.:No.368, Xinshi North Road, Shijiazhuang, Hebei Province, China