Basic Info.

Product Description

EJET 2010 Modle Eddy Current Separator:

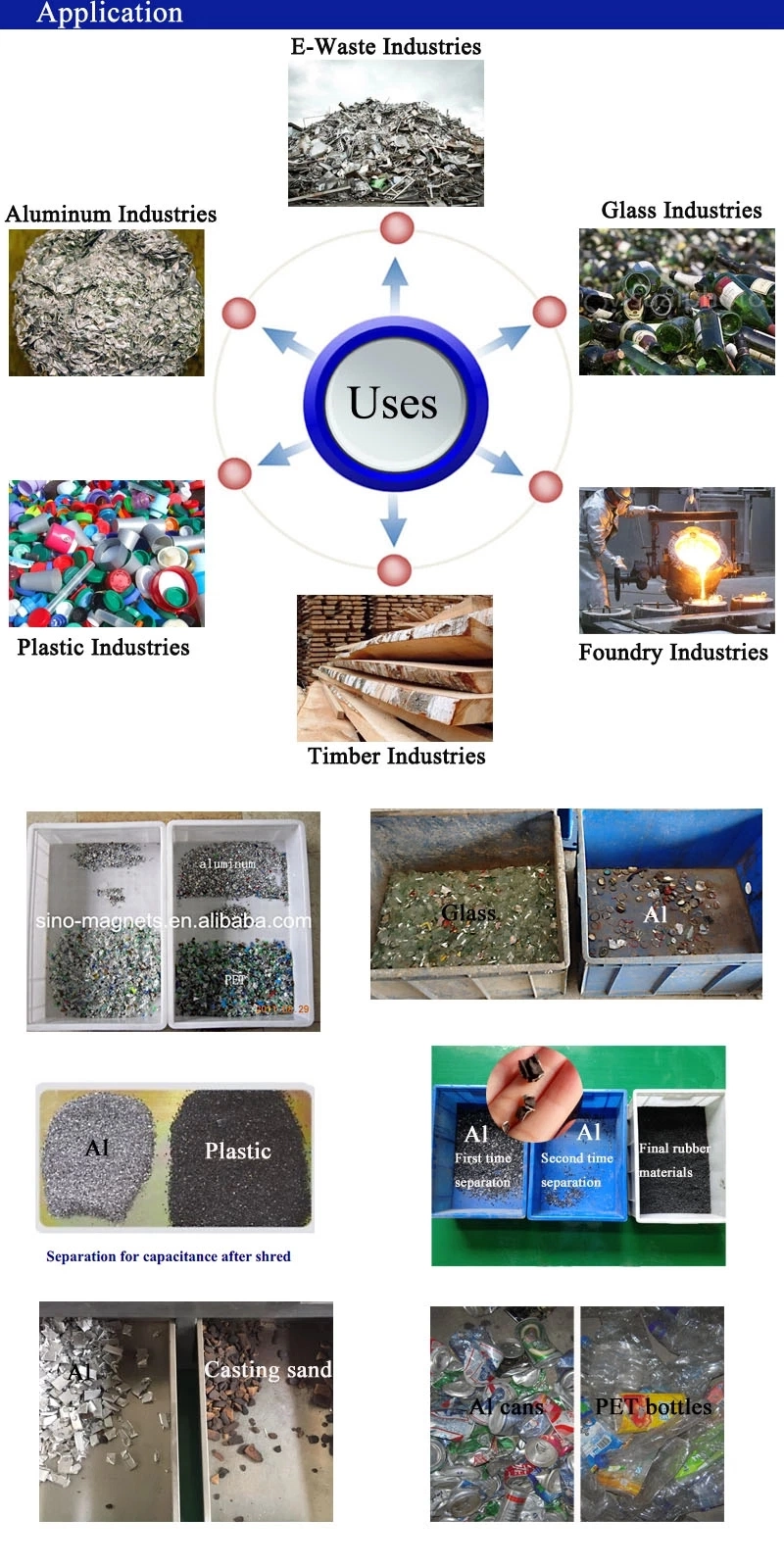

Eddy Current Separators are mainly used in industries that predominantly involve recycling such as electronics recycling (WEEE), construction, demolition, wood recycling, incineration ash, plastics recycling and Materials Recovery Facilities (MRFs).

Designed to tackle and separate non-ferrous metals such as aluminum and copper, they can effectively be used for most applications that need to eliminate non-ferrous materials from the product flow. In most applications, the ECS is used in line with other separation equipment to ensure a clean recycled product.

2010 Model ECS Eddy Current Separator |  2006 Model ECS Eddy Current Separator |

|  |

The Eddy Current Separator (ECS) is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminum and copper from dry recyclables.

Application:

Eddy induction aluminium caps and rings(conductor ) separator for crushed glass bottle (glass cullet)

This effectively and efficiently magnetic eddy induction separation machine use powerful Rare Earth permanent magnets to process through produces repelling forces for nonfeerous metal paticles separation,Ideal for the recycling industry to remove or distribute aluminum/copper/brass particles.

Eddy Current non-ferrous metallic sorting machine (ECS) is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminum, die-cast metal, copper and other value metals from nonmetallic dry recyclables.those heavy duty copper & aluminium eddy curent selection equipment are increasingly used wherever separation of non-ferrous metals from a product stream(such as plastics, glass, electronic scrap, automobile shredder residue, bottom ash, foundry sand, trash, co-mingle recyclables etc). can give a more valuable product, whether the end use is in recycling, waste reduction, raw material production or any other process whereby separation is beneficial.

Eddy current AL/CU separators is useful in situations such as:

- Separation of non-ferrous metals in auto shredder residue

- Separation of non-ferrous metals from solid waste incinerator ash

- Sorting of aluminium beverage cans from non-magnetic recyclables

- Removal of non-ferrous contamination from crushed glass cullet

- Separation of non-ferrous dross from foundry sand

- Non-ferrous metal removal in WEEE recycling plants

- Removal of aluminum components in UPVC window recycling

- Separation of non-ferrous metals from wood waste

- Separation of non-ferrous metals from plastics

- Separation of non-ferrous metals from electronic scrap

- Separation of non-ferrous metals from car recycling applications

we can design and manufacture complete magnetic conduction systems or simply furnish eddy current non-ferrous distribution drums or any other piece of magnetic separation equipment,beside these,we can also supply air classification device and nomal conveying equipment to meet your requirements.

1.Fuhusn EJET`S completely magnetic metal separation or distribution system for recycling in various industries:

| Zorba Scraps Recycling Get clean tidy aluminum flakes/scrap for future reproduction | Plastic Recycling Extracting tramp metal gets PET pure plastic flakes |

| End-of-life Cars & Automotive Recycling Industry | End-of-life Domestic Application Recycling |

| Glass recycling line gets pure glass cullet | Steel slag scraps recycling processing plant |

2. Unit magnetic metal separation/distribution equipment

- Suspended over-belt electromagnetic separator

- Over-belt suspending magnetic separator

- Magnetic block

- Eddy current nonferrous Al/Cu separator

- Magnetic drive head pulley

- Magnetic drum separator

- Magnetic plate

- Magnetic cone separator

- Grate magnetic separator

- Magnetic filter chute

- transport and handling systems such as belt conveyors/trommel drum screens/vibrator feeders

- other sorting type equipment: such as zigzag air classifier

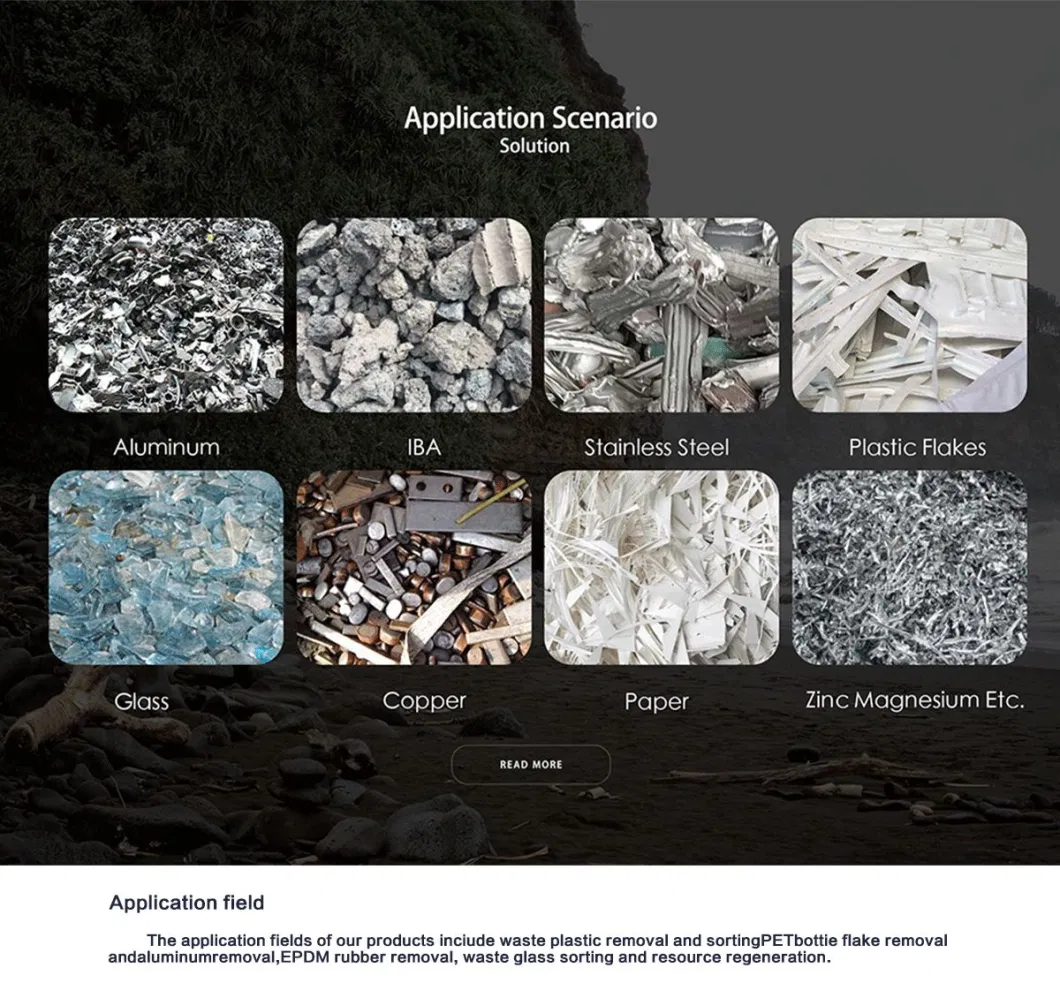

Separation Materials Display

Eddy current non-ferrous separators offer a cost-effective method of recovering up to 98% of valuable material from waste scraps. It also improves the purity of non-ferrous auto scrap up to 98-99%.

Useful in aluminum, copper, zinc etc nonferrous matal recovery from a variety of conveyed dry waste materials such as:

| ||

Separation aluminum/copper caps and rings from crushed glass bottles scrap | Recovery of aluminum/copper from crushed PET bottles | Effeciently and accuratly separation nonferrous from rubber scraps/powder |

| ||

| Beverage cans (aluminum/steel cans plastic/glass bottles) sorting from waste streams | Processing of aluminum molding sand in aluminum-shell-sand recycling lines | For wood processing industry to Separate non-ferrous metals from wood waste

|

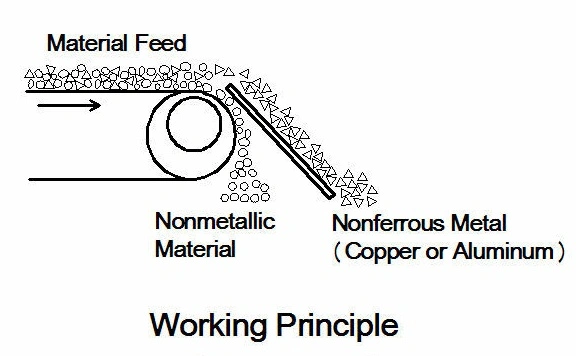

Working Principle for permanent eddy current metal sorting/clean machine:

Important: When the waste travelling over the magnetic must be in a thin layer to allow the magnetic perform to its best, in case processed metal waste is mixed with ferrous metal. The Ideal format for any metal separation is first magnetic ferrous discharge, onto a vibration conveyor to spread out and further separate the remaining metals to allow the Eddy current magnetic to work at its optimal efficiency.

EJET 2016 Modle Eddy Current Separator

|  |  |  |

Application of eddy current non-ferrous metal separator

1. Recovery Of Non-ferrous Metals From Waste Materials.

Separation of ferrous and non-ferrous metals in Shredded End-of-Life vehicle/cars (ELVs) & auto shredder residue(ASR)recycling industry

Ferrous and non-ferrous metals recovery from shredded End-of-Life domestic application

Aluminum recovery from shredded and pre-treated co-mingle recyclables metal (Zorba) recycling industry

Recovery of non-ferrous metals from slag after the incineration of municipal waste.

steel slag scraps recycling industry

crushed Bulky City waste recycling

non-ferrous dross recovery from foundry sand in aluminum-shell-sand recycling lines.

non-ferrous recovery in Waste Electrical and Electronic Equipment(WEEE) recycling plants

non-ferrous scrap from crushed waste electrolytic capacitors

2. Separation Of Non-ferrous Metals From Recyclable Materials.

non-ferrous scraps separation from cullet in glass recycling

aluminum scraps separation in UPVC window recycling.

non-ferrous components (such as brass rivets and hinges) separation in the timber recycling industry.

non-ferrous scraps separation in the plastic recycling industry

Non-ferrous scraps are separated from crushed rubber.

Aluminum cans sorted from municipal solid waste

FAQ

Q: What kind of metal is magnetic eddy current applied to?

A: suitable for crushed mixed metal scraps sorting industries

often the mixture is composed of steel, iron, etc ferromagnetic metal and aluminum, copper, and brass. etc non-ferrous scraps separation from materials of size >3mm.

Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material`s situation .including the composition, size, handling capacity and expected separation result.

Q: What are the pros and cons of a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much more suitable for the complicated material situation, The eccentric rotor design reduces long-term wear due to heated ferrous build up, and can effectively avoid the device damage caused by impurity ferrous metal.

Exclusive the ferrous influence, the concentric type has a little bit better separation effect but must make sure no ferrous exist.

For any inquire about various metal solutions, please feel free to contact with us

OTHER TYPE Introduction

How to work:

Eddy Current Separation utilizes a magnetic rotor with alternating polarity.

This spins quickly inside a non-conductive drum which in turn is driven by a conveyor belt.

The external drum is effectively used as a head pulley which rotates at belt speed.

The internal rotor rotates at a higher speed than the drum.

This creates a very strong repelling force through the induction of Eddy Currents.

Non-Ferrous metals are thrown from the product flow as they are rejected by the alternating magnetic field.

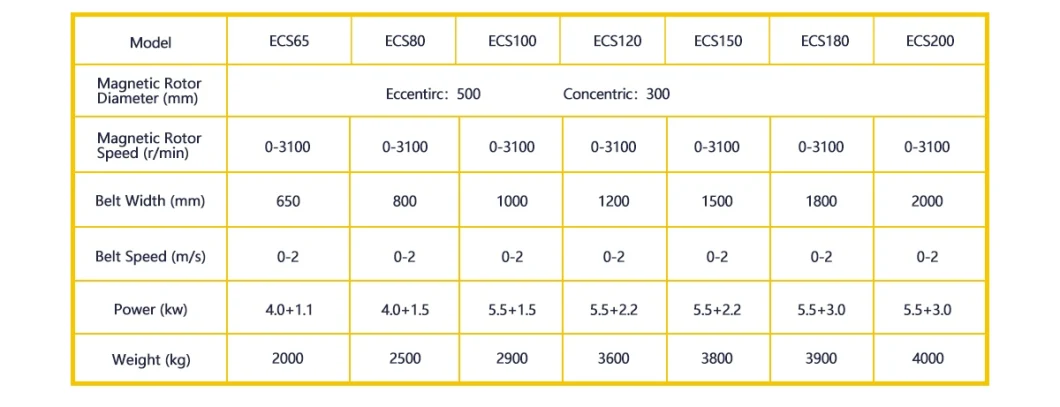

Parameters:

Model | Belt Width | Motor Power | Dimension(mm) |

|

| Weight |

| mm | Kw | Length | Width | High | Kg |

ECS-40 | 450 | 3.0/0.75 | 2080 | 1375 | 1100 | 1100 |

ECS-65 | 650 | 4.0/1.5 | 3300 | 1500 | 1200 | 1200 |

ECS-80 | 800 | 5.5/1.5 | 3300 | 1700 | 1200 | 1400 |

ECS-100 | 1000 | 5.5/1.5 | 3300 | 1900 | 1200 | 1600 |

ECS-120 | 1200 | 5.5/2.2 | 3300 | 2000 | 1200 | 1800 |

ECS-140 | 1400 | 7.5/2.2 | 3620 | 2130 | 1587 | 2100 |

ECS-150 | 1500 | 7.5/2.2 | 3420 | 2400 | 1530 | 2200 |

ECS-180 | 1800 | 7.5/2.2 | 3300 | 2700 | 1200 | 2800 |

Our Company:

1.Professional engineers and strong technical force.Our Company

2.Our main products are eddy current separator, suspended magnetic separator,lifting magnets,etc.

3.Reasonable prices,our products are extensively used in solid waste treatment, metallurgical mine, power plants, coal mining and other industries.

4.The products have been exported over thirty countries , such as: the United States, Canada, Japan and Australia and so on.

Our Service:

1.Professional engineers and strong technical force

2.Superior suppliers to keep our quality

3.Test of materials is free

4.Strict quality checked for every machine before packing

5.Engineers available to service machinery overseas

Why Choose us:

1. we have our own factory

2. Our engineers are professional

3. Our machine has been exported to over thirty countries

FAQ:

1. Q: What kind of metal is eddy current applied to?

A: Eddy Current Separator suitable for aluminum, copper, and brass.etc non-ferrous scraps separation from non-metal materials of size >3mm.

2. Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material's situation including the composition, size , handling capacity and expected separation result.

3. Q: What are the pros and cons of a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much more suitable for complicated material situations, The eccentric rotor design reduces long-term wear due to heated ferrous build up, and can effectively avoid the device damage caused by impurity ferrous metal.

Exclusive the ferrous influence, the concentric type has a little bit better separation effect, but must make sure no ferrous exist.

5. Q: How long is the machine warranty period?

a.For magnetic property:8 years ;

b.For main engine:1 years

c.For conveyor belt:6 months.

Packaging & Shipping

1. Packing: Export packing for rare earth eddy current separation equipment

2. Shipping time: 30 days after receiving the deposit

Our Services

As a professional automation and separating systems manufacturer for more than 18 years, honesty, reliability, commitment and competence are our unchanged values.

Thanks to the superior suppliers (Nord, Simens &Schneider),well-equipped professional engineers and strong technical force, we keep our consistent high quality.

Strict quality checking for every machine before packing, engineers available to service machinery overseas, in addition, there is not only after-sales service support but also technical support, "keep improving, persuing excellence" would be kept forever.

The most suitable machine would be recommended to you according to your information.