- Overview

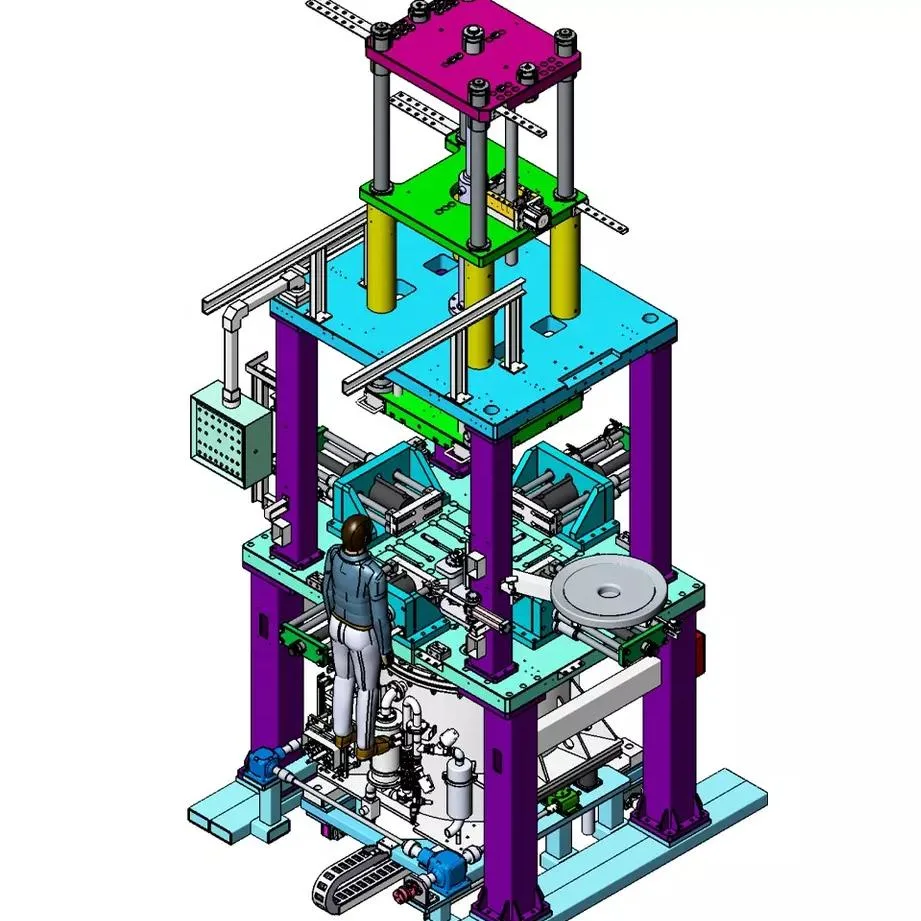

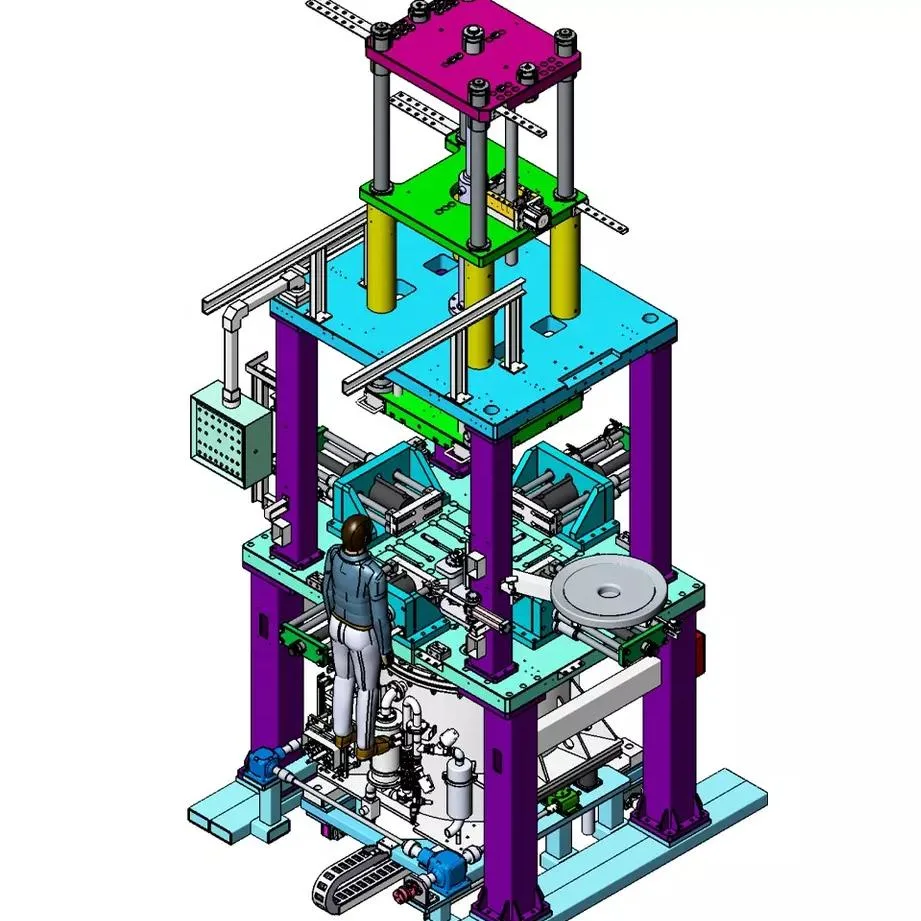

- Detailed Photos

Basic Info.

Model NO.

BQ-PWSG

Application

High Quality Aluminum Casting

Control System

Siemens PLC+HMI

Hydraulic System

Servo or Regular Motor

Oil Pump

Gear Pump

Cooling System

Water or Air or Mixed Cooling

Transport Package

Naked Package

Specification

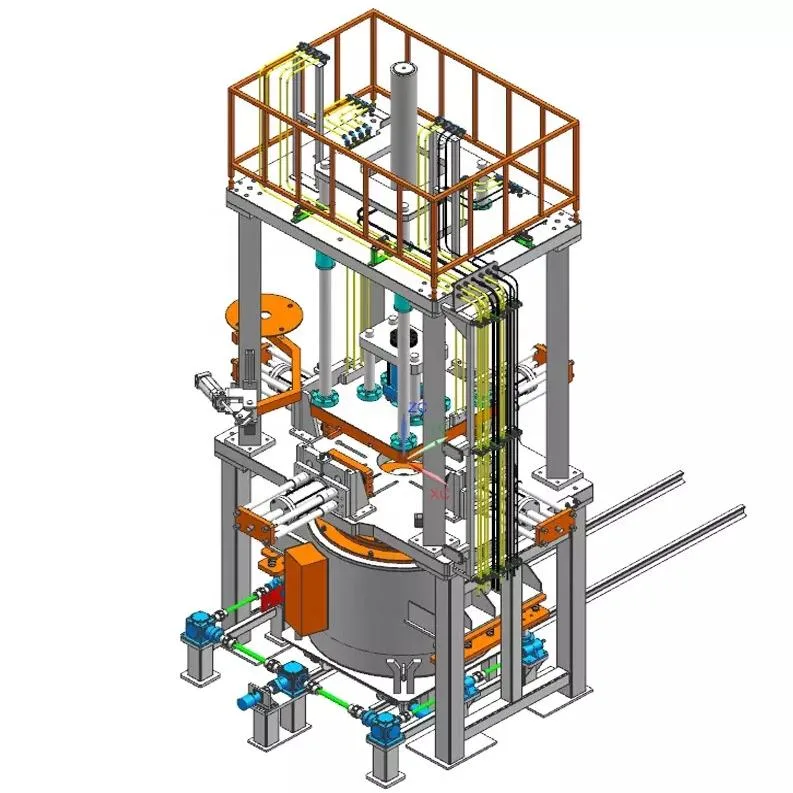

800kg holding furnace

Trademark

BOQIAO

Origin

China

HS Code

8454309000

Production Capacity

100 Set/Year

Product Description

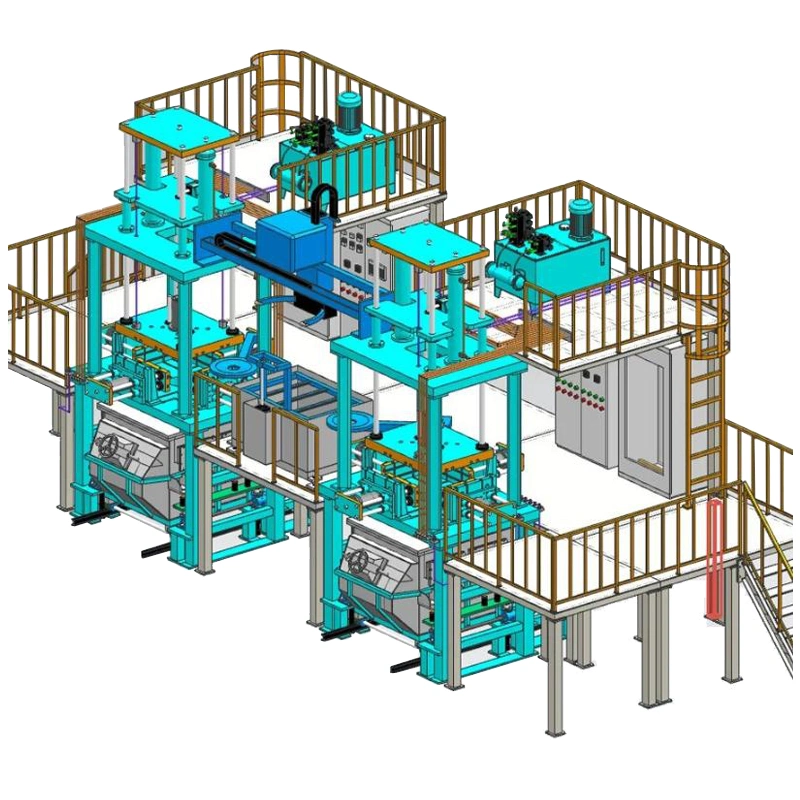

Asia Foundry Factory ASTM and BS Standards Aluminum Die Casting Machine

★Non-stick aluminum structure to reduce oxidation burn

★Full digital servo hydraulic system, or variable frequency hydraulic system, saving energy by more than 50%

★90° installation mold (reverse installation)

★Ultra-high pressure accuracy

★High productivity

★Fully automatic cycle

★Full hydraulic power drive

★Reverse top stripping

★High rigidity, high strength and high reliability

★Energy saving and eco-friendly

Features of Product:

1. Siemens PLC+HMI semi-automatic operation, high efficiency and save labor

2. Supply solution and turnkey project service

3. Finish installation and adjustment before delivery to produce qualified product

4. Great aftersales, free parts and service

Technical Parameters:

Application Industry of Machine:

Equipment Technology Specification:

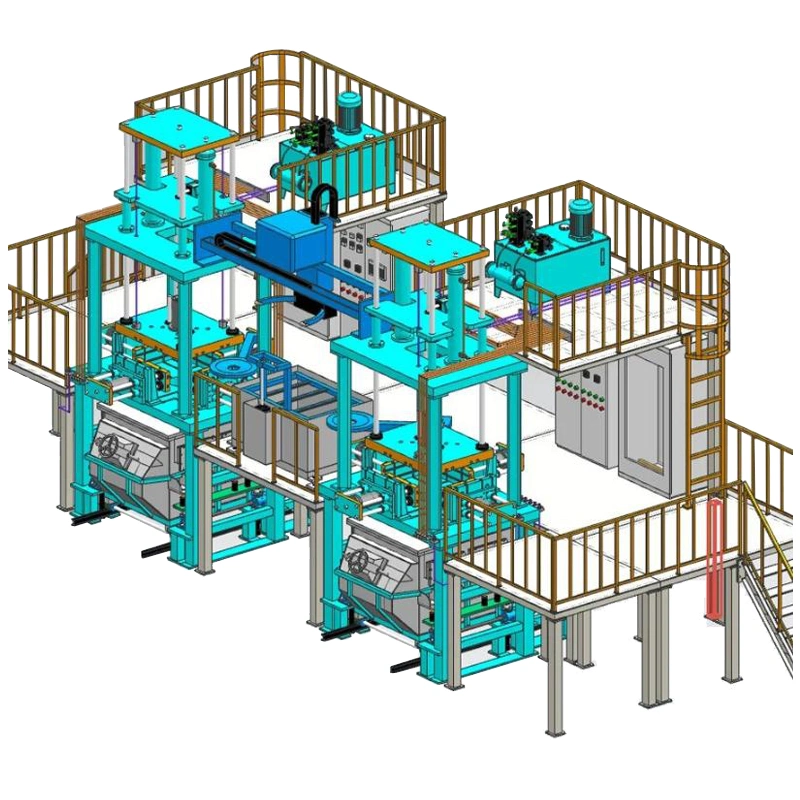

Related Equipment We Can Supply:

We can provide customers with a complete set of low-pressure casting products.The initial period,for example, the upfront budget for products not in production, including the budget for production costs, the budget for molds and equipment, and the development of production processes in the medium term, in addition to providing qualified equipment to customers.

The process of producing the product is developed, and the entire production process is handed over to the customer,training and ensuring that the customer can understand and learn, then fully grasp th e production process of low pressure casting. In the later stage, in addition to providing warranty service during the warranty period, a lifetime paid maintenance service will be provided after the warranty period.

In addition, we can also provide equipments and processes for heat treatment of aluminum alloy products, such as aluminum alloy aging furnace(T4), aluminum alloy vertical quenching furnace(T6),etc. and provide a variety of casting equipments including resistance melting furnace.

★Non-stick aluminum structure to reduce oxidation burn

★Full digital servo hydraulic system, or variable frequency hydraulic system, saving energy by more than 50%

★90° installation mold (reverse installation)

★Ultra-high pressure accuracy

★High productivity

★Fully automatic cycle

★Full hydraulic power drive

★Reverse top stripping

★High rigidity, high strength and high reliability

★Energy saving and eco-friendly

Features of Product:

1. Siemens PLC+HMI semi-automatic operation, high efficiency and save labor

2. Supply solution and turnkey project service

3. Finish installation and adjustment before delivery to produce qualified product

4. Great aftersales, free parts and service

Technical Parameters:

| Installation method of holding furnace | Fixed | Mobile |

| Holding furnace capacity | 500kg | 500kg |

| Table size | 1400*1400mm | 1500*1500mm |

| Moving template size | 800*800mm | 800*800mm |

| Distance between moving template and workbench | 450-1450mm | 450-1450mm |

| Moving template stroke | 1000mm | 1000mm |

| Inner dimensions of workbench column | 1050*980mm | 1050*1150mm |

| Ejection stroke | 50mm | 50mm |

| Mold cooling | 10 cooling lines | 10 cooling lines |

Application Industry of Machine:

Equipment Technology Specification:

LPDC Machine Technology Specification | ||||

| Parameter | Unit | J452L | J455L | J458L |

| Machine body | ||||

| Fixed columns clearance | mm | 1050*750 | 1400*1000 | 1750*1250 |

| Distance between mobile and fixed platen | mm | 450-900 | 500-1350 | 550-1800 |

| Side cylinder stroke | mm | 250 | 300 | 450 |

| Opening force of the upper cylinder | KN | 122 | 177 | 245 |

| Closing force of the upper cylinder | KN | 94 | 138 | 305 |

| Opening force of side cylinder | KN | 59 | 94 | 165 |

| Closing force of side cylinder | KN | 78 | 122 | 212 |

| Ejection force | KN | 122 | 177 | 305 |

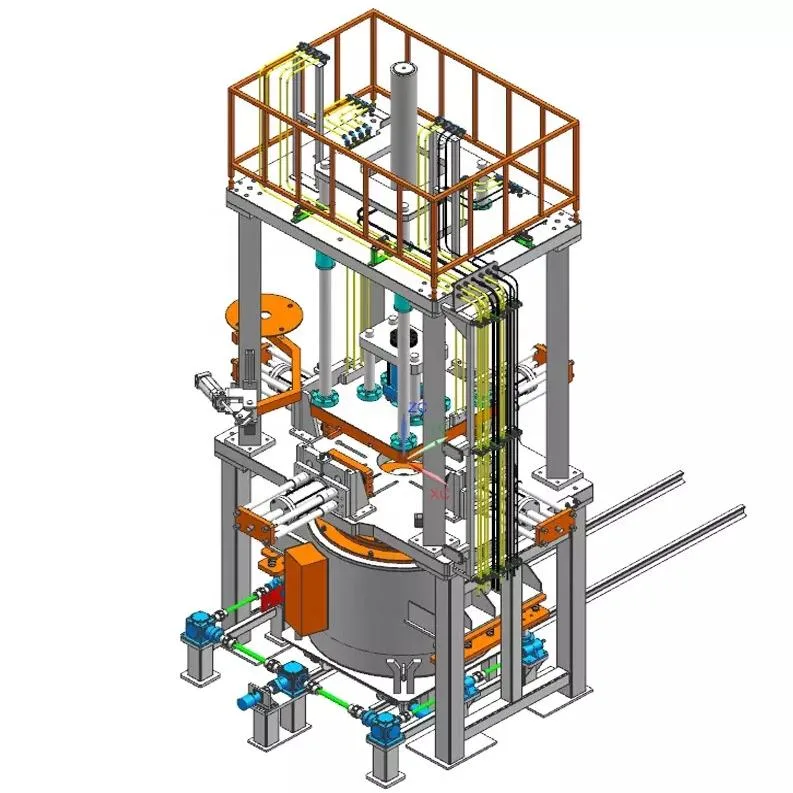

| Holding furnace | ||||

| Furnace type | crucible | crucible or refractory | ||

| Capacity | KG | 300 | 500 | 800 |

| Power rate | KW | 20 | 30 | 40 |

| Temperature control accuracy | ±ºC | 2 | 2-5 | |

| Furnace pressure | Bar | Max. 1.5 bar | ||

| Hydraulic pump station system | ||||

| Motor type (Regulation or Servo) | optional | |||

| Motor power rate | KW | 5.5 | 15 | 18.5 |

| Hydraulic pressure | Bar | Min. 80 bar -max. 120 bar | ||

| Pump type (gear or plunger) | Optional | |||

| Cooling type | Air | Air or water | Water | |

| Cooling water consumption | L/Min | 40 | 50 | |

| Operation control system | ||||

| PLC, HMI unit | Siemens | |||

| Operation method | Automatic | |||

| Main power voltage (380V 60HZ,400V 50HZ) | V, HZ | Optional | ||

| Auxiliary power voltage | V, HZ | 24 | ||

| Control cabinet cooling type | Fan | Fan or air conditioning | ||

Related Equipment We Can Supply:

We can provide customers with a complete set of low-pressure casting products.The initial period,for example, the upfront budget for products not in production, including the budget for production costs, the budget for molds and equipment, and the development of production processes in the medium term, in addition to providing qualified equipment to customers.

The process of producing the product is developed, and the entire production process is handed over to the customer,training and ensuring that the customer can understand and learn, then fully grasp th e production process of low pressure casting. In the later stage, in addition to providing warranty service during the warranty period, a lifetime paid maintenance service will be provided after the warranty period.

In addition, we can also provide equipments and processes for heat treatment of aluminum alloy products, such as aluminum alloy aging furnace(T4), aluminum alloy vertical quenching furnace(T6),etc. and provide a variety of casting equipments including resistance melting furnace.